A modification method of thermoelectric decoupling system for steam turbine low-pressure cylinder high-vacuum de-cylinder operation

A low-pressure cylinder and steam turbine technology, applied in the application field of thermal power generation units, can solve the problems of poor operating economy of the reformed unit, changes in the thrust of the steam turbine, and affecting the safety of the unit, so as to achieve low-grade heat source, low heating cost, and low heat supply. Good economical effect of thermal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

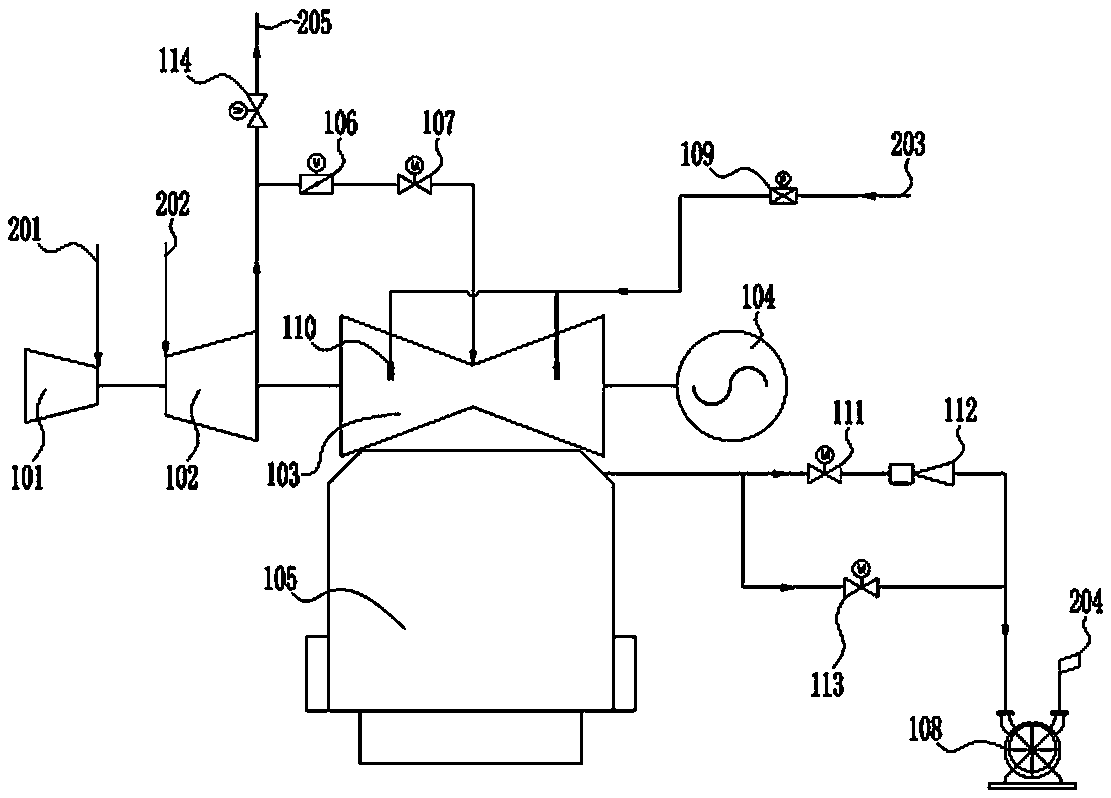

[0035] Refer to the attached figure 1 , in order to solve the above-mentioned problems in the prior art, the present invention provides a kind of transformation method of thermoelectric decoupling system of steam turbine low-pressure cylinder high-vacuum de-cylinder operation, said system mainly includes steam turbine high-pressure cylinder 101, steam turbine medium-pressure cylinder 102, steam turbine Low-pressure cylinder 103, generator 104, condenser 105, medium-low pressure cylinder connecting and regulating butterfly valve 106, low-pressure cylinder inlet steam isolation valve 107, water ring vacuum pump 108, low-pressure cylinder desuperheating water regulating valve 109, low-pressure cylinder spraying water to reduce temperature device 110, pre-vacuum device stop valve 111, pre-vacuum device 112, pre-vacuum device bypass stop valve 113, heating and extraction stop valve 114, main steam 201, reheat steam 202, low-pressure cylinder injection Water desuperheating water 203...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com