Tunnel secondary lining width adjustable concrete end mold and adjusting method thereof

A secondary lining and adjustable technology, used in tunnel lining, tunnel, wellbore lining and other directions, can solve the problem that the back-mounted water stop can not play the role of water stop, and achieve strong promotion significance, save construction costs, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

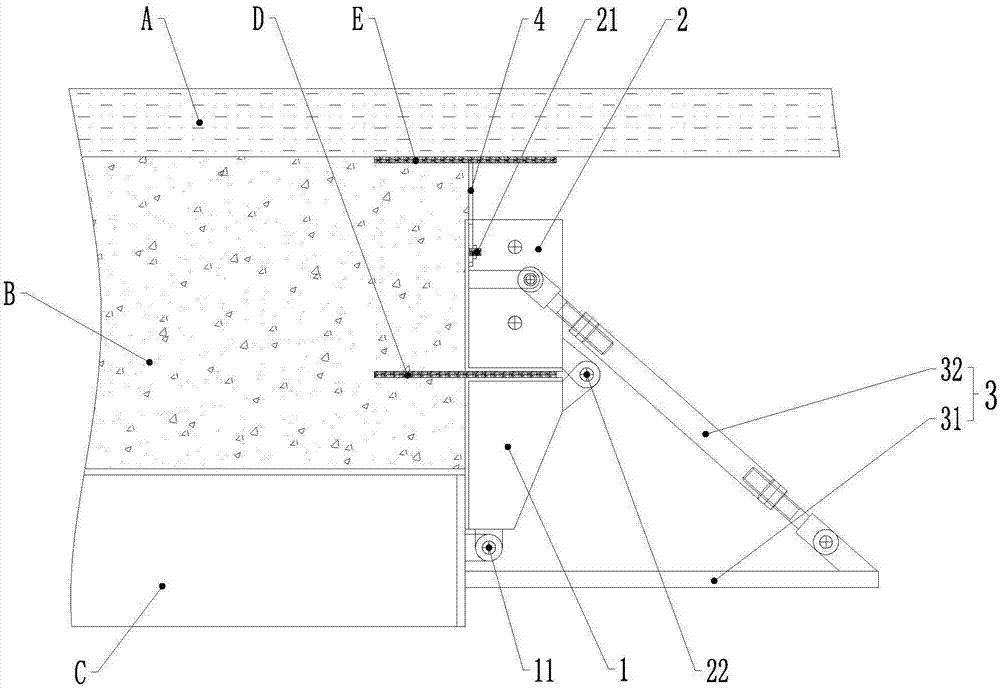

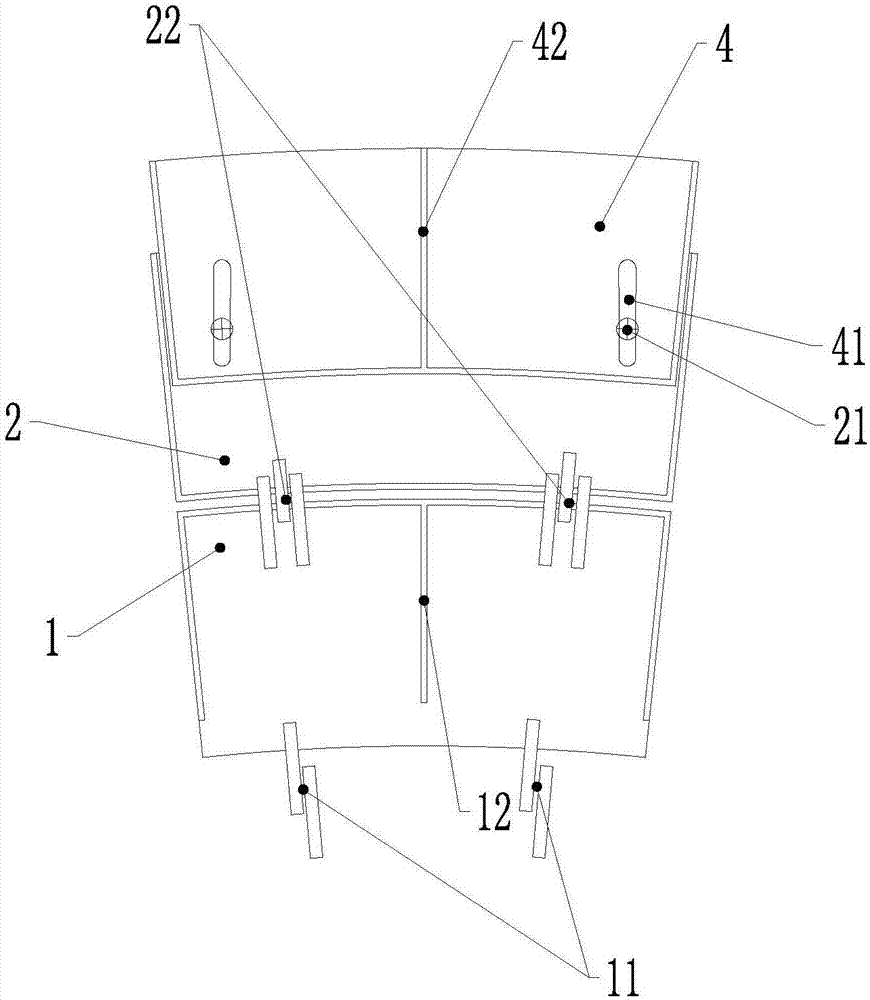

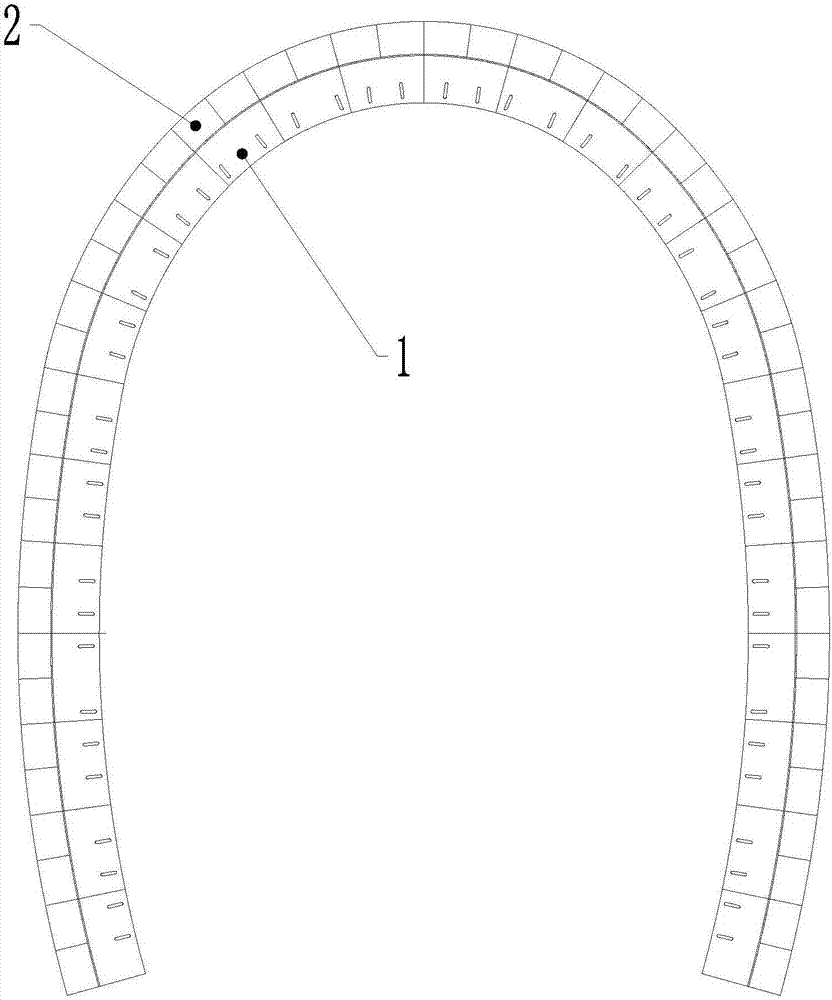

[0033] Concrete end formwork with adjustable width for the secondary lining of the tunnel, specifically, such as figure 1 , 2 As shown, it includes an inner side mold 1 and an outer side mold 2 hinged to each other, the inner side mold 1 is connected to the trolley body C, and it is characterized in that: the outer side mold 2 is slidably connected with an extension plate 4, and The direction of relative sliding is along the radial direction of the sector of the outer end mold 2.

[0034] The specific structure of the sliding connection includes: an elongated hole 41 arranged on the extension plate 4, a fixed shaft 21 matching the elongated hole 41 is arranged on the outer end mold 2, and the fixed shaft 21 passes through the The elongated hole 11 and the nut are sleeved to fix the extension plate 4 on the outer end mold 2 .

[0035] Also comprise telescopic support 3, described telescopic support 3 comprises pole 31 and telescoping rod 32; One end of described pole 31 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com