Stove head used for soup rice cooking

A claypot rice and burner technology, which is applied in the field of gas stoves, can solve the problems of uneven heating effect of claypot and burnt residue on the surface of the heated vessel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

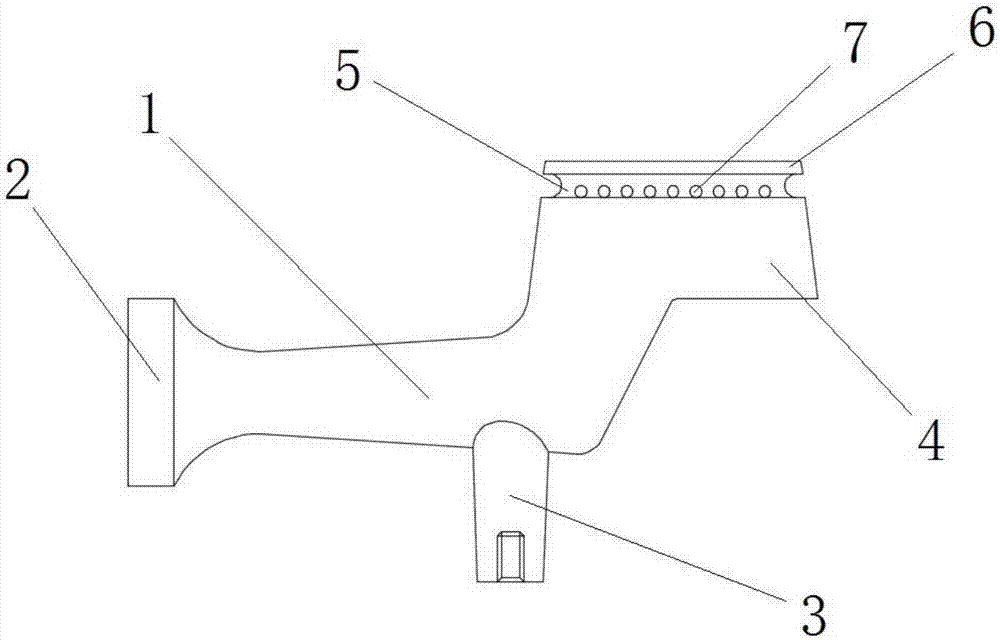

[0020] A burner for cooking claypot rice, comprising an air pipe 1, an end 2, a support rod 3, a base 4, a plate surface 5, a fire cover 6, and a through hole 7, wherein the end 2 is located at one end of the air pipe 1 , the other end of the air pipe 1 is fixedly connected to the base 4, the support rod 3 is fixedly connected to the lower end of the air pipe 1, the disk surface 5 is fixedly connected to the top of the base 4, the fire cover 6 is located on the top of the disk surface 5, and the disk surface 5 A number of through holes 7 are opened on the top, and there is a gas channel in the gas delivery pipe 1. One end of the gas channel extends to the end 2, and the other end is divided into several branches to communicate with the plurality of through holes 7 respectively. A gas filter element is fixedly connected.

Embodiment 2

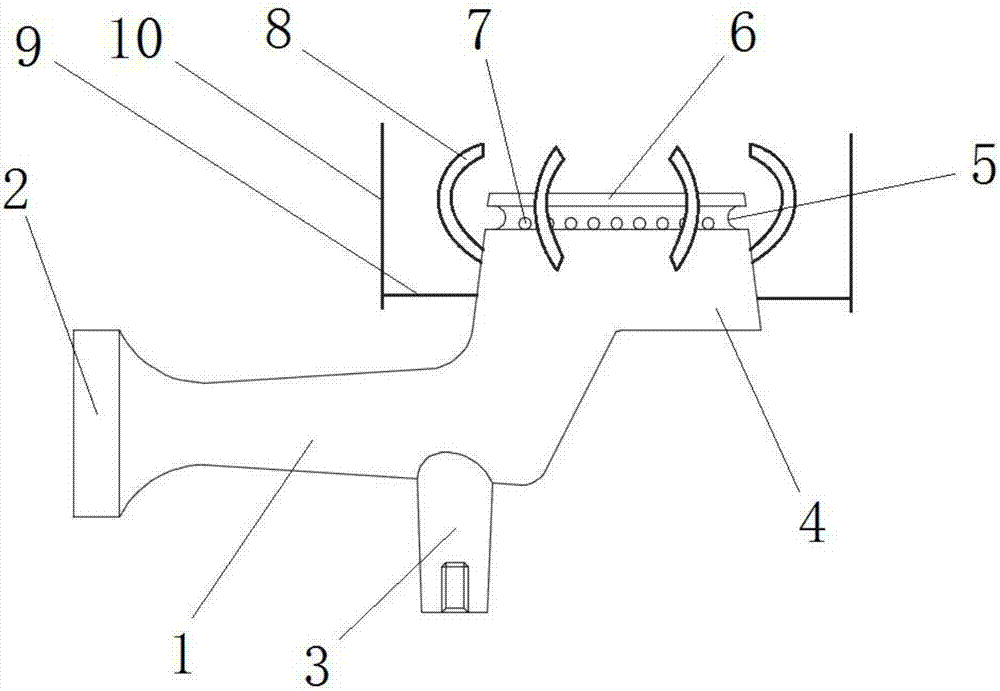

[0022] A burner for cooking claypot rice, comprising an air pipe 1, a terminal 2, a support rod 3, a base 4, a plate surface 5, a fire cover 6, and a through hole 7, wherein the end 2 is located at one end of the air pipe 1 , the other end of the air pipe 1 is fixedly connected to the base 4, the support rod 3 is fixedly connected to the lower end of the air pipe 1, the disk surface 5 is fixedly connected to the top of the base 4, the fire cover 6 is located on the top of the disk surface 5, and the disk surface 5 A number of through holes 7 are opened on the top, and there is a gas channel in the gas delivery pipe 1. One end of the gas channel extends to the end 2, and the other end is divided into several branches to communicate with the plurality of through holes 7 respectively. A gas filter element is fixedly connected.

[0023] On the basis of the above technical solutions, the following conditions are met:

[0024] It also includes an arc tube 8 fixedly connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com