A composite material with electrocatalytic carbon dioxide reduction performance, preparation method and application thereof

A carbon composite material, carbon dioxide technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., can solve the problems of expensive raw materials, low Faradaic efficiency, high overpotential, and achieve low cost, high mechanical strength, phase Good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

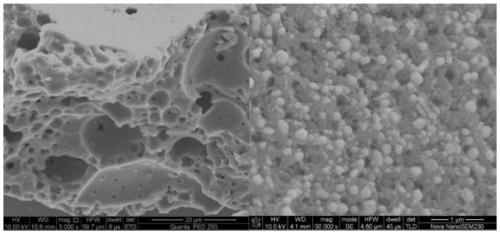

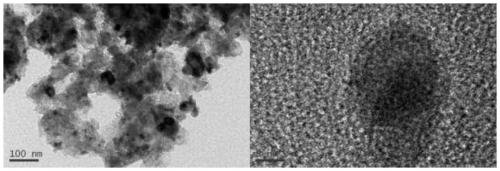

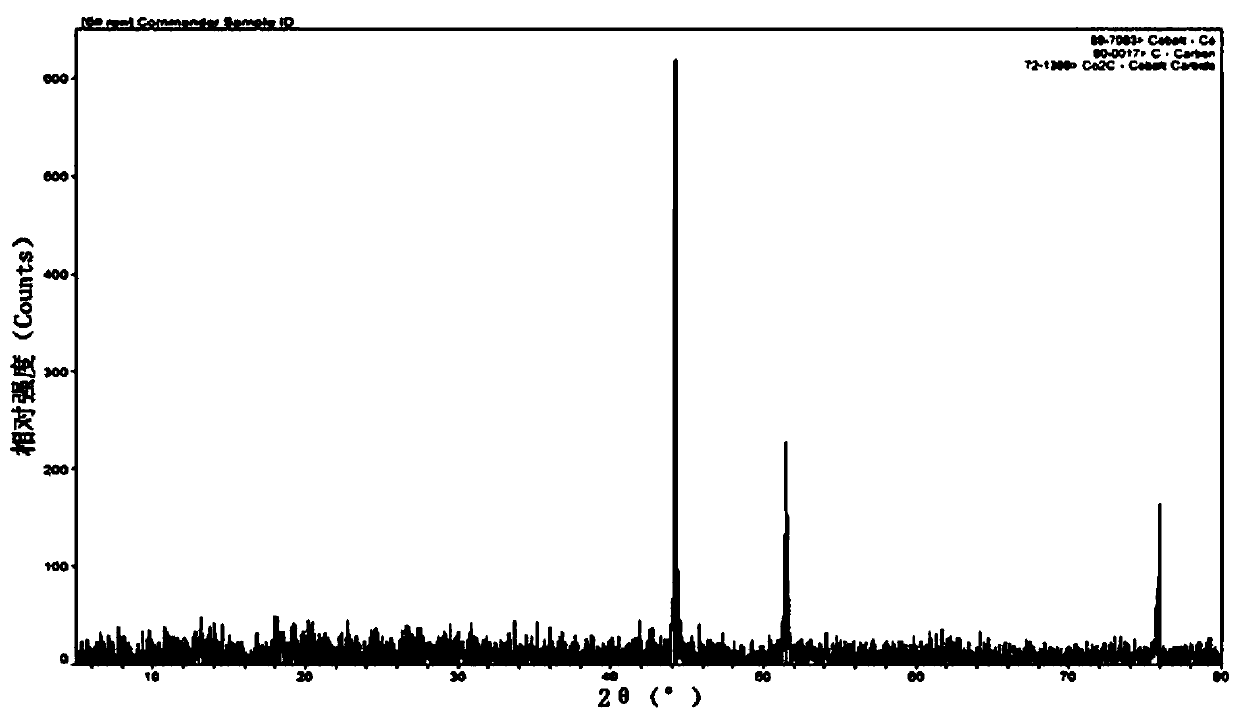

[0040] A cobalt-carbon composite material of the present invention, the cobalt-carbon composite material has a three-dimensional network structure. Humic acid-phenolic resin foam is used as a three-dimensional porous carbon support, and cobalt ions are adsorbed on the three-dimensional porous carbon support, and then Co-C active catalytic sites are formed by high-temperature heat treatment in a reducing atmosphere.

[0041] The preparation method of this cobalt-carbon composite material is as follows:

[0042] (1) Preparation of phenolic resin foam

[0043] With phenol, 37% formaldehyde aqueous solution and humic acid as raw material, be 20% sodium hydroxide aqueous solution as catalyst with mass fraction, add phenol in the four-necked flask that agitator, reflux condenser and thermometer are housed (heating and melting in advance ), humic acid and 37% formaldehyde aqueous solution, add sodium hydroxide aqueous solution under stirring, heat up to 90 ° C, react for 2-3 hours, ...

Embodiment 2

[0060] A cobalt-carbon-oxygen composite material of the present invention, the cobalt-carbon-oxygen composite material has a three-dimensional network structure. Using humic acid-phenolic resin foam as a three-dimensional porous carbon support, cobalt ions are adsorbed on the three-dimensional porous carbon support, and then the Co-C active catalytic center is formed by high-temperature heat treatment in a reducing atmosphere, and then reacted with oxygen at high temperature to incorporate oxygen. atoms, forming Co-C-O active catalytic sites.

[0061] The preparation method of the cobalt-carbon-oxygen composite material is as follows:

[0062] (1) Preparation of phenolic resin foam

[0063] With phenol, 37% formaldehyde aqueous solution and humic acid as raw material, be that 20% sodium hydroxide aqueous solution is made catalyst with mass fraction, add phenol in the four-necked flask that stirrer, reflux condenser and thermometer are housed (heating and melting in advance )...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com