Monitoring rod

A pole and body technology, applied in the field of monitoring poles, can solve the problems of waste of cost, time-consuming and laborious, etc., and achieve the effects of convenient use, convenient manual installation and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

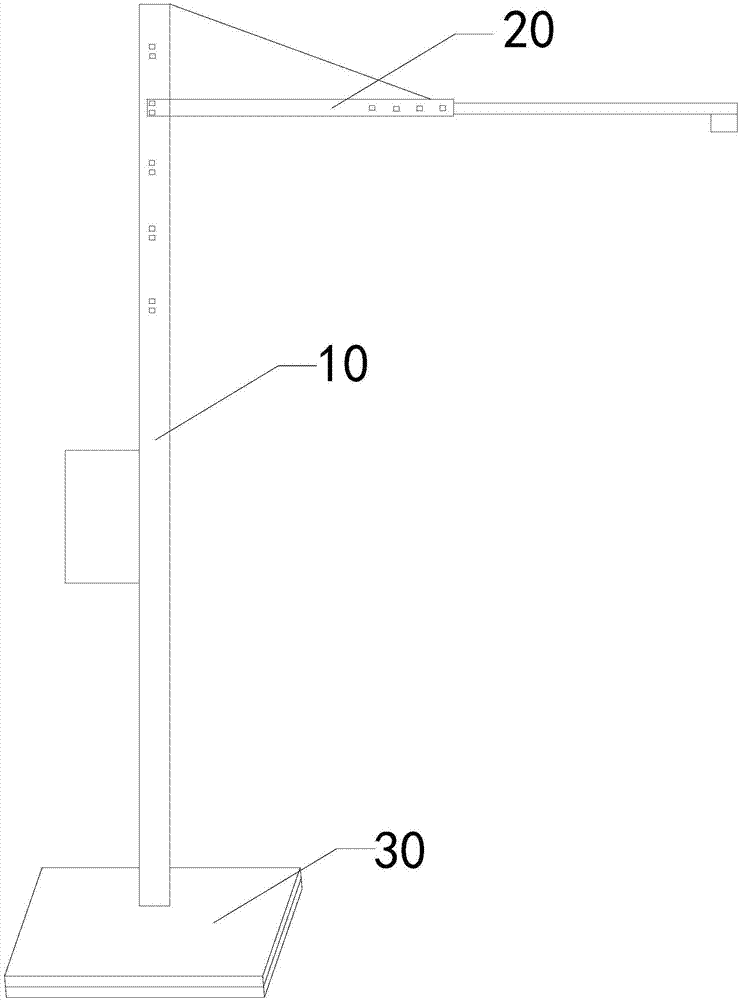

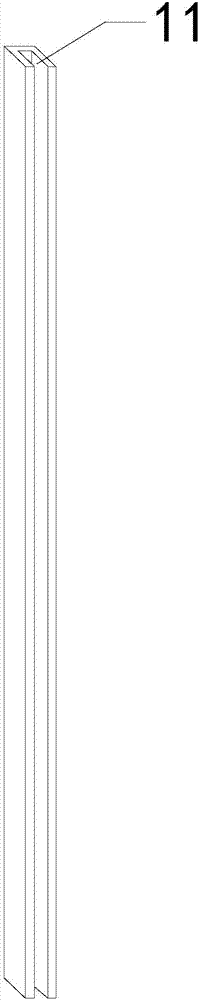

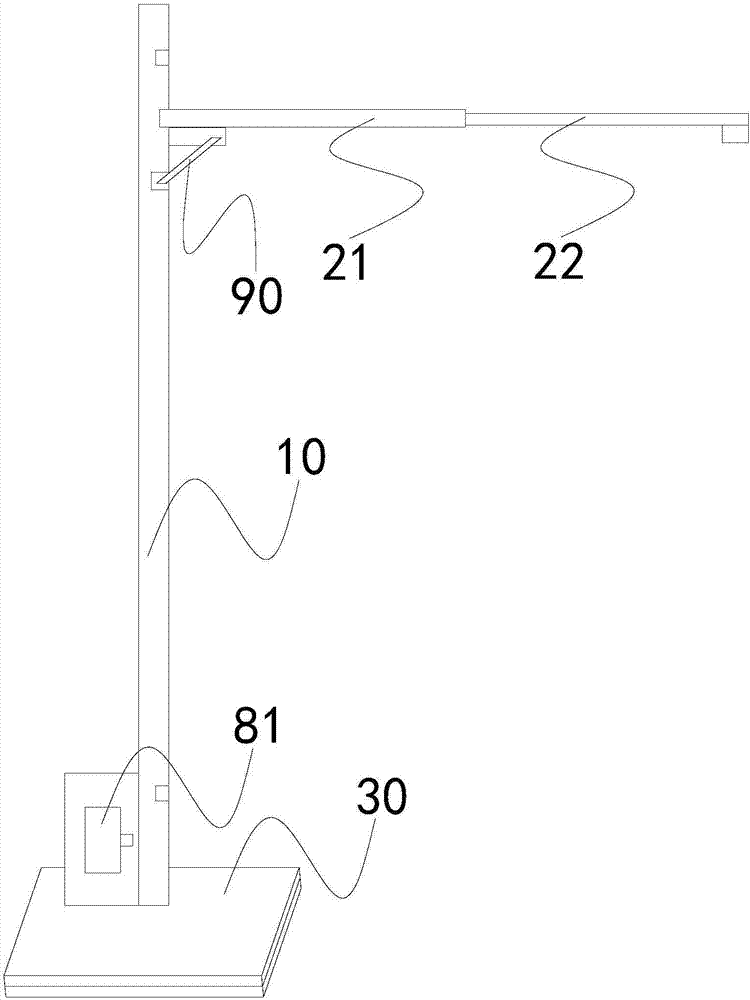

[0044] see figure 1 , figure 2 , image 3 as well as Figure 4 , a monitoring pole of the present invention, comprising a pole body 10, a bracket 20, and a movable base 30, the pole body is arranged on the movable base, the cross section of the pole body is a groove structure 11, and a first gear 40 is also included , the second gear 50, the chain 60, the lifting plate 70 and the power unit, the first gear and the second gear are arranged on the same side of the pole body, and the first gear is arranged directly above the second gear, and the chain It is an endless chain, one side of the chain is arranged in the groove structure of the pole body, the chain is meshed with the first gear and the second gear respectively, the power device includes a first motor 81, and the first motor and the second gear transmission connection; one end of the bracket is fixed on the lifting plate. The first motor is provided with a box to cover the entire first motor, the first motor drives...

Embodiment 2

[0049] In this embodiment, on the basis of Embodiment 1, the single-side vertical rod body is changed into a double-sided vertical rod body, such as Figure 5 As shown, the monitoring rod includes two vertical rod bodies, two lifting plates and two supports; the two sides of the chain are respectively arranged in