Truss-type composite steel plate wall

A combined steel plate wall and truss technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of increased construction cost, danger of high-altitude work, long construction period, etc. The effect of stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

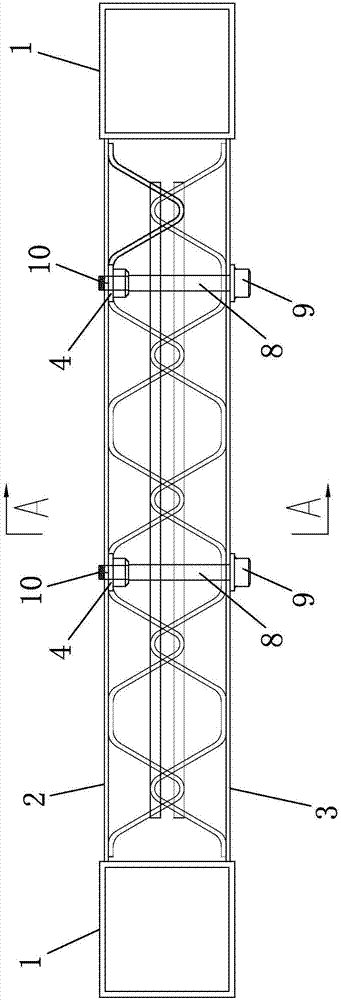

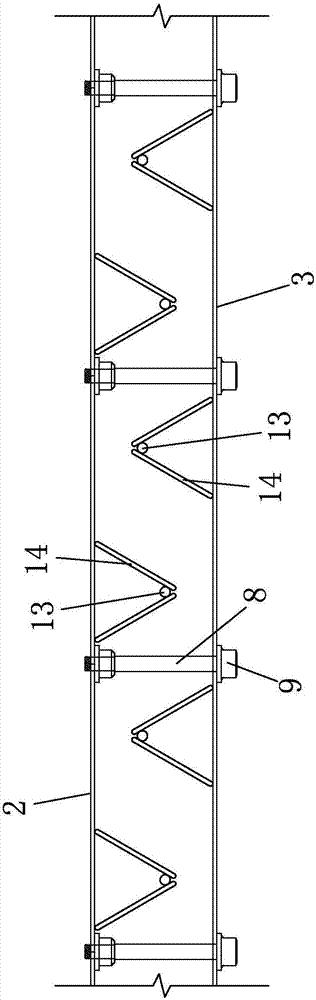

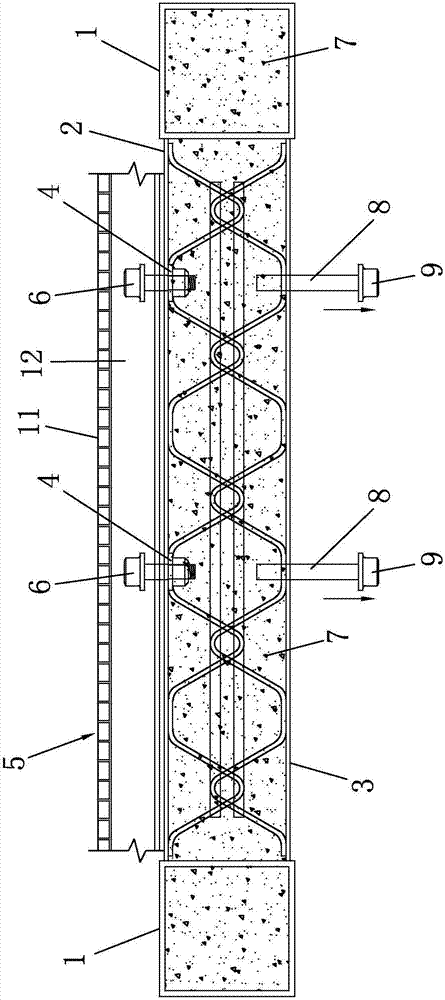

[0027] Such as Figure 1 to Figure 4 As shown, it is a truss-type combined steel plate wall of the present invention, including end columns 1, first steel plates 2, second steel plates 3 and concrete 7, the first steel plates 2 and the second steel plates 3 are arranged between the end columns 1, and the second The first steel plate 2 and the second steel plate 3 are used as templates in the process of pouring concrete 7, which is convenient for pouring and does not require formwork, and the construction is fast. The end column 1 is one of cold-formed square tubes, cold-formed rectangular flat columns, welded square columns, welded rectangular flat columns, hot-rolled H-shaped steel, and welded H-shaped steel. It has a wide range of applications. The first steel plate 2 and the second steel plate 3 is automatically welded with terminal post 1. Concrete 7 is one of ordinary concrete, high-strength concrete, and lightweight aggregate concrete, and has a wide range of applicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com