Self-overflow type graphene oily sewage treatment device

A treatment device, graphene technology, applied in natural water treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc., to achieve high oil removal efficiency, wide requirements for influent water quality, and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

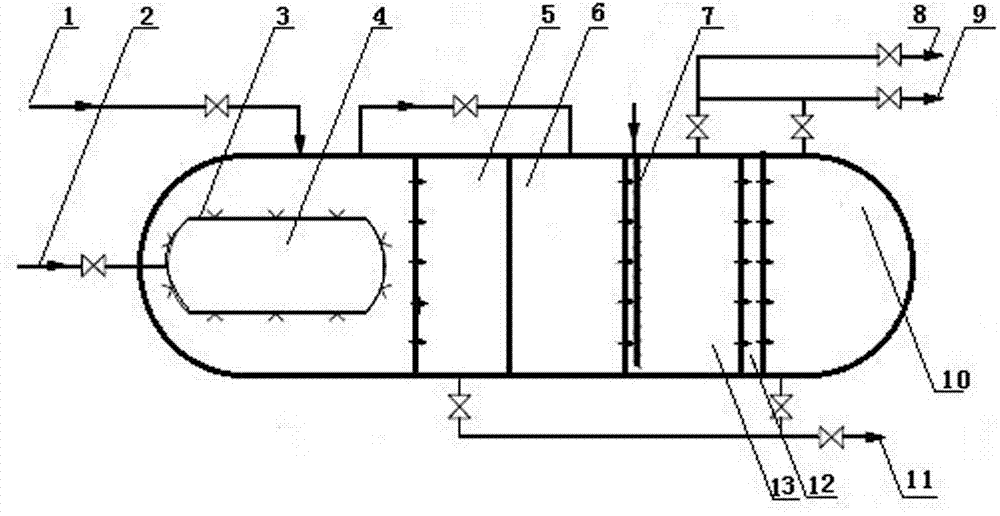

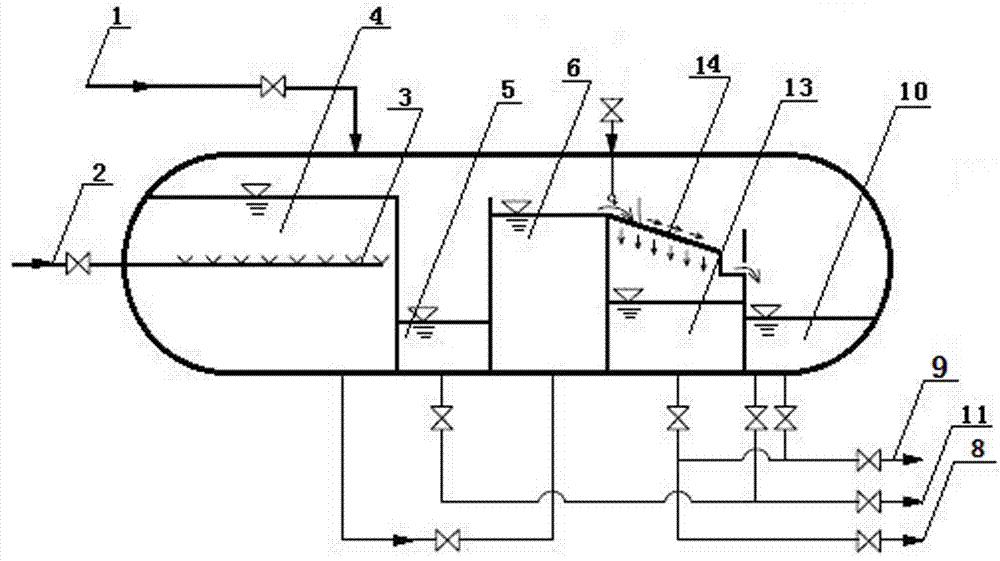

[0019] Self-overflow type graphene oily sewage treatment device, including tank body, water distribution pipe, graphene-based mesh 14, water pipeline and oil pipeline, the tank body is a horizontal cylindrical sealed container, and there is a gas connection port on the top, which is the nitrogen inlet 1; The oil-water separation chamber 4, the oil collection chamber, the sewage chamber 6, and the water production chamber 13 are sequentially arranged in the tank; the oily sewage inlet 2 is connected to the oil-water separation chamber 4, and the upper part of the oil-water separation chamber 4 is surrounded by a water distribution pipe A3, There are multiple water spray pipes evenly distributed on the water distribution pipe A3, and the nozzles of the water spray pipes are upward; the right side of the oil-water separation chamber 4 is the first-stage oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com