Electric energy recycling and heat dissipation device of big-power IGBT device

A technology of electric energy recovery and heat dissipation device, which is applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of low power generation efficiency and energy waste due to temperature difference, and achieve effective energy utilization and high power generation stability Effects on Sex and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

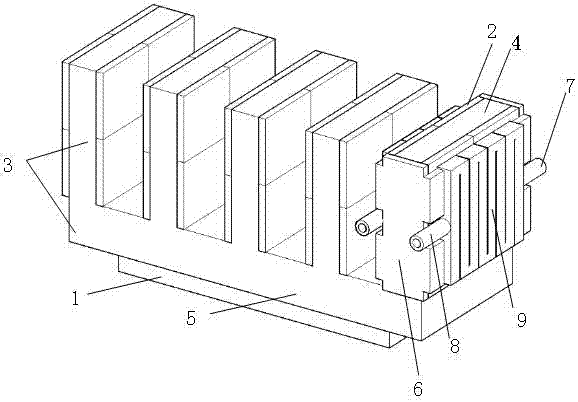

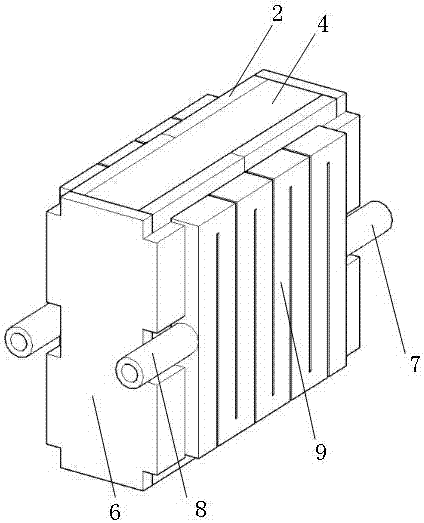

[0019] In order to make the present invention clearer, preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

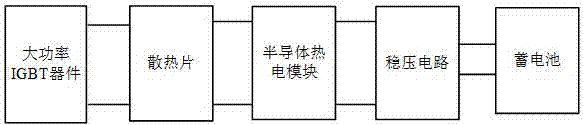

[0020] A high-power IGBT device electric energy recovery cooling device in this example includes a high-power IGBT device, a heat sink, a semiconductor thermoelectric module, a voltage stabilizing circuit, a storage battery and a water-cooling pipeline. This device connects the output ends of the voltage stabilizing circuits behind several semiconductor thermoelectric modules in series and in parallel to ensure the final output of sufficient electric power.

[0021] like figure 1 Shown is the principle block diagram of the present invention, the fin 4 is fixed together with the thermoelectric power generation sheet 2 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com