Tapered optical fiber based high-power optical fiber end cap

A tapered fiber and fiber end technology, applied in the field of fiber lasers, can solve the problems of lowering the threshold of nonlinear effects and increasing the interaction distance of nonlinear effects, so as to improve the cooling effect, reduce the back light feedback, and improve the safety. and the effect of workplace stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

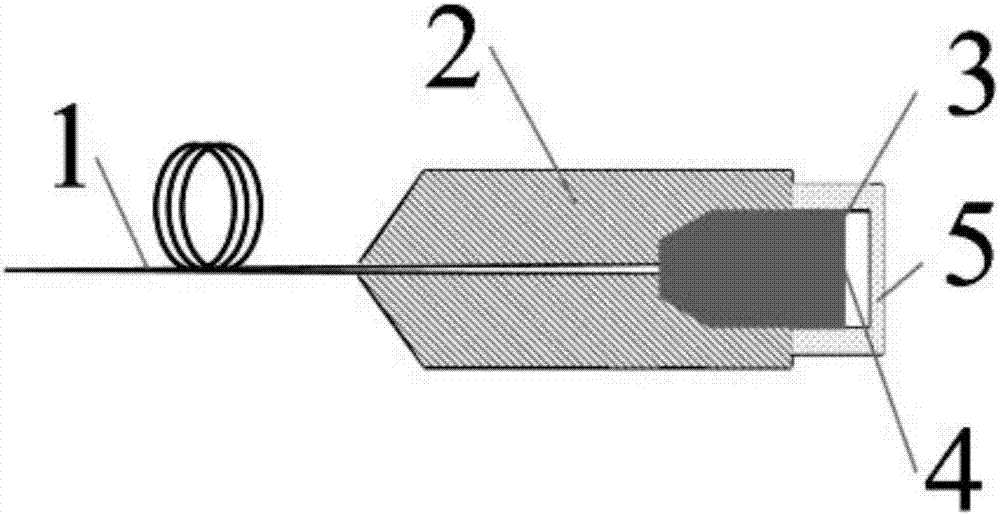

[0033] Example 1: See figure 1 , a high-power fiber end cap based on a single-clad tapered optical fiber, comprising a single-clad tapered optical fiber 1, a quartz block 3 and an end cap shell 2, the large end of the single-clad tapered optical fiber 1 from the end cap shell 2 One end penetrates into the inside of the end cap shell 2 and is fixed on the end cap shell 2. The other end of the end cap shell 2 is provided with a cavity for the quartz block 3 to extend into. The quartz block 3 extends into the inside of the end cap shell. One end is a truncated conical end, the end of the quartz block 3 extending out of the end cap shell 2 is cylindrical and the end surface of the cylindrical end of the quartz block 3 extending out of the end cap shell 2 is coated with an anti-reflection film 4; on the end cap Inside the shell 2, the frustum-shaped end of the quartz block 3 is fused with the large end of the tapered optical fiber 1, and an output end cap protection window is set ...

Embodiment 2

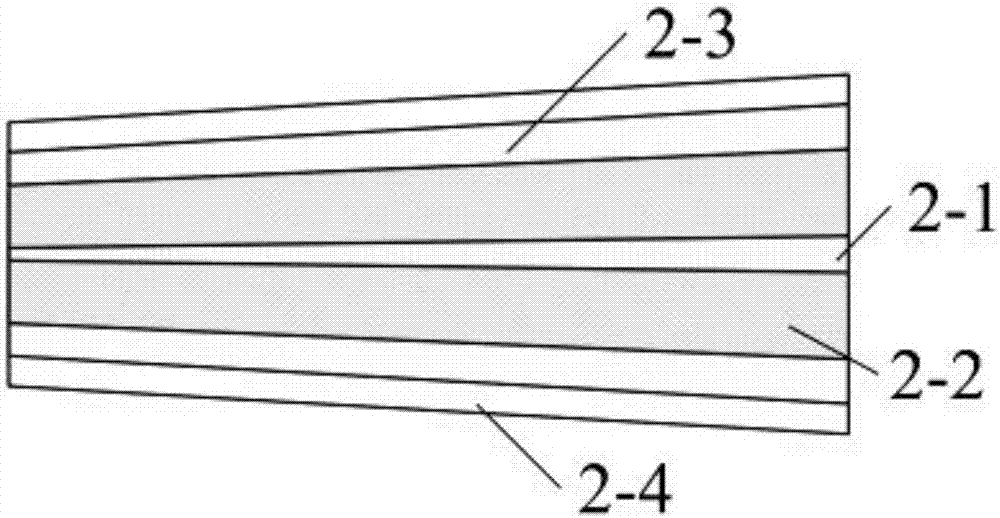

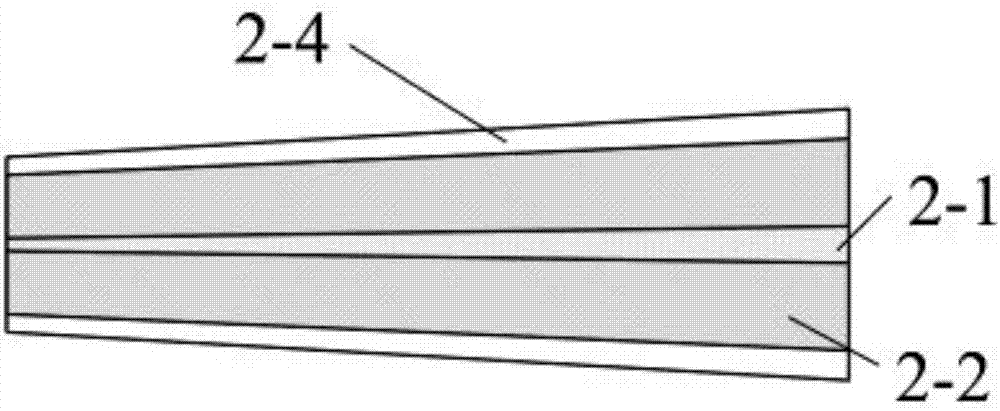

[0036] Example 2: see Figure 6 , a schematic diagram of a high-power fiber end-cap structure based on a double-clad tapered fiber. For the double-clad tapered optical fiber 6, one end of the double-clad tapered optical fiber 6 inserted into the end cap shell 2 needs to remove its coating 2-4 before stretching into the end cap shell 2 inside, that is, stretch into the end cap The double-clad tapered optical fiber 6 inside the housing 2 is a section of optical fiber 7 with the coating removed. The surface of the optical fiber 7 from which the coating layer has been removed is coated and cured with an ultraviolet curing adhesive 8 to form a cladding optical stripper.

[0037] Flowing cooling liquid is arranged inside the end cap housing 2 to assist heat dissipation. In this embodiment, the inside of the end cap housing 2 is a cavity 11 . The large end of the processed double-clad tapered optical fiber 6 is penetrated from one end of the end cap shell 2 into the inner cavity o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com