Breathable wood-plastic plate production technology

A production process, wood-plastic board technology, applied in other home appliances, home appliances, applications, etc., can solve problems such as lengthy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

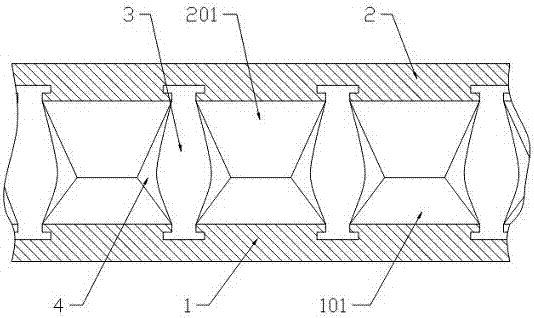

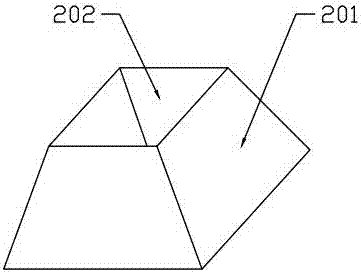

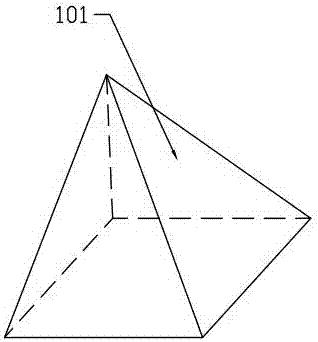

[0030] Such as Figure 1-Figure 4 As shown, the adhesive and plant fiber are mixed into a primary material, and the primary material is heated to 180°C; the heated primary material is processed into a flat substrate by extrusion, molding, injection molding and other plastic processing techniques. The thickness of the substrate is 8mm. One side of the substrate is a plane, and a solid wood board with a thickness of 2mm is glued on the plane. There are several square installation grooves with a depth of 4mm in a rectangular array on the other side of the substrate. The distance between adjacent installation grooves on the substrate is 4mm, every four adjacent installation grooves are formed with a depth of 4mm slots; take the heated primary material to make the fixed column 3, the alignment column 101 and the platform column 201, and the two ends of the fixed column 3 are formed There is a rib 301 matched with the card slot, the alignment column 101 is conical, the cap column 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com