Machining method for inside hexagonal bolt

A processing method, the technology of hexagonal bolts, applied in the direction of bolts, threaded fasteners, connecting components, etc., can solve the problems of long cutting processing time, large tool loss, waste of raw materials, etc., achieve fast deformation, improve quality, and improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

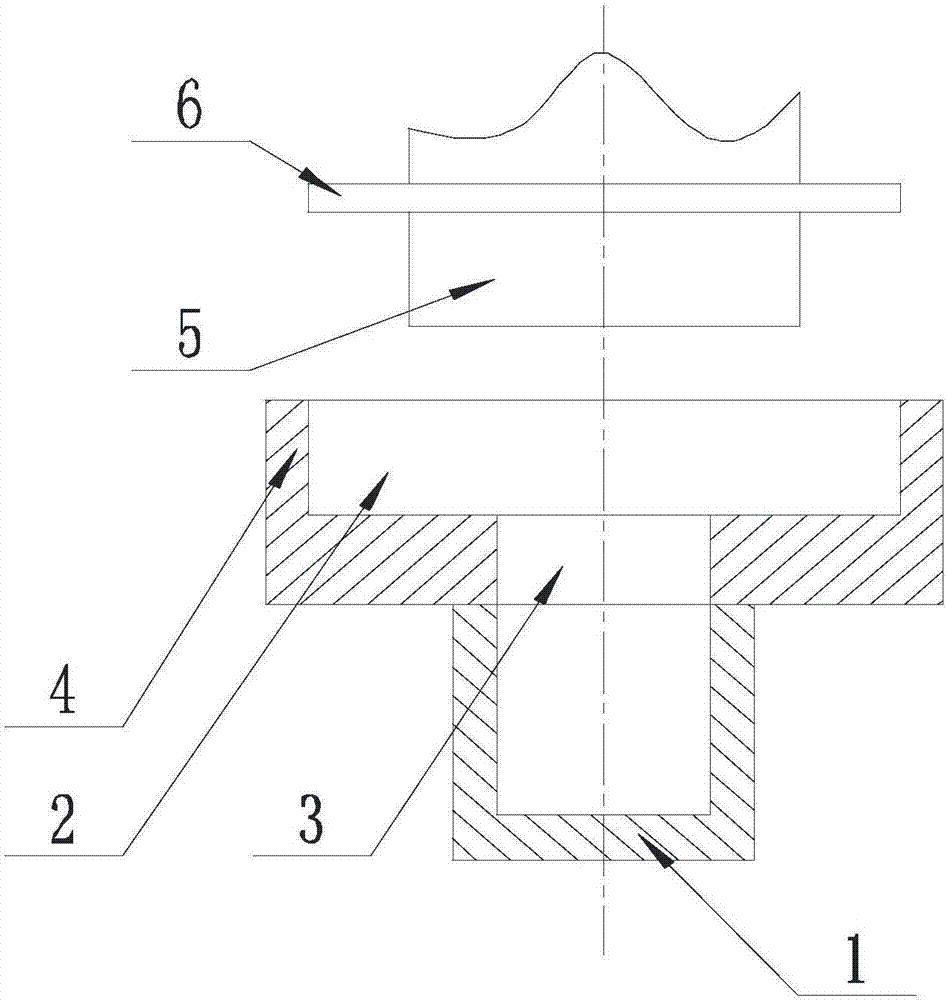

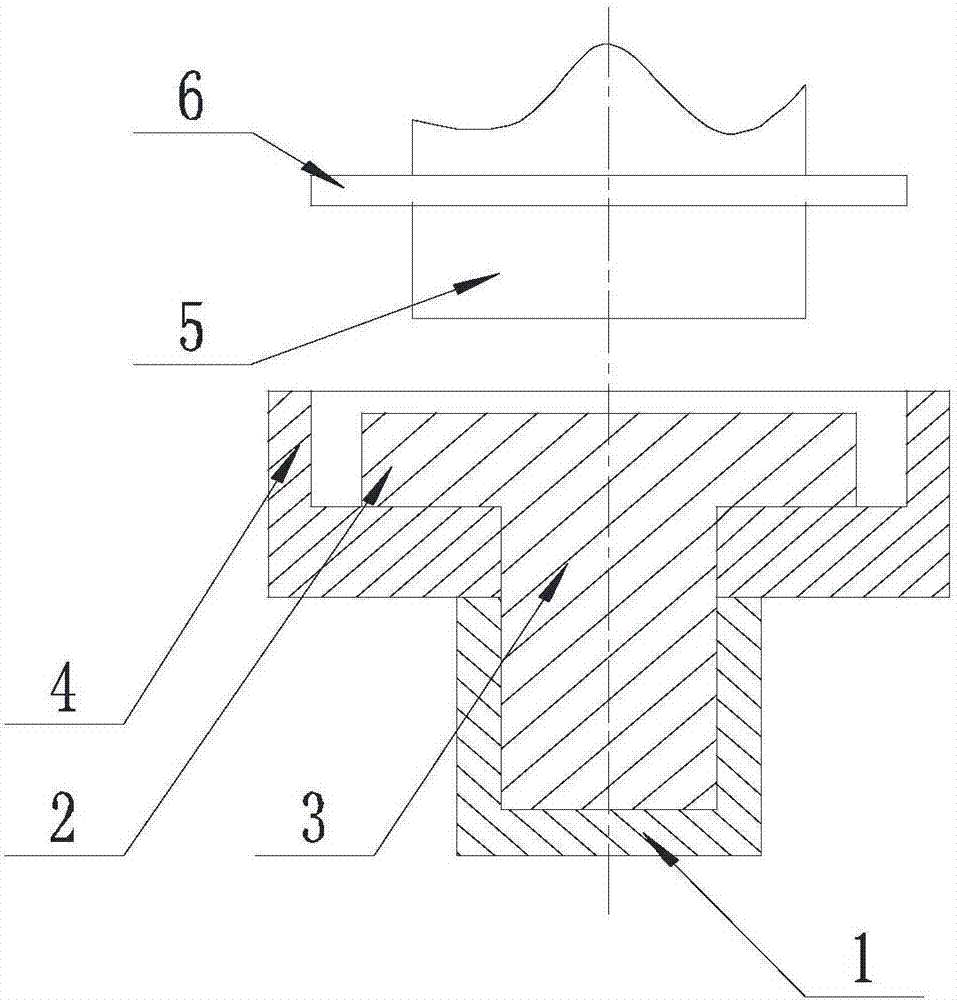

[0031] Such as Figure 1-Figure 2 Shown, a kind of processing method of hexagon socket head bolt of the present invention, comprises the steps:

[0032] Step A preparation: heat and melt the raw material of the bolt, and then perform blanking, forging, and annealing in sequence to form a blank rod of equal diameter;

[0033] Step B piering: Use a pier roughing machine to partially pier the blank rod, so that the diameter of one end of the blank rod is greater than the initial diameter of the blank rod, so that the original blank rod becomes the original rod and the thick rod that are sequentially connected and coaxial;

[0034] Step C hot extrusion: Extrude the thick rod through the hot extrusion machine, the hot extruder clamps the original rod, and heats the thick rod, and places the thick rod in the die 4, and the original rod is drawn from the die 4 The upper end away from the punch 5 passes through, and is located in the dimension-shaped sleeve 1 whose central hole size ...

Embodiment 2

[0039] The present invention is based on embodiment 1, and the present invention is further described.

