Deep water culture net cage

A cage and deep water technology, applied in the field of aquaculture cages, can solve the problems of insufficient mature cage lifting technology, complicated and time-consuming operation process, poor wind and wave resistance of cages, etc. The effect of improving the ability to withstand strong wind and waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

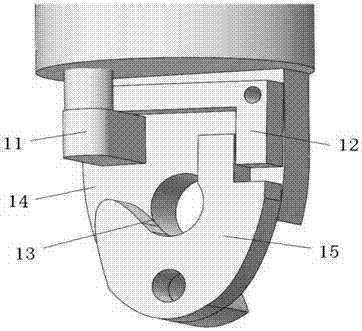

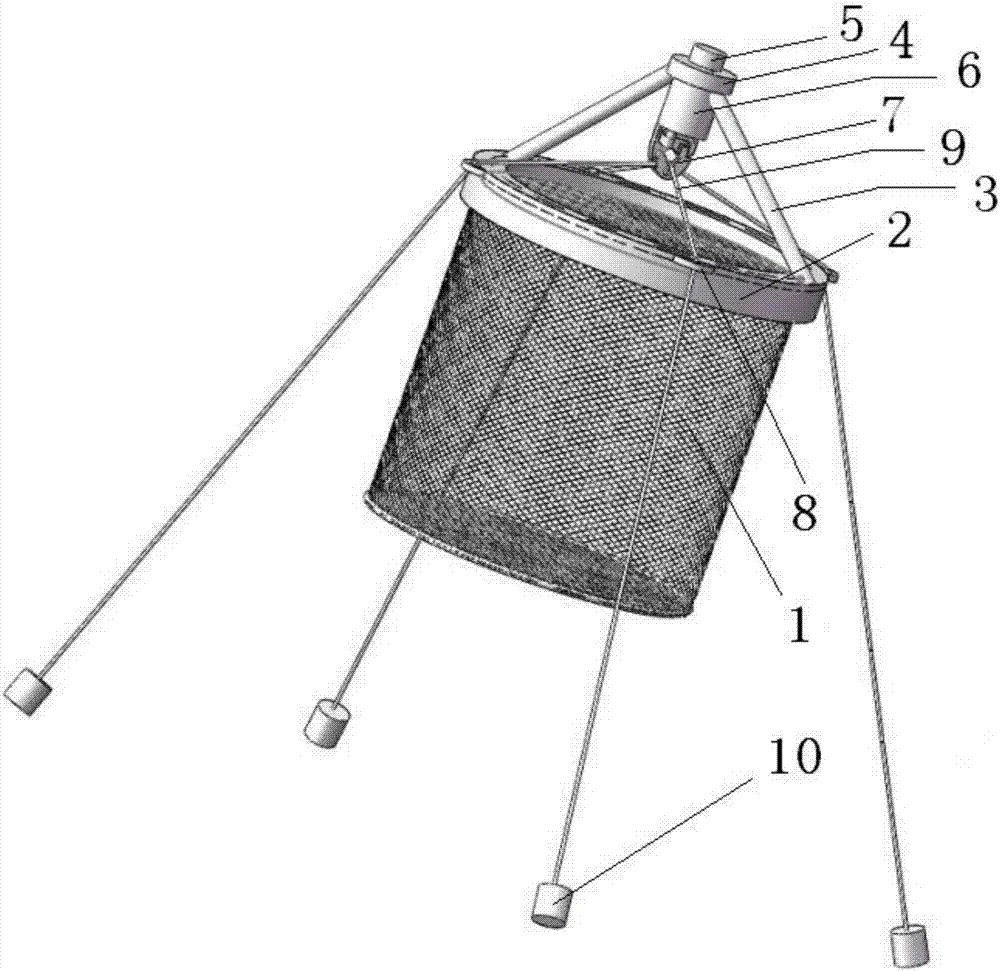

[0014] Such as figure 1 As shown, the present invention provides a deep-water culture cage, which includes a net 1, a floating body ring 2, a rigid support 3, a support plate 4, an underwater acoustic transducer 5, an electronic warehouse 6 and a release device 7.

[0015] The netting 1 adopts a cylindrical structure, and a floating body ring 2 is arranged on the top periphery of the netting 1, and the floating body ring 2 is made of a buoyant material. The periphery of the floating body ring 2 is connected with the support plate 4 through the rigid support 3 , and the support plate 4 is supported by the rigid support 3 and located in the middle above the floating body ring 2 . An underwater acoustic transducer 5 is arranged on the upper part of the support plate 4, and the release signal from the surface ship is received through the underwater acous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com