Preparation process of perphenazine

A technology of preparation process and process steps, which is applied in the field of preparation of antipsychotic drugs, can solve the problems of low yield, and achieve the effects of high quality, complete reaction and high solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2

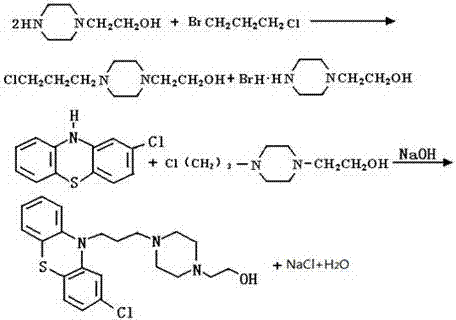

[0037] The preparation technology of embodiment 1,2 and comparative example 1,2

[0038] 1) Synthesis of side chains: Put the mixed solvent / toluene and N-(2-hydroxyethyl)piperazine into the reaction kettle in turn and heat up to 70°C and stir evenly; then cool down to 38°C, add 1,3-bromo Chloropropane reacted for 3.7 hours, cooled and centrifuged to shake off the material;

[0039] 2) Condensation: Put the mixed solvent / toluene, 2-chlorophenothiazine, and sodium hydroxide into the reaction kettle and reflux and dehydrate at 120°C for 3.5 hours; use chloropropyl N-(2-hydroxyethyl)piperazine Add chloropropyl N-(2-hydroxyethyl)piperazine in the form of benzene solution, separate the generated water through the water separator during the dropwise addition, and reflux for 4.5 hours; after cooling to below 100°C, add water and stir Static layering, the alkali water layer is separated to obtain the condensation product;

[0040] 3) Crude product: the condensation product is washed ...

Embodiment 5

[0047] The preparation technology of embodiment 5,6

[0048] 1) Synthesis of side chains: Put the mixed solvent and N-(2-hydroxyethyl)piperazine into the reaction kettle in turn and heat up to 74°C and stir evenly; then cool down to 40°C, add 1,3-bromochloropropane dropwise React for 3.7 hours, cool down, and centrifuge to shake off the material;

[0049] 2) Condensation: Put the mixed solvent, 2-chlorophenothiazine, and sodium hydroxide into the reaction kettle and reflux and dehydrate at 118°C for 4 hours; Add chloropropyl N-(2-hydroxyethyl)piperazine in the form of the solution, separate the generated water through the water separator during the dropwise addition, and reflux for 4 hours; cool down to below 100°C, add water and stir, and then separate Layer, the alkali water layer is separated to obtain the condensation product;

[0050] 3) Crude product: the condensation product is washed successively by adding water, standing for stratification, dividing the water layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com