Printing head modular design based on 3D printer

A modular design, 3D printer technology, applied in the field of 3D printing, can solve the problems of automatic leveling module can not miniaturize space utilization, lack of integrated design for remote wire feeding, limit printing speed, etc., to protect and block lines , reduce weight and prevent heat from moving up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

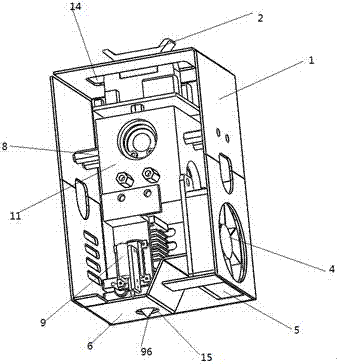

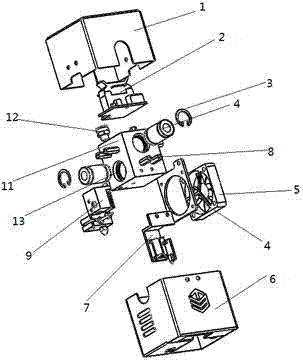

[0024] Such as figure 1 with figure 2 As shown, a modular design of a printing head based on a 3D printer includes an upper protective cover 1 and a lower protective cover 6, a moving block 11 is installed between the upper protective cover 1 and the lower protective cover 2, and the upper protective cover 1 and the lower protective cover The cover 6 is fixed on the moving block 11 through the hexagonal copper column 8, the upper end of the moving block 11 is equipped with a terminal block 2 and a quick-plug connector 12, the left end of the moving block 11 is equipped with an extruding module 9, and the right end of the moving block 11 is installed with a cooling fan 4, The cooling fan 4 is installed on the movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com