Loaded nano silicon carbide nickel-based catalyst, and preparation method thereof

A technology of nano-silicon carbide and nickel-based catalysts, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve the problems of low catalytic activity, easy deactivation, poor hydrogen selectivity, etc., and achieve catalytic High activity, low production cost, and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

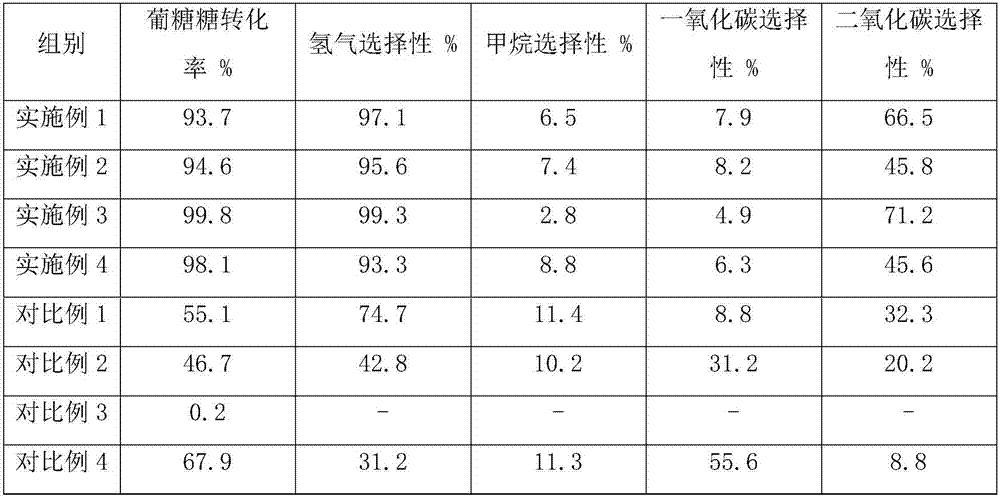

Examples

Embodiment 1

[0037] A preparation method of a nickel-based catalyst supported by nano-silicon carbide, comprising the following steps:

[0038] Raw material composition (molar ratio)

[0039] Nano silicon carbide: 10 parts; copper acetylacetonate: 1 part; 1-hexadecane mercaptan: 2 parts; nickel chloride: 2 parts; ammonia water: 6 parts; cerium sulfate: 1 part.

[0040] Step 1, adding the nano-silicon carbide to 1000 times the weight of pure water, ultrasonically dispersing, adding the 1-hexadecanethiol, and ultrasonicating for 20 minutes;

[0041] Step 2, the mixed solution obtained in step 1 is added to the copper acetylacetonate under a nitrogen atmosphere and vigorously stirred, and reacted at 80° C. for 3-4 hours;

[0042] Step 3, transfer the solution obtained in Step 2 into a microwave hydrothermal kettle, and react at 220-250°C for 20-40 minutes under a nitrogen atmosphere; after cooling, centrifuge and wash;

[0043] Step 4, ultrasonically disperse the solid obtained in Step 3 in...

Embodiment 2

[0046] A preparation method of a nickel-based catalyst supported by nano-silicon carbide, comprising the following steps:

[0047] Raw material composition (molar ratio)

[0048] Nano silicon carbide: 11 parts; copper acetylacetonate: 1 part; 1-hexadecane mercaptan: 2 parts; nickel sulfate: 4 parts; ammonia water: 8 parts; cerium sulfate: 1 part.

[0049] Step 1, adding the nano-silicon carbide to 1000 times the weight of pure water, ultrasonically dispersing, adding the 1-hexadecanethiol, and ultrasonicating for 20 minutes;

[0050] Step 2, the mixed solution obtained in step 1 is added to the copper acetylacetonate under a nitrogen atmosphere and vigorously stirred, and reacted at 80° C. for 3-4 hours;

[0051] Step 3, transfer the solution obtained in Step 2 into a microwave hydrothermal kettle, and react at 220-250°C for 20-40 minutes under a nitrogen atmosphere; after cooling, centrifuge and wash;

[0052] Step 4: Ultrasonically disperse the solid obtained in Step 3 in ...

Embodiment 3

[0055] A preparation method of a nickel-based catalyst supported by nano-silicon carbide, comprising the following steps:

[0056] Raw material composition (molar ratio)

[0057] Nano silicon carbide: 11 parts; copper acetylacetonate: 3 parts; 1-hexadecane mercaptan: 6 parts; nickel chloride: 6 parts; ammonia water: 10 parts; cerium sulfate: 1 part.

[0058] Step 1, adding the nano-silicon carbide to 1000 times the weight of pure water, ultrasonically dispersing, adding the 1-hexadecanethiol, and ultrasonicating for 20 minutes;

[0059] Step 2, the mixed solution obtained in step 1 is added to the copper acetylacetonate under a nitrogen atmosphere and vigorously stirred, and reacted at 80° C. for 3-4 hours;

[0060] Step 3, transfer the solution obtained in Step 2 into a microwave hydrothermal kettle, and react at 220-250°C for 20-40 minutes under a nitrogen atmosphere; after cooling, centrifuge and wash;

[0061] Step 4: Ultrasonically disperse the solid obtained in Step 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com