[0040] Such as Figure 1-Figure 2 As shown, a processing method of a hexagon socket head bolt of the present invention, the die 4 is provided with an extrusion hole 2, and the bottom of the extrusion hole 2 is provided with a relief hole 3, and the diameter of the relief hole 3 is Consistent with the rod diameter of the original rod, the dimension-shaped sleeve 1 is arranged on the die 4 at an end away from the punch 5, and the axis of the dimension-shaped sleeve 1 is coaxial with the relief hole 2;

[0041] Further, a pressing plate 6 is sheathed on the punch 5 , the cross section of the pressing plate 6 is circular, and its diameter is consistent with that of the extrusion hole 2 . The pressing plate 6 presses the thick rod away from the end of the bottom of the extrusion hole 2 on the thick rod to prevent the thick rod from protruding and deforming to the punch 5 during...

Embodiment 3

[0044] The present invention is based on embodiment 1, and the present invention is further described.

[0045] Such as Figure 1-Figure 2 Shown, the present invention a kind of processing method of hexagon socket head cap bolt, described step B comprises step B ' initial pier and step B " pier again, described step B ' initial pier: thicken the diameter pier of thick bar to the diameter of rough bar 1.2-1.5 times;

[0046] Said step B" pier again: pier the diameter of the thick rod to 2-3 times of the diameter of the rough rod.

[0047] Further, in the step C, the heating temperature of the thick rod is 800-850°C, and there is also a step C' between the step C and the step D, and the step C' is softened and annealed: the hot-extruded column Body undergoes softening annealing treatment.

[0048] The softening annealing treatment is as follows: heating first, heating the column body to 650-700°C, and the heating time is 2-3 hours; Cooling, cooling the column to 300-400 °C a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com