A non-contact glass brick refraction index measuring instrument

A non-contact, glass brick technology, applied in the measurement of phase influence characteristics, etc., can solve the problems of affecting the physical properties of glass bricks, immovable glass, glass surface wear, etc., to achieve automatic device adjustment and measurement, and good parallelism. , the effect of high brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] specific implementation plan

[0027] The present invention will be further described below in conjunction with the accompanying drawings of the description.

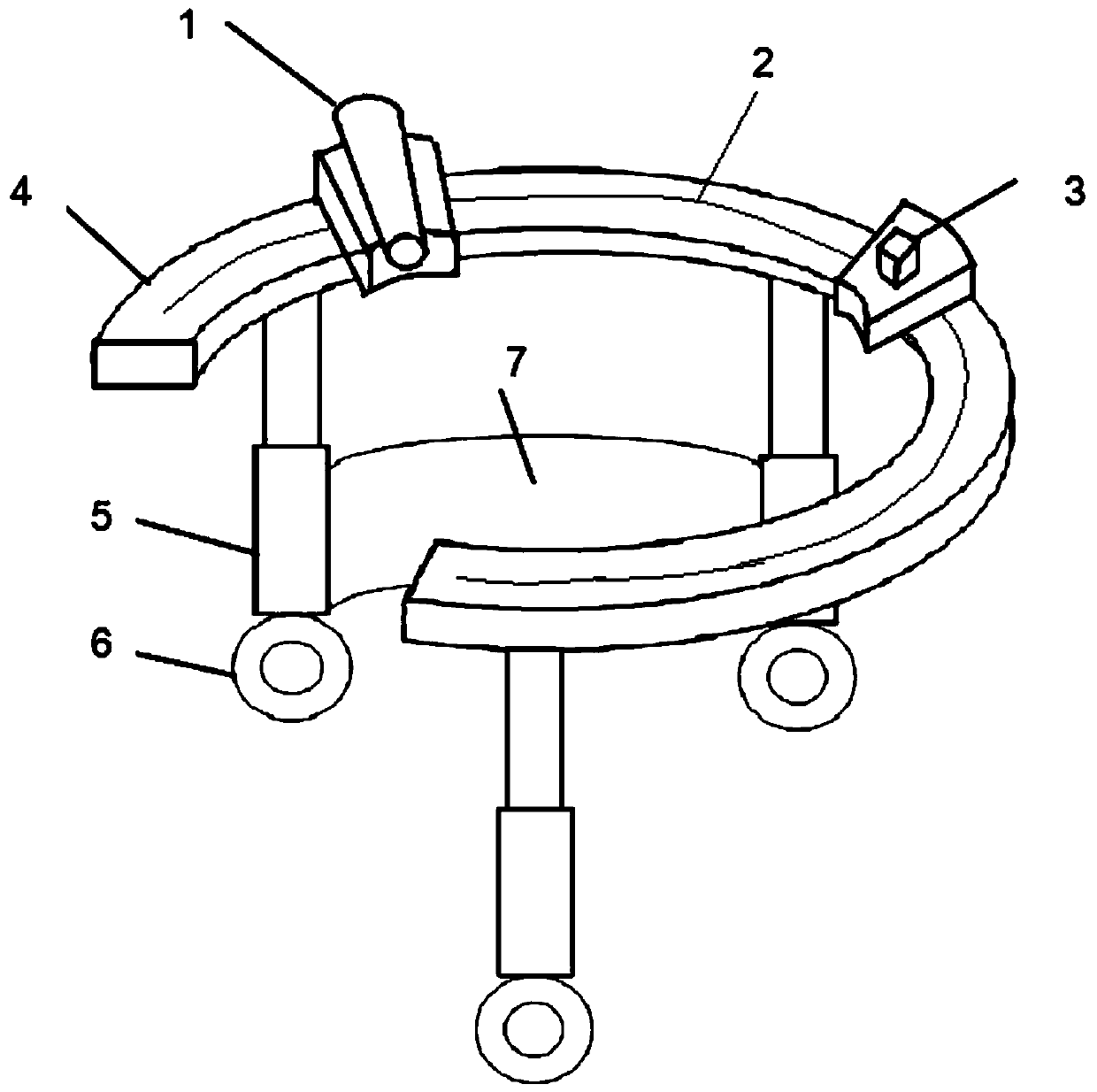

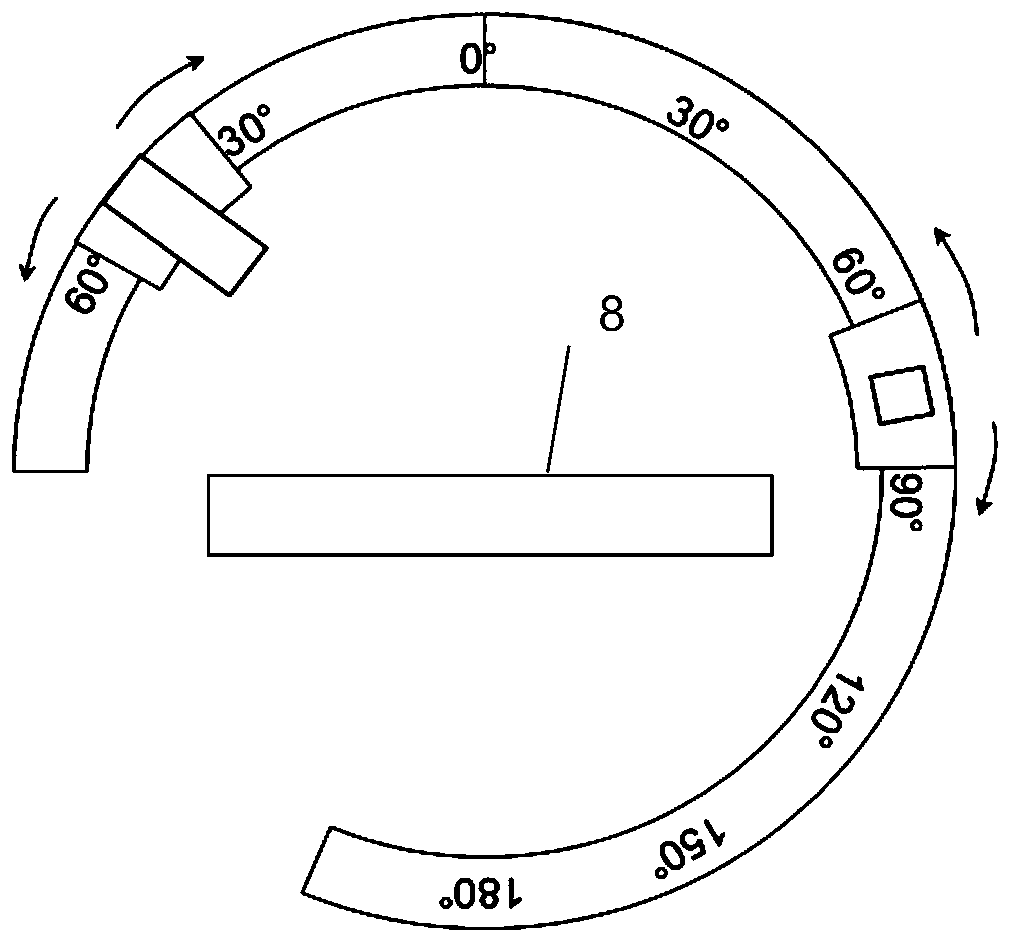

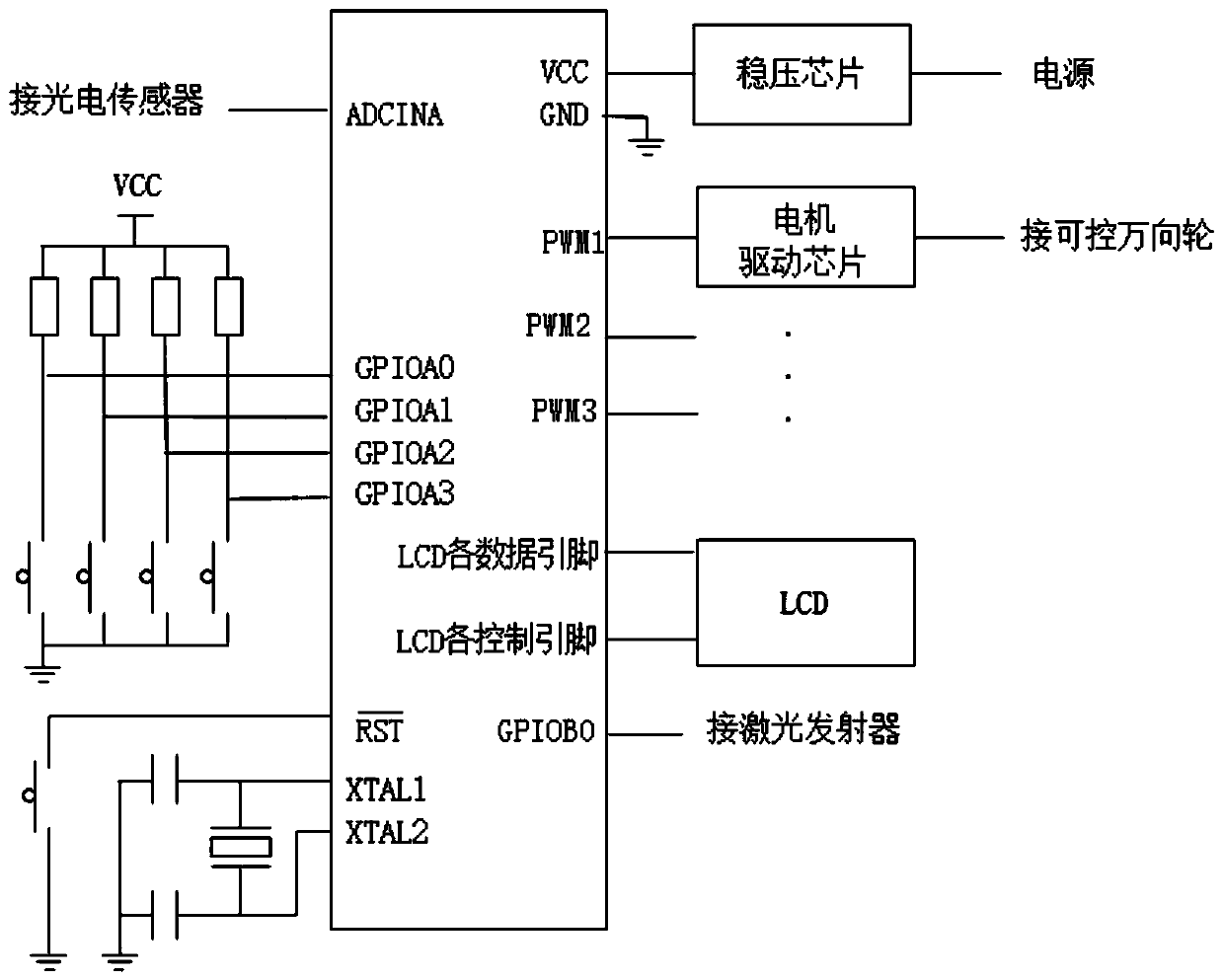

[0028] Such as Figure 1-3 As shown, it includes a laser emitting device, a light intensity detection device, a fixed ring 4, a telescopic support frame 5, a controllable universal wheel 6, and a circuit board control module 7.

[0029] The laser emitting device is composed of a laser emitter 1 and a polarizer. The polarizer is installed at the emission exit of the laser emitter 1, and the direction of vibration transmission allowed by the polarizer in the polarizer is horizontal. Since only light waves whose vibration direction is parallel to the vibration transmission direction can pass through the polarizer, the finally emitted laser light is polarized light with a horizontal polarization direction. Then when the incident angle is Brewster's angle, there will be no reflected light.

[0030] The light inten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com