Semiconductor film laminating machine

A semiconductor and laminating machine technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, etc., can solve problems such as error-prone, increased labor costs, loss, etc., to improve efficiency and reduce labor Cost, the effect of realizing the film sticking operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further described in conjunction with the following examples.

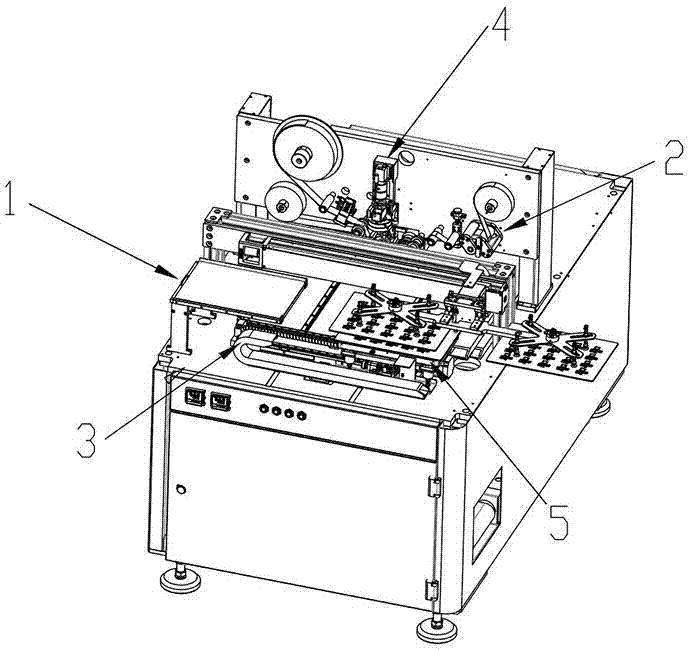

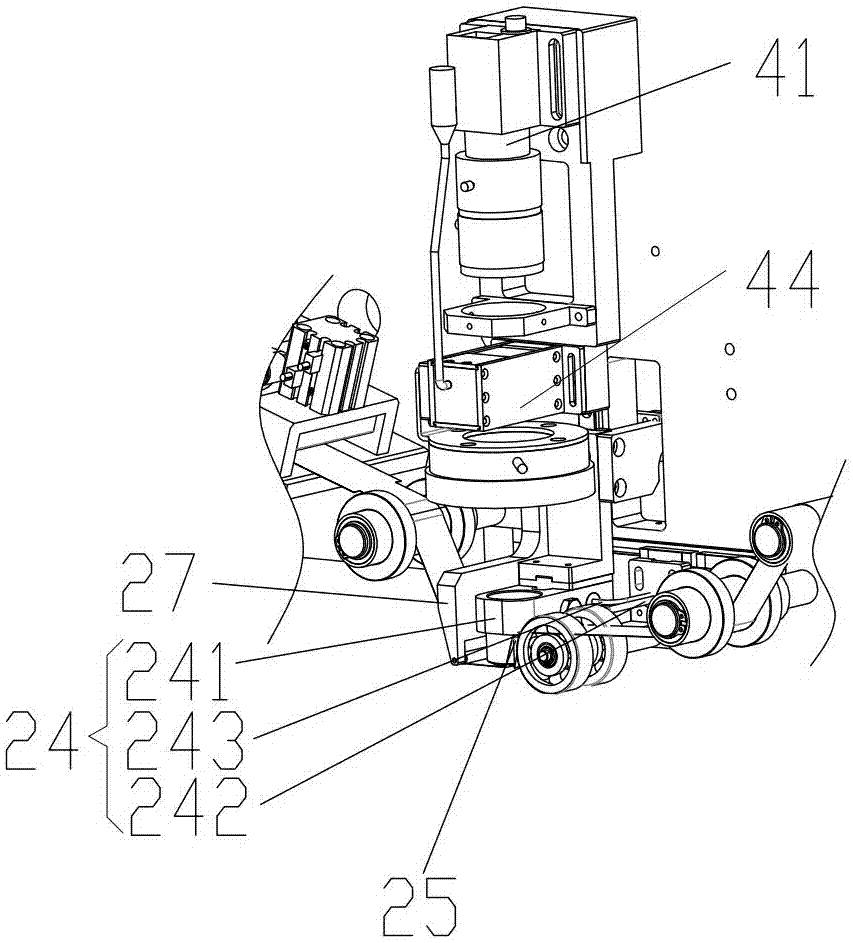

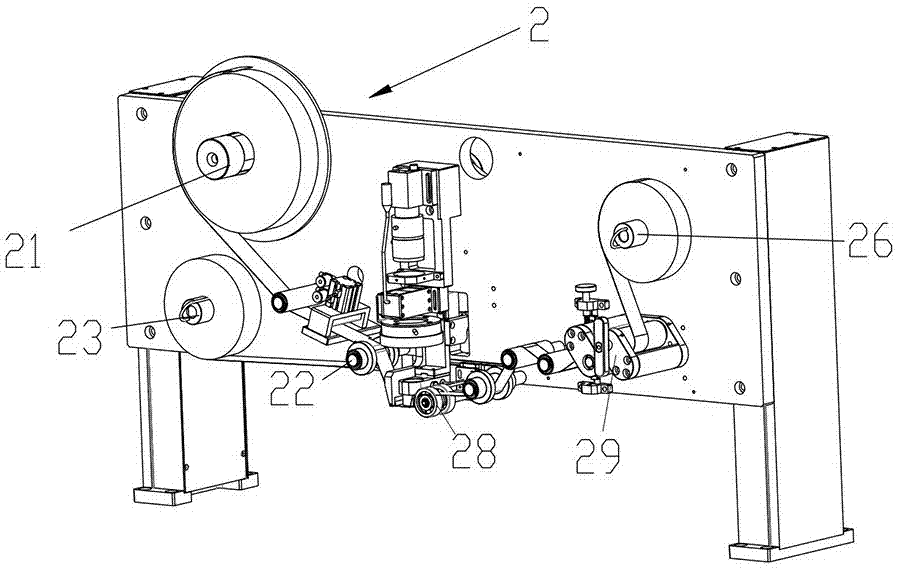

[0031] A laminating machine for semiconductor film sticking described in this embodiment, such as figure 1 As shown, it includes a retrieving device 1 for loading and unloading operations on the semiconductor carrier, a film attaching device 2 for attaching films to multiple semiconductors on the semiconductor carrier, and reciprocating between the retrieving device 1 and the film attaching device 2 for moving Material transfer device 3 for semiconductor loading. Such as figure 1 As shown, when it is necessary to carry out film-attaching operations on multiple semiconductors on the semiconductor carrier, the semiconductor carrier can be automatically moved by the pick-up device 1 to the semiconductor carrier and the material transfer device 3 to move back and forth on the semiconductor carrier. Complete the loading and unloading operation. In addition, a detection device 4 for de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com