Method for preparing non-fired ceramsite from electroplating sludge

A technology for electroplating sludge and ceramsite, which is applied in the field of environmental protection and achieves a good reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the examples given by the inventor.

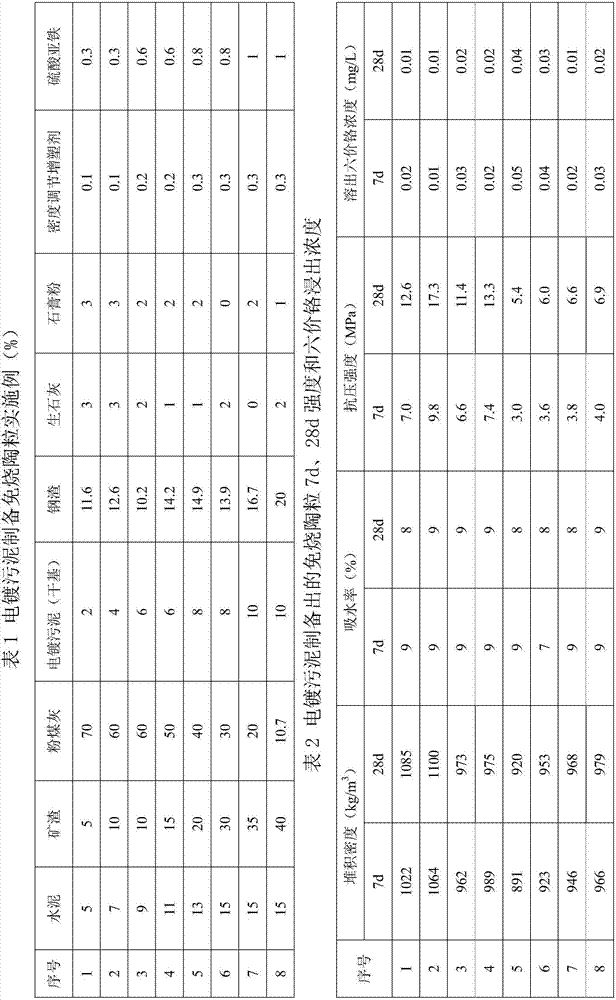

[0013] Table 1 is the constituent raw materials and their weight percentages of 8 embodiments of the present invention. The raw materials are all in powder form except electroplating sludge, which should be fully mixed in advance. After mixing evenly, add the original electroplating sludge and an appropriate amount of water to forcefully roll and stir until uniform, and then put the mixed mud into the granulator Granulation, natural maintenance after granulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com