Rotor engine

A rotor and engine technology, applied in the sealing device of the engine, combustion engine, machine/engine, etc., can solve the problems of difficult engine maintenance, increased fuel consumption and pollution, air leakage, etc., to ensure the sealing effect, wear degree and wear speed. The effect of reducing and improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

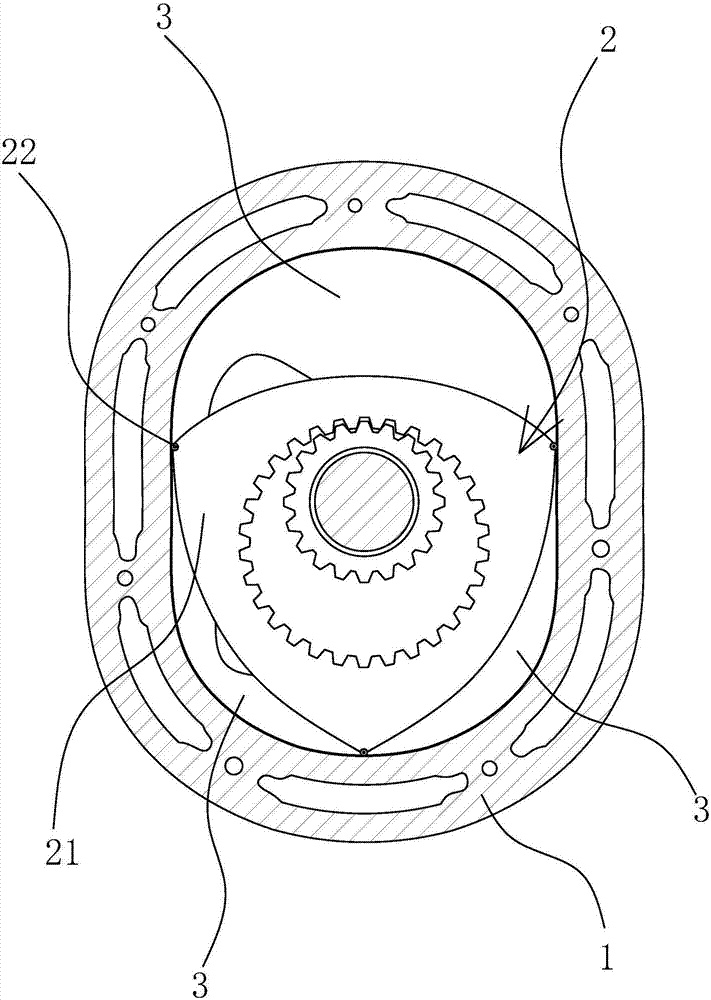

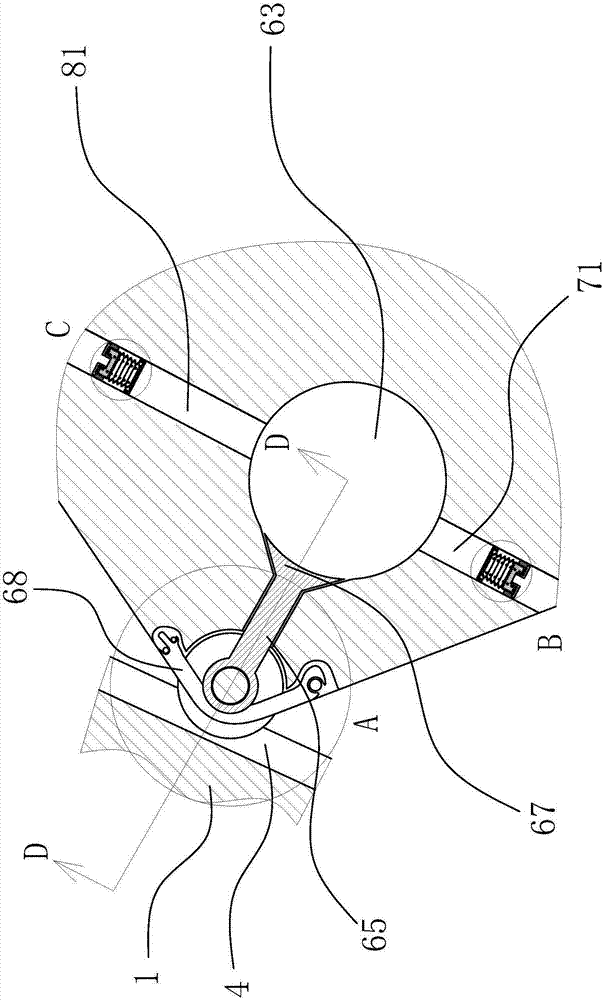

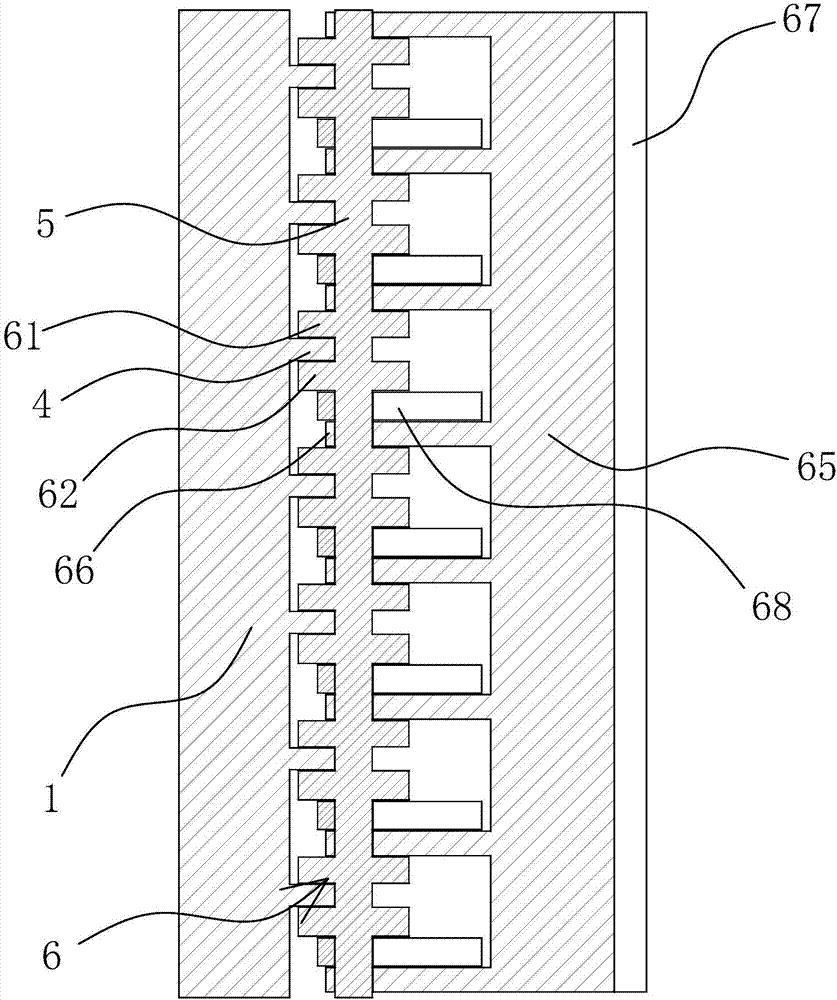

[0027] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the rotary engine includes a cylinder 1 and a rotor 2 located in the cylinder 1. The rotor 2 divides the cylinder 1 into three combustion chambers 3. The rotor 2 includes a body 21 and seals respectively located at three corners of the body 21. part 22, several sealing steel rings 4 are arranged on the inner wall of the cylinder body 1, and the rotating column 5 which can rotate freely is arranged at the sealing part 22, and the sealing assembly 6 corresponding to the sealing steel rings 4 is arranged on the rotating column 5 , the sealing assembly 6 includes clip one 61 and clip two 62 fixedly arranged on the rotating column 5, the clip one 61 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com