Forced overflow type graphene oil-containing sewage treatment device

A treatment device, graphene technology, applied in water/sludge/sewage treatment, multi-stage water treatment, mining wastewater treatment, etc., to achieve the effects of high oil removal efficiency, wide water quality requirements and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

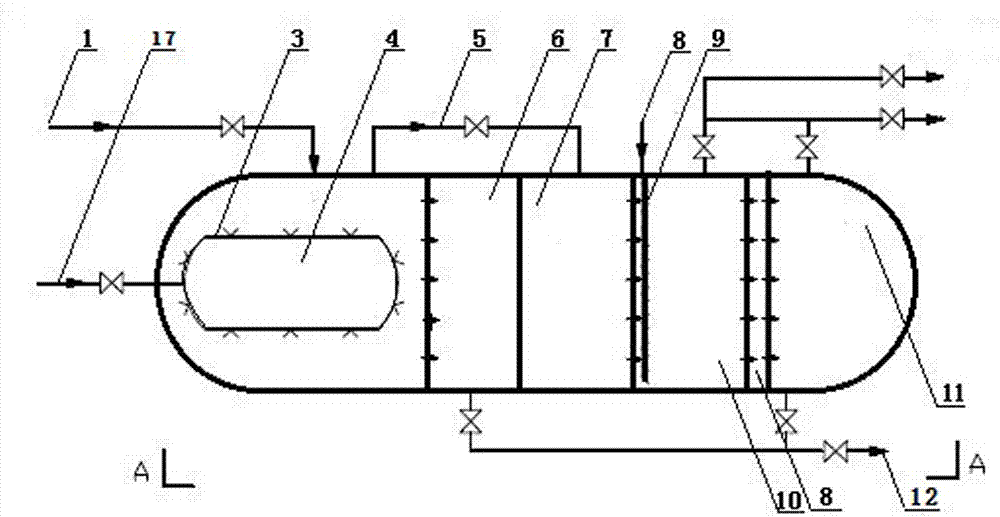

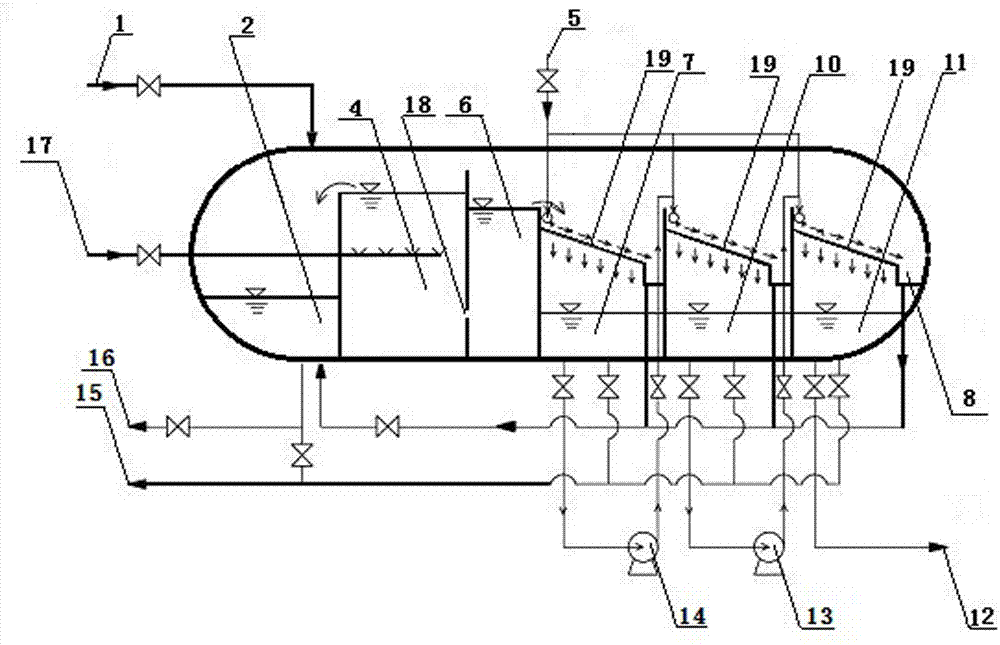

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] Forced overflow graphene oily sewage treatment device, including tank body, flushing water inlet 5, primary water production chamber 7, secondary water production chamber 10, third stage water production chamber 11, water distribution pipe, primary overflow pump 14 , secondary overflow pump 13, graphene-based omentum 19, water pipeline and oil pipeline, the tank body is a horizontal cylindrical airtight container with a gas connection port on the top, which is a nitrogen inlet 1; Chamber 2, oil-water separation chamber 4, water production chamber and oil collection tank 8; wherein the oily sewage inlet 17 is connected with the oil-water separation chamber 4, and the upper part of the oil-water separation chamber 4 is surrounded by a water distribution pipe A3, and a plurality of spray nozzles are evenly distributed on the water distribution pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com