RKS-rotary furnace and grate furnace incineration system

A rotary kiln and material storage tank technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of inhomogeneity, unsatisfactory combustion effect, not easy to burn out, etc., and achieve resource saving and simple structure , easy-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

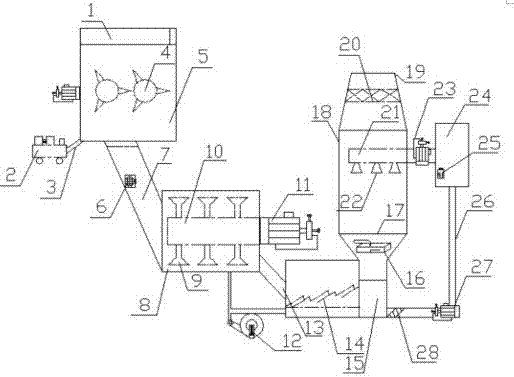

[0015] Such as figure 1 The RKS-rotary grate furnace incineration system includes a cover plate 1, an air pump 2, a ventilation pipe 3, a double-toothed roller 4, a storage tank 5, a dryer 6, a feeding pipeline 7, a rotary furnace 8, a scraper Plate 9, rotating shaft 10, motor 11, fan 12, feeding pipe 13, grate furnace 14, slag storage tank 15, burner 16, secondary combustion chamber 17, flue gas cooling chamber 18, flue gas outlet 19, activated carbon adsorption layer 20. Water spray pipeline 21, conical nozzle 22, water pump 23, water tank 24, refrigerator 25, circulation pipeline 26, circulation pump 27, filter screen 28, storage tank 5 and storage tank 5 are arranged on the left side of rotary kiln 8 The rotary furnace 8 is connected through the feeding pipeline 7, the cover plate 1 is set on the upper end of the storage tank 5, the double-toothed roller 4 is set in the storage tank 5, and the air pump 2 is arranged outside the storage tank 5, and the air pump 2 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com