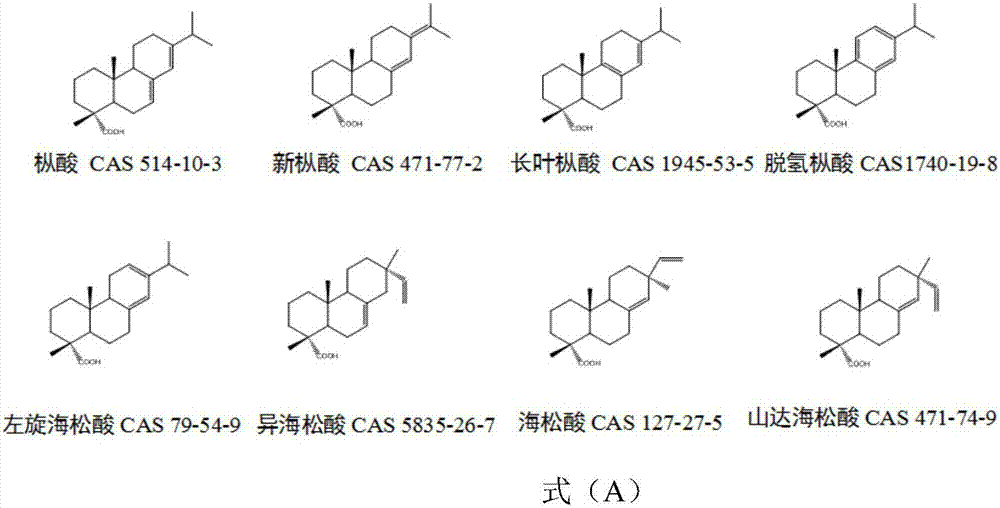

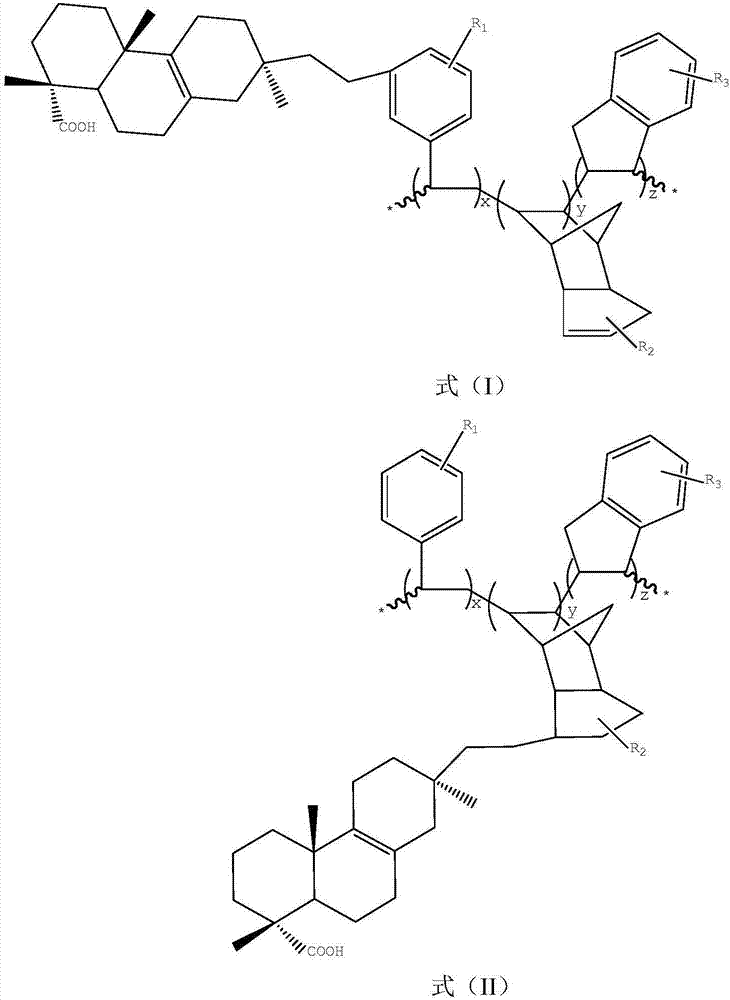

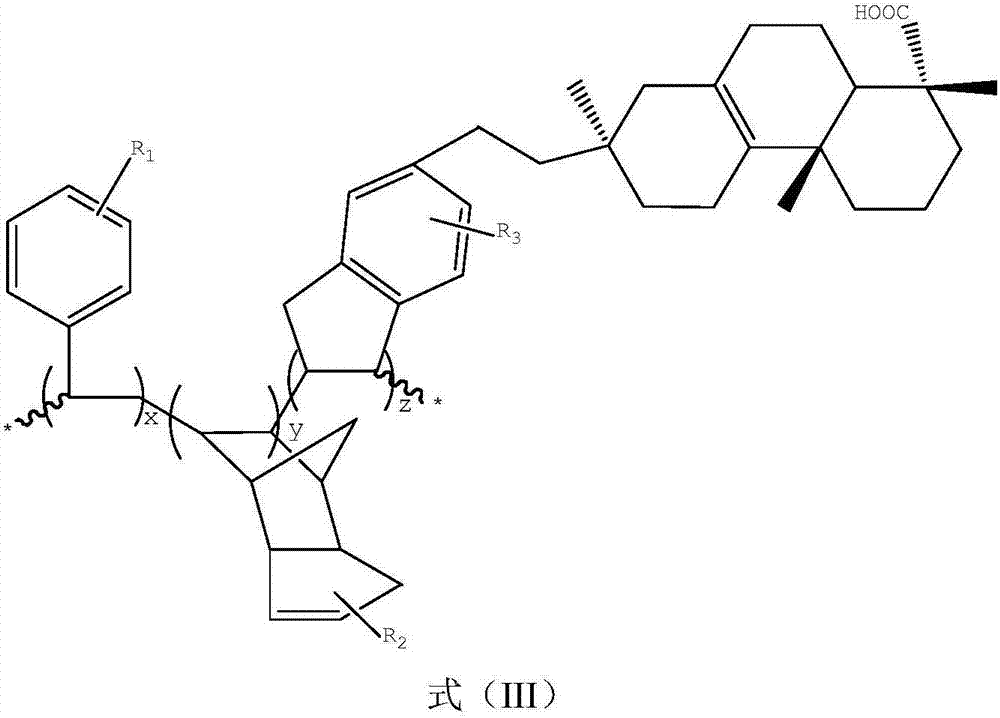

Rosin modified C9 petroleum resin, preparation method and application thereof

A rosin modification, petroleum resin technology, applied in transportation and packaging, tire parts, rolling resistance optimization, etc., can solve problems such as performance index decline, improve wet grip, high yield, and improve tear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Put 70 parts of raw material styrene, 30 parts of toluene and 50 parts of rosin with an iodine value of 183 into the autoclave. 1.1MPa. After reacting for 3 hours, the temperature was lowered to below 100°C, the reactant was poured out, and excess solvent and unreacted monomer were evaporated to obtain 108 parts of yellow resin with a softening point of 108°C.

Embodiment 2

[0052] Raw materials and solvent ratios are the same as in Example 1. Raise the reaction temperature to 200°C. After the temperature stabilizes, the pressure is at 0.3MPa. After 4 hours of reaction, the temperature is lowered to below 100°C. The reacted monomers gave 96 parts of a yellow resin having a softening point of 103°C.

Embodiment 3

[0054] The ratio of raw materials and solvents is the same as in Example 1. Raise the reaction temperature to 300°C. After the temperature stabilizes, the pressure stabilizes at 2.6MPa. After 2 hours of reaction, lower the temperature to below 100°C, pour out the reactants, and steam out excess The solvent and unreacted monomers were used to obtain 110 parts of yellow resin having a softening point of 110°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com