Open type 3D printer based on cold printing

A 3D printer and 3D printing technology, applied in 3D object support structures, processing platforms/substrates, additive manufacturing, etc., can solve the problem that material costs and structural stability cannot increase synchronously, damage the gap between printing nozzles and printing platforms, and affect model printing Quality and other issues, to achieve the effect of facilitating promotion and application, improving installation accuracy and space utilization, and stabilizing the leveling and printing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

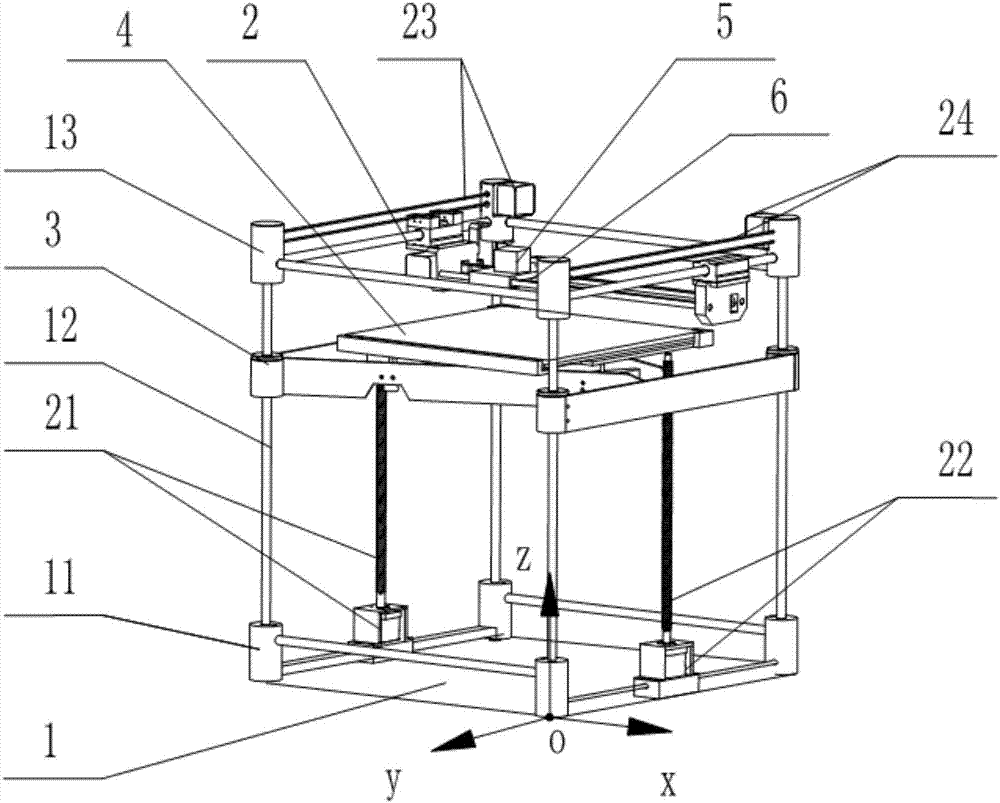

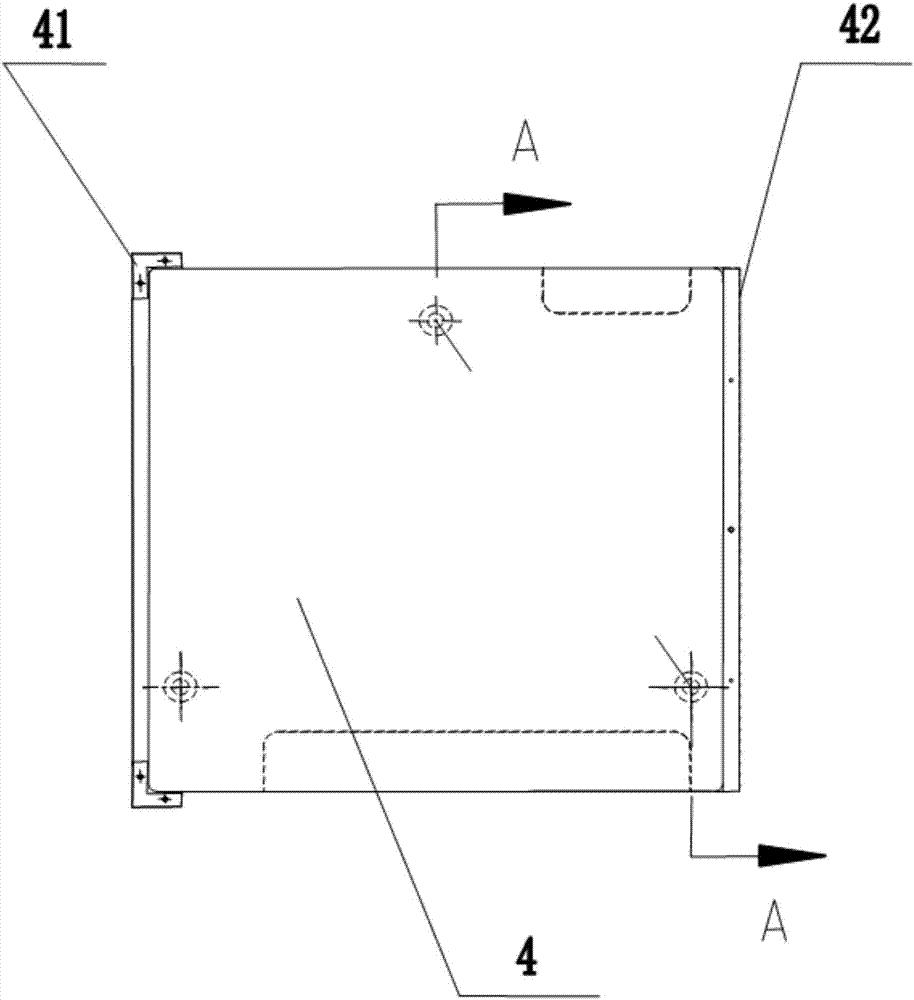

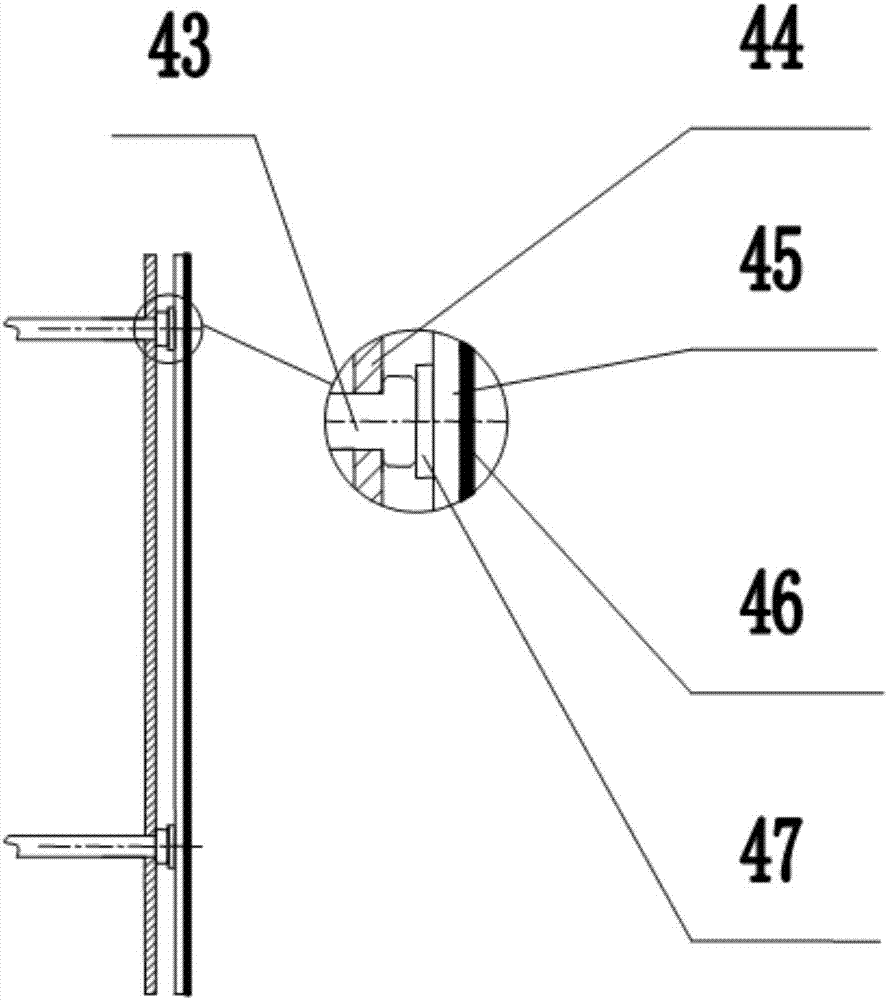

[0025] Such as figure 1 As shown, an open 3D printer based on cold printing adopts the basic principles and working parts of 3D printers. On the basis of analyzing the problems existing in existing hot bed heating 3D printers, some structures and systems are redesigned and innovated. , including frame 1, transmission system 2 and printing platform 4.

[0026] Most of the existing hot bed heating 3D printers are made of sheet metal structures or spliced PVC panels, resulting in high manufacturing costs or poor physical structure stability. In view of this, the cold printing open 3D printer developed by the present invention adopts a skeleton structure design for its frame 1 . It is mainly composed of bottom positioning angle code 11, optical axis 12 and top positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com