Uncovering method of soft-hard combined plate

A technology of flexible and rigid boards and hard boards, which is applied to the removal of conductive materials by chemical/electrolytic methods, multi-layer circuit manufacturing, and electrical components. Problems such as the inability to manually peel off the cover plate can achieve the effect of improving the factory's process capability and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for uncovering a rigid-flex board includes the following steps:

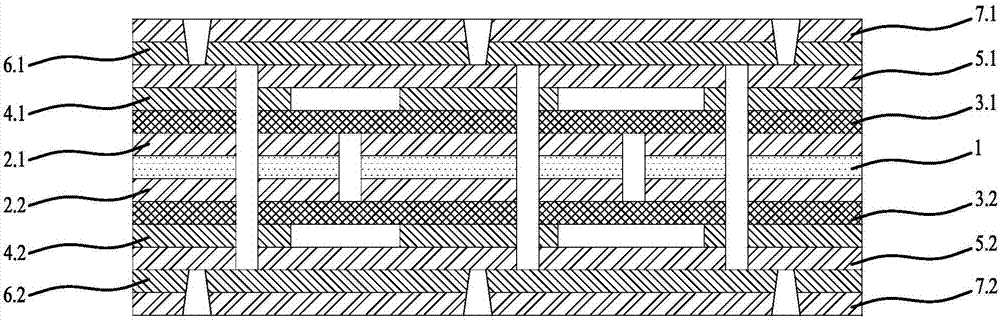

[0022] a. Take the prefabricated rigid-flex board, which includes a soft-board substrate 1, a first soft-board copper foil 2.1, a second soft-board copper foil 2.2, a first cover film 3.1, and a second cover film 3.2, the first basic prepreg 4.1, the second basic prepreg 4.2, the first basic hard board copper foil 5.1, the second basic hard board copper foil 5.2, the first additional prepreg 6.1, the second additional prepreg 6.2, the first additional hard board copper Foil 7.1 and the second additional hard board copper foil 7.2, the number of the first additional hard board copper foil 7.1 and the second additional hard board copper foil 7.2 are the same, a first window is opened on the first base prepreg 4.1, and the second base There is a second window on the prepreg 4.2, and the position of the first window corresponds to the second window; the first flexible board copper foil 2.1 is connect...

Embodiment 2

[0027] A method for uncovering a rigid-flex board includes the following steps:

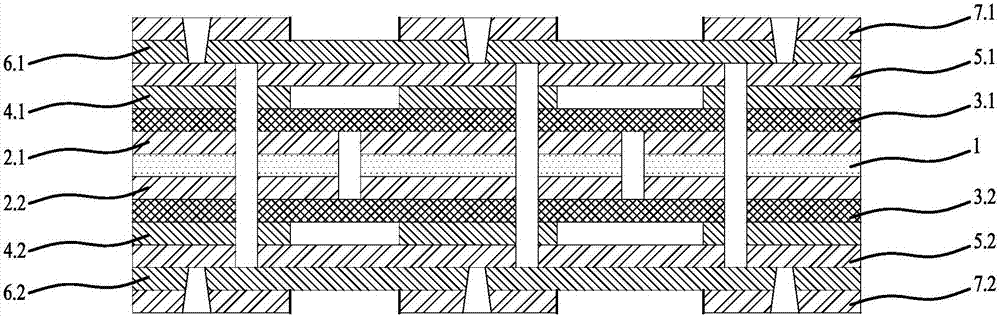

[0028] a. Take the prefabricated rigid-flex board, which includes a soft-board substrate 1, a first soft-board copper foil 2.1, a second soft-board copper foil 2.2, a first cover film 3.1, and a second cover film 3.2, the first basic prepreg 4.1, the second basic prepreg 4.2, the first basic hard board copper foil 5.1, the second basic hard board copper foil 5.2, the first additional prepreg 6.1, the second additional prepreg 6.2, the first additional hard board copper Foil 7.1 and the second additional hard board copper foil 7.2, the number of the first additional hard board copper foil 7.1 and the second additional hard board copper foil 7.2 are the same, a first window is opened on the first base prepreg 4.1, and the second base There is a second window on the prepreg 4.2, and the position of the first window corresponds to the second window; the first flexible board copper foil 2.1 is connect...

Embodiment 3

[0034] A method for uncovering a rigid-flex board includes the following steps:

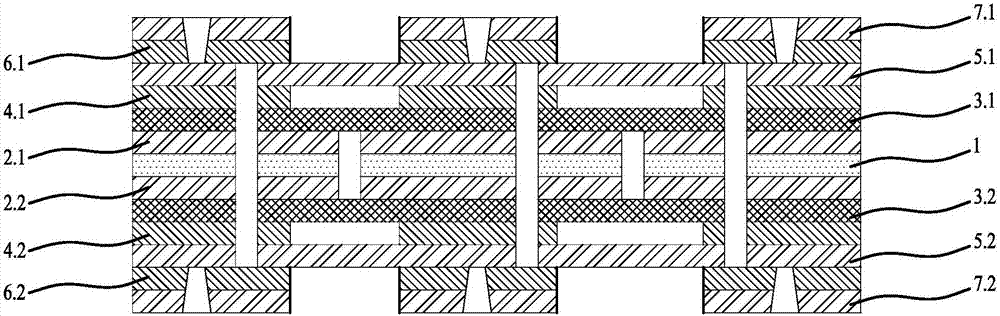

[0035]a. Take the prefabricated rigid-flex board, which includes a soft-board substrate 1, a first soft-board copper foil 2.1, a second soft-board copper foil 2.2, a first cover film 3.1, and a second cover film 3.2, the first basic prepreg 4.1, the second basic prepreg 4.2, the first basic hard board copper foil 5.1, the second basic hard board copper foil 5.2, the first additional prepreg 6.1, the second additional prepreg 6.2, the first additional hard board copper Foil 7.1 and the second additional hard board copper foil 7.2, the number of the first additional hard board copper foil 7.1 and the second additional hard board copper foil 7.2 are the same, a first window is opened on the first base prepreg 4.1, and the second base There is a second window on the prepreg 4.2, and the position of the first window corresponds to the second window; the first flexible board copper foil 2.1 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com