A heat treatment method for improving the mechanical properties of austenitic heat-resistant steel

A technology of austenitic heat-resistant steel and heat treatment method, which is applied in the field of heat treatment, can solve problems such as limited improvement of mechanical properties, and achieve the effect of performance optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

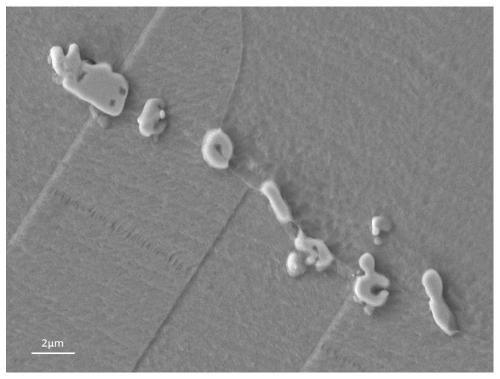

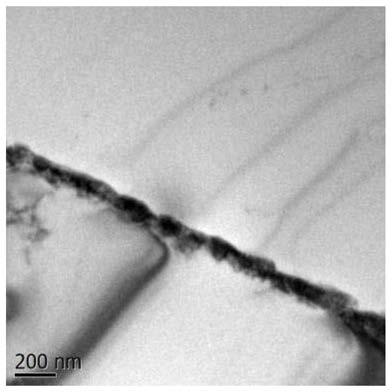

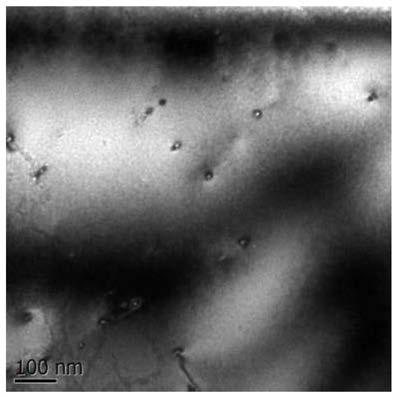

[0025] The invention discloses a heat treatment method for improving the mechanical properties of austenitic heat-resistant steel, which uses a solution treatment process combined with a medium-temperature short-term aging treatment to precipitate fine M 23 C 6 phase and nano-sized Z phase (NbCrN phase) to optimize the performance of heat-resistant steel. The comparison between the chemical composition of the austenitic heat-resistant steel obtained in this example and the existing HR3C steel is shown in Table 1.

[0026] Table 1 Chemical composition (mass %, balance is Fe) of austenitic heat-resistant steel (1#) and comparative example (HR3C steel) used in Example 1.

[0027]

[0028] The present invention is a heat treatment method for improving the mechanical properties of austenitic heat-resistant steel, the steps are as follows:

[0029] 1. Heat the alloy sample that has been homogenized and thermally deformed in sequence to 1230°C, keep it warm for 30 minutes for so...

example 2

[0040] A heat treatment method for improving the mechanical properties of austenitic heat-resistant steel, comprising the steps of,

[0041] Step 1. Raw materials are prepared according to the alloy composition and burning loss, and the raw materials are melted and cast into alloy ingots in a vacuum environment;

[0042] Step 2, the alloy ingot is subjected to homogenization and thermal deformation treatment in sequence;

[0043] Step 3, performing solution heat treatment on the hot-deformed alloy at 1200°C for 45 minutes, and then water-cooling to room temperature;

[0044] Step 4, short-term aging treatment at medium temperature: heat the alloy after solution heat treatment to 800°C, hold it for 30 minutes, and cool it to room temperature in air. get M 23 C 6 Mutually.

[0045] In this preferred example, the alloy ingot is homogenized at 1150° C. for 30 hours. The homogenized alloy ingot is subjected to heat deformation treatment at 1150°C.

example 3

[0047] A heat treatment method for improving the mechanical properties of austenitic heat-resistant steel, comprising the steps of,

[0048] Step 1. Raw materials are prepared according to the alloy composition and burning loss, and the raw materials are melted and cast into alloy ingots in a vacuum environment;

[0049] Step 2, the alloy ingot is subjected to homogenization and thermal deformation treatment in sequence;

[0050] Step 3, performing solution heat treatment on the hot-deformed alloy at 1260° C. for 35 minutes, and then water-cooling to room temperature;

[0051] Step 4, short-term aging treatment at medium temperature: heat the alloy after solution heat treatment to 760°C, hold it for 40 minutes, and cool it to room temperature in air. get M 23 C 6 Mutually.

[0052] In this preferred example, the alloy ingot is homogenized at 1200° C. for 20 hours. The homogenized alloy ingot is subjected to heat deformation treatment at 1150°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com