Sea sedge automatic dewatering forming machine

An automatic molding machine and seaweed technology, applied in food science and other directions, can solve the problems of low production efficiency, difficult to guarantee sanitary conditions, large manual labor, etc., and achieve the effect of reducing labor costs, safe and hygienic production process, and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is described in detail.

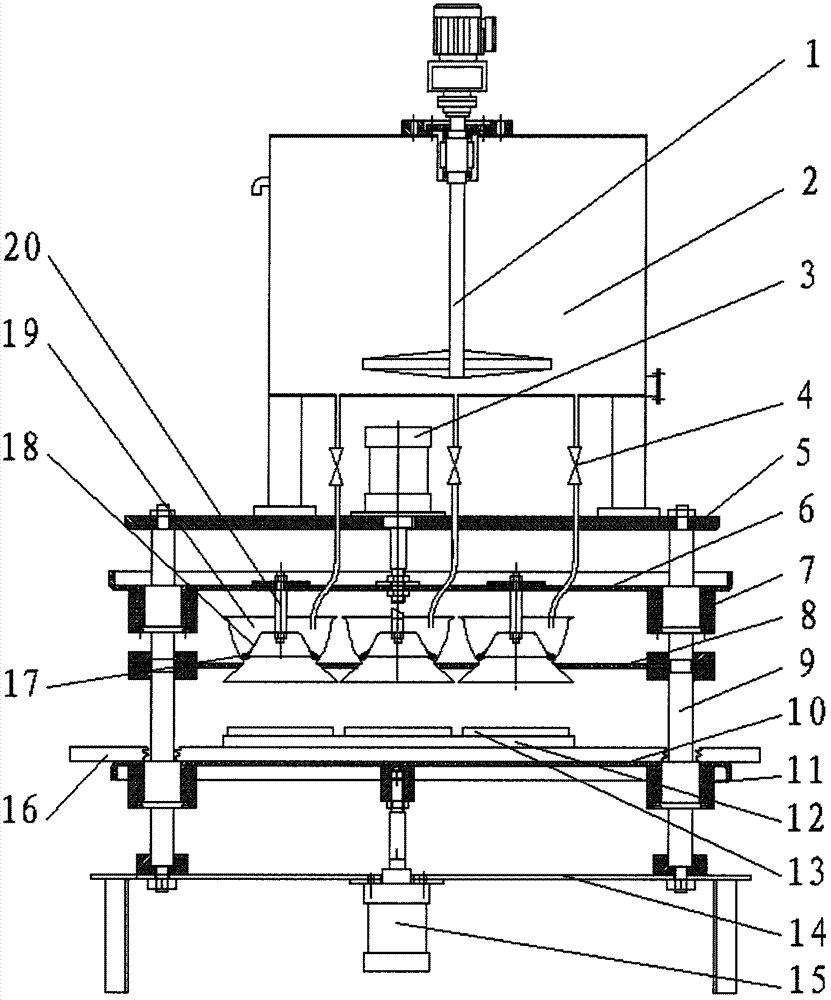

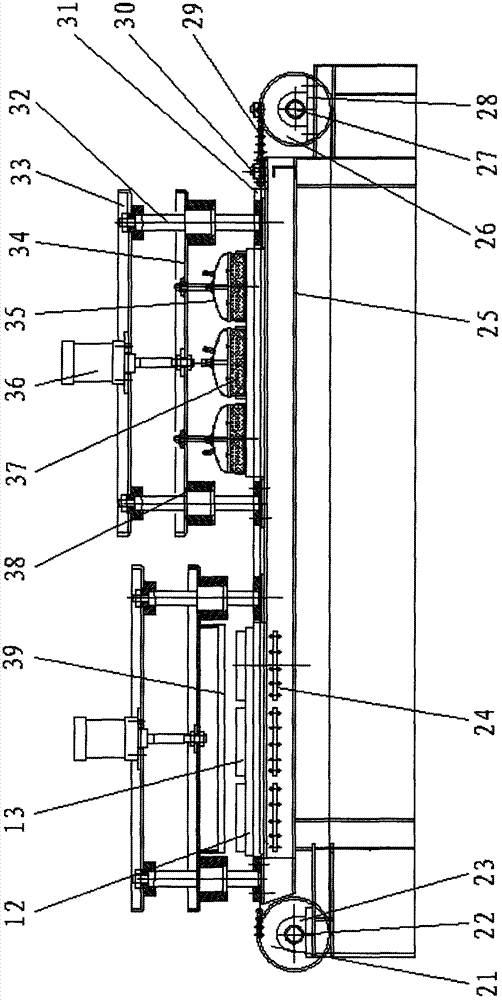

[0020] The seaweed dehydration forming machine is composed of forming part, extrusion part and air blowing part sequentially connected. The upper surface of the guide rail of the forming part is on the same plane as the top surface of the chain in the extrusion part and air blowing part, which can realize the pouring and forming of seaweed cake in sequence , extrusion dehydration, blowing fluffy and other processes, the working cycle of each process is the same.

[0021] The forming part consists of base 14, water tray cylinder 15, large column 9, water tray 10, distributor 19, upper tray 6, cover plate 5, feeding cylinder 3, valve 4, feeding barrel 2, agitator 1 and other main parts. Components are composed, and the relationship between each component is: from the forming part to the blowing part, the water pan cylinder 15 with the piston rod upward is fixed at the center of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com