the groove structures of the two vertical rod bodies, and the two lifting plates 70 are respectively fixed on the sides of the chain. On both sides, one end of the two brackets is respectively fixed on the two lifting plates. Since the chain is on both sides, the left side goes up, the right side goes down; the left side goes down, the right side goes up; therefore, this principle can be used to place two pole bodies, and two sets of monitoring systems can be used at the same time, or an accident can occur in another monitoring system When using another monitoring system, the two systems are connected in series and do not affect each other. The use is more intelligent...

Embodiment 3

[0051] In this embodiment, on the basis of Embodiment 2, the bracket is improved. The bracket includes a front bracket 21, a rear bracket 22, a third gear 23, and a rack 24. The cross section of the front bracket is a groove structure. One end of the front bracket is fixed on the lifting plate, the other end of the front bracket is sleeved on the rear bracket, the rack is arranged in the groove structure of the front bracket, and one end of the rack is fixedly connected with the rear bracket. The third gear meshes with the rack, and the power device further includes a second motor, which is in drive connection with the third gear. In this way, by controlling the forward and reverse rotation of the second motor, the extension and retraction of the rear bracket can be controlled, and there is no need to remove the front and rear brackets to modify the monitoring distance, which saves time and effort, and is more in line with the needs of modern automation.

[0052]During use, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com