Miniature feedback cavity sensor and its manufacturing method

A sensor and miniature technology, which is applied in the direction of electrostatic transducer microphone, loudspeaker, electrical components, etc., can solve the problems of mass production that cannot be manufactured, the bulky size of miniature microphones, and not suitable for chip integration, etc., to achieve increased volume, Effects of downsizing and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

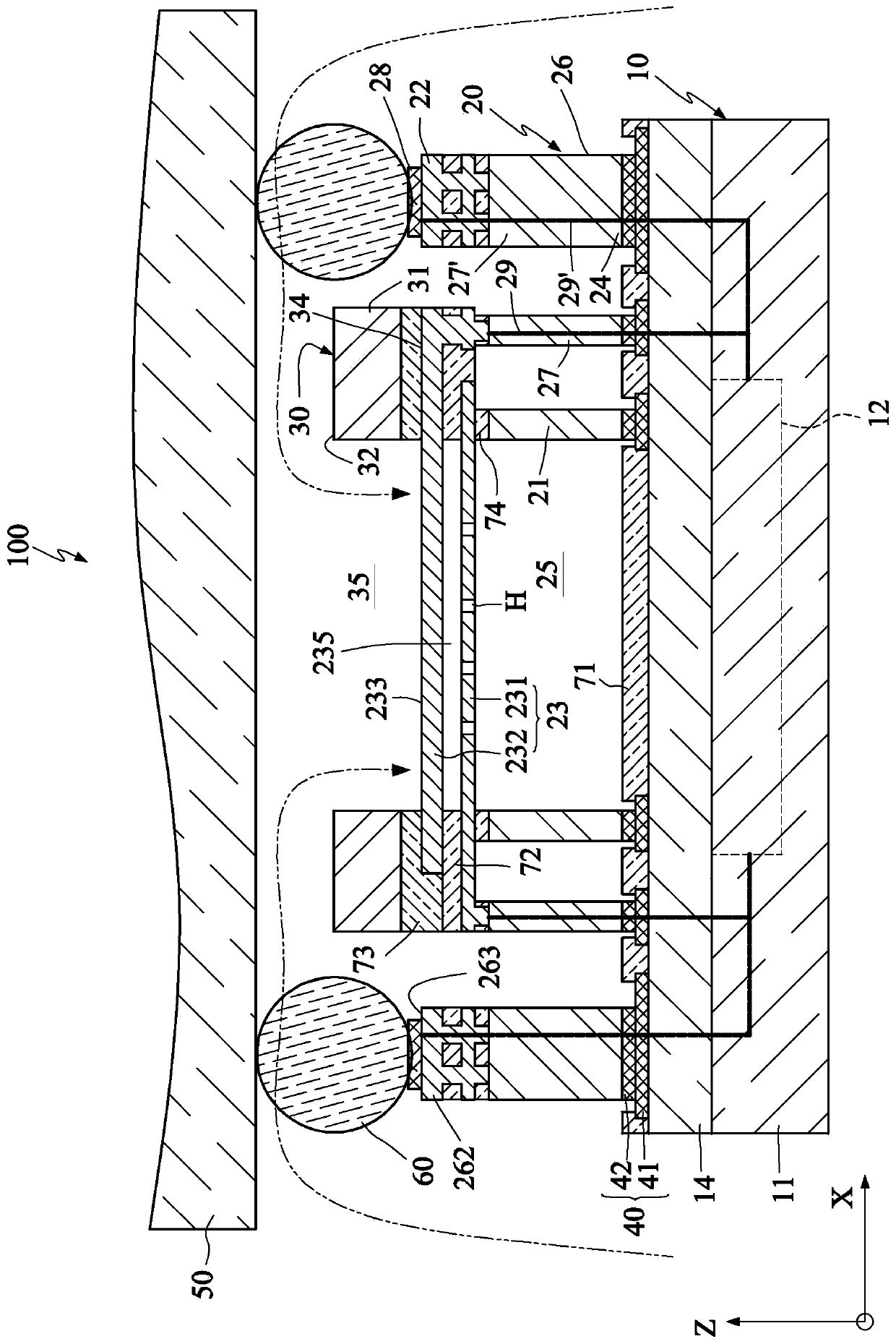

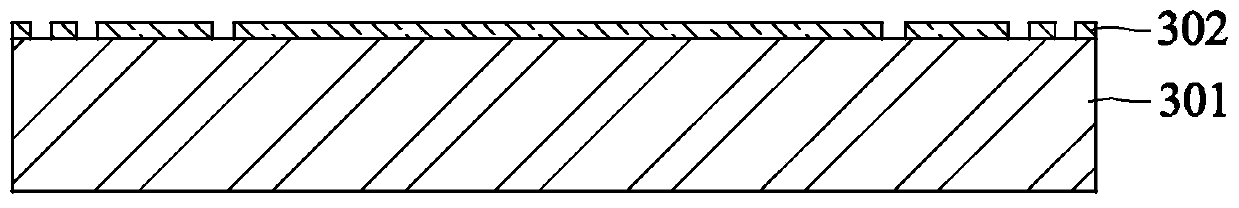

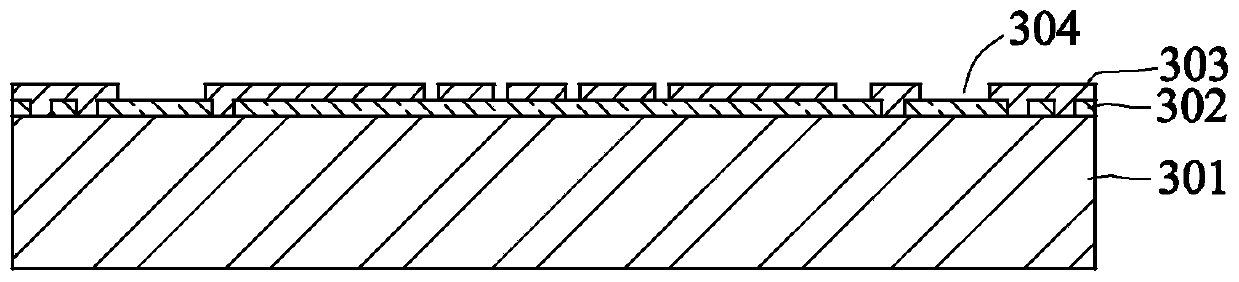

[0047] The miniature feedback cavity sensor with feedback cavity design in the embodiment of the present invention can be used as an acoustic wave sensor (such as a microphone), an ultrasonic sensor, or can be used as a pressure sensor, or can have functions such as a microphone and a pressure sensor at the same time , to achieve the effect of sensor integration. Of course, it is not limited to this, and other types of sensors that can improve the quality of the sensor through the design of the feedback cavity, such as thermal-type (thermal-type), mobile (motion-type) and other sensors can also be applied to the present invention structure and manufacturing process. In addition, the present invention utilizes wafer-level manufacturing technology, which enables mass production and reduces costs. Furthermore, the present invention completely abandons the traditional packaging method to manufacture the volume of the working cavity (back cavity), and fully utilizes the wafer-leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com