Variables speis pump system for closed hydraulic circuits

A feeding pump, hydrostatic technology, applied in the direction of components with teeth, transmission, transmission control, etc., to achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

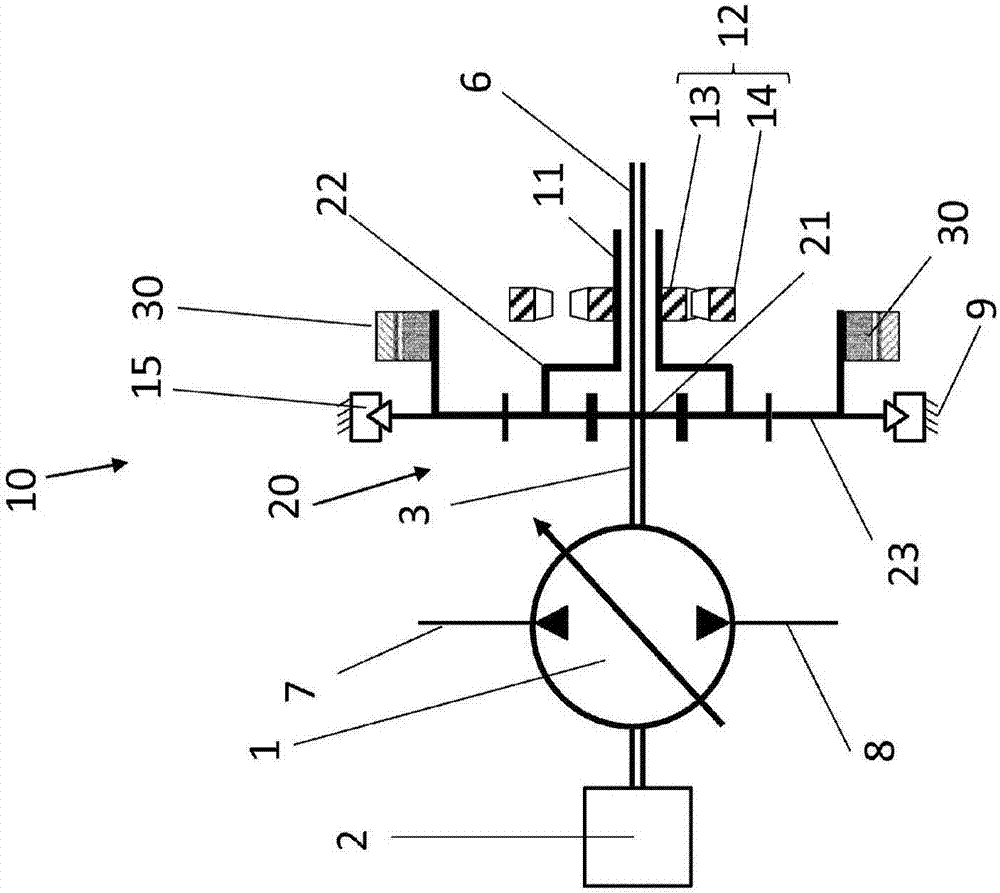

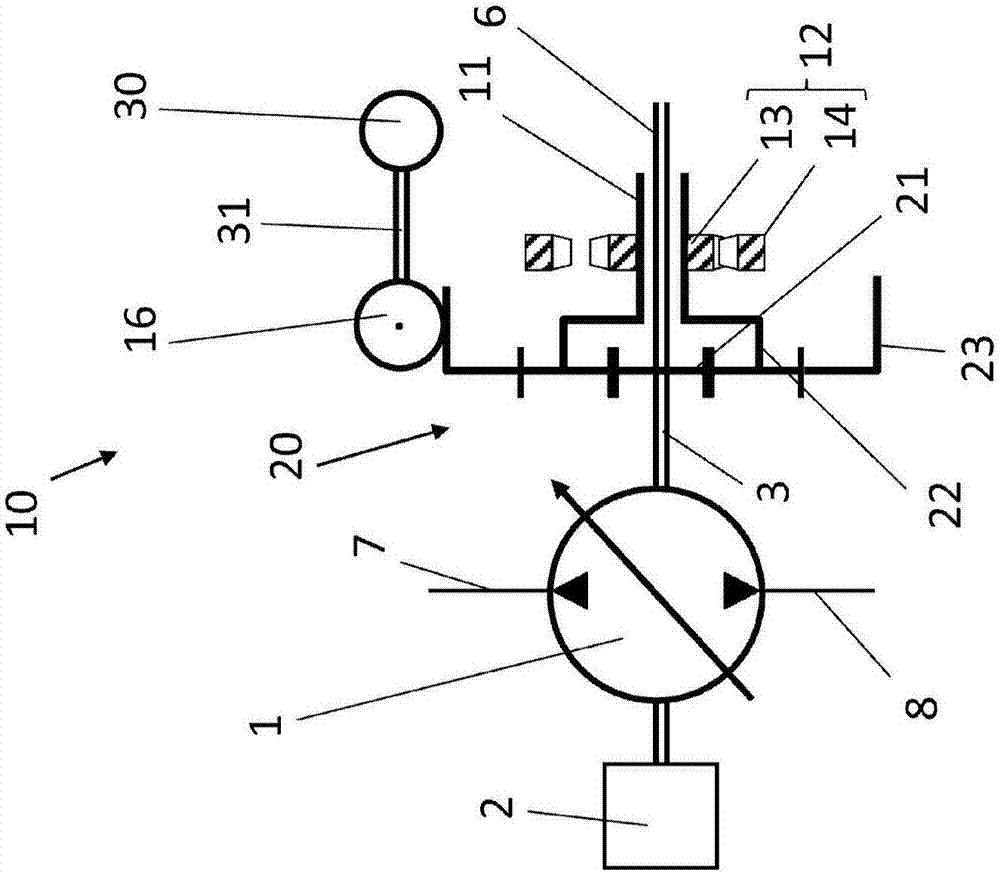

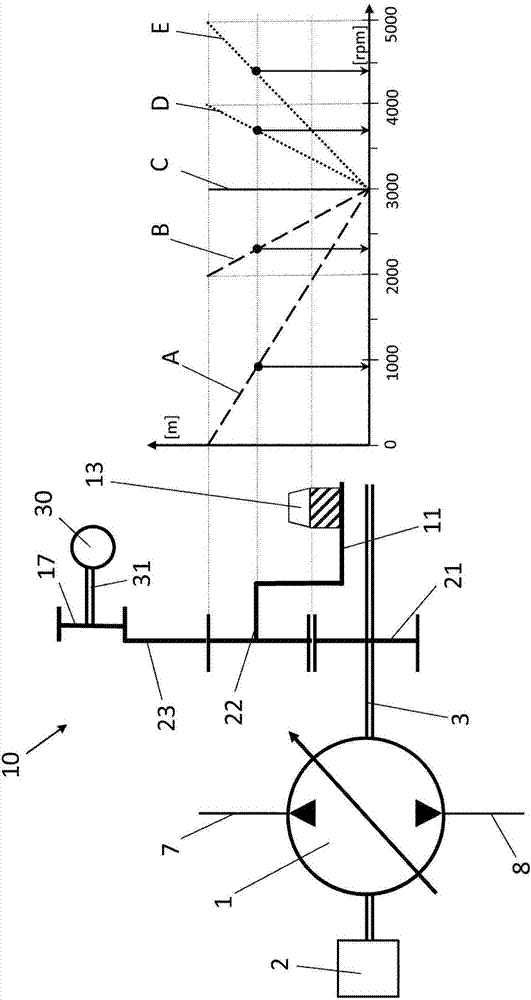

[0024] in figure 1 Here, a first embodiment of the charging pump system 10 of the present invention coupled or connected to the hydrostatic main pump 1 is shown in a schematic manner. The hydrostatic pump 1 is driven by a rotary drive device 2 such as a combustion-type drive engine. In this embodiment, the hydrostatic pump 1 is a variable displacement type, however, it may be a constant or fixed displacement pump type. Hydrostatic pump 1 uses working lines 7 and 8 in Figure 1 to Figure 3 The closed hydrostatic circuit shown transports hydraulic fluid. The drive shaft 3 of the main pump 1 connected to the rotation drive device 2 drives the sun gear 21 of the planetary gear set 20. The planet carrier 22 of the planetary gear set 20 is designed to be used as the rotational input power of the charging pump 12. in Figure 1 to Figure 3 In the illustrated embodiment, the internal gear 13 of the feeding pump 12 is driven by the input shaft 11, and the input shaft 11 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com