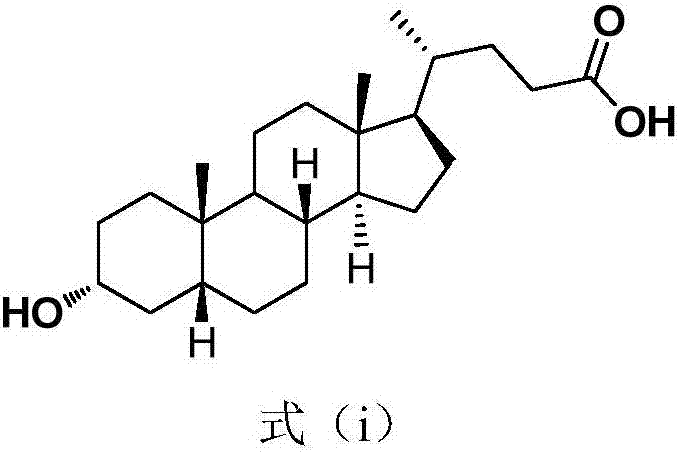

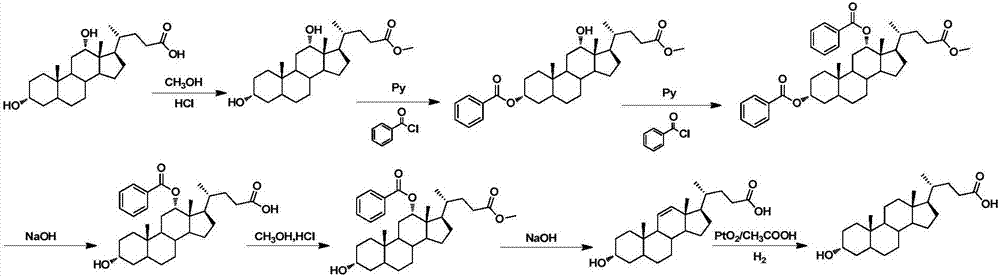

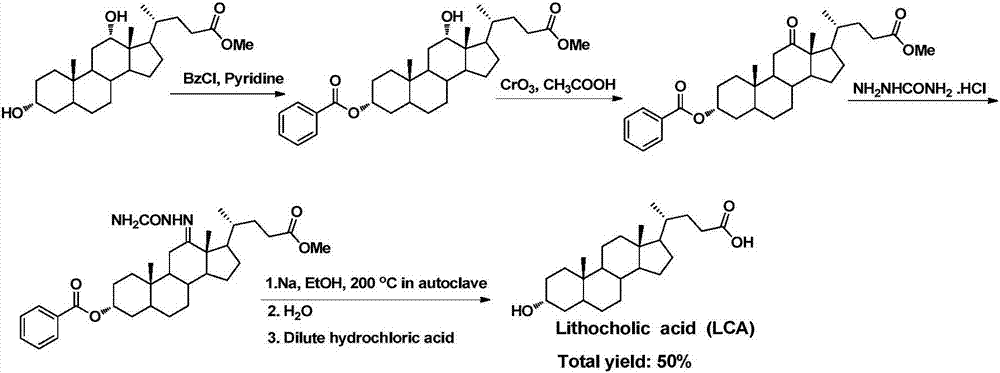

Method for synthesizing lithocholic acid from hyodesoxycholic acid

A technique for synthesizing hyodeoxycholic acid and its synthesis method, which is applied in the field of synthesizing lithocholic acid, can solve the problems of high reaction risk factor, unfavorable industrialization, long synthesis route, etc., and achieve less side reactions, high total yield, and simple post-treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1, the synthesis of formula (2) compound

[0038]

[0039] Hyodeoxycholic acid (5 g, 12.7 mol) was dissolved in a mixed solvent of acetone (50 mL) and water (25 mL), NBS (3.95 g, 22.2 mmol) was added, and reacted at room temperature for 2 hours in the dark. After TLC detects that the reaction of raw materials is complete, add 30 mL of saturated NaHSO 3 The solution quenched the reaction. Add 200 mL of water and 30 mL of dichloromethane, and stir at room temperature for 10 minutes. The layers were separated, and the aqueous phase was extracted with dichloromethane (40 mL×4). The organic phases were combined, washed successively with saturated brine (30mL×1), anhydrous Na 2 SO 4 dry. Concentrate under reduced pressure and purify by silica gel column chromatography (DCM:MeOH=40:1) to obtain the compound of formula (2) (white solid, 4.5 g), with a mass yield of 90%. 1 H NMR (400MHz, DMSO-d 6 )δ 3.42–3.33 (m, 1H), 0.89 (d, J=6.4Hz, 3H), 0.74 (s, 3H), 0.61 (s, 3H). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com