Film thickness and refractive index simultaneous measurement device and measurement method

A technology of film thickness and measurement method, which is applied in the field of optical measurement, can solve problems such as the inability to eliminate laser transmitted light, the destruction of film surface morphology, and the difficulty of demodulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

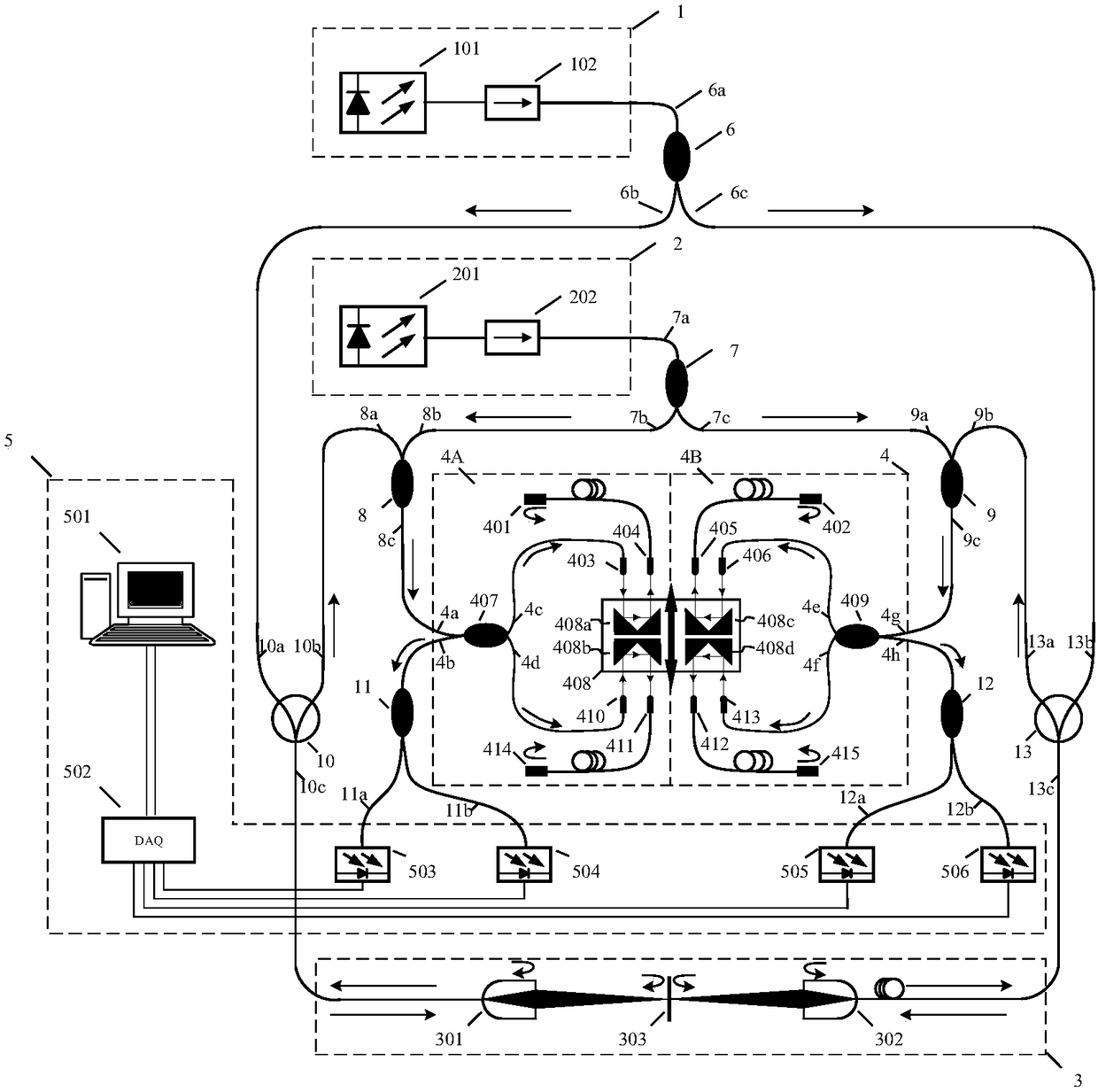

[0054] The overall technical scheme of the present invention is as figure 1 shown. The wide-spectrum light output module 1 is composed of a wide-spectrum light source 101 with a center wavelength of 1310nm and a first isolator 102 with an operating wavelength of 1310nm. The wide-spectrum light source 101 is used as a measurement light source and is mainly used to achieve absolute measurement of film thickness; The wide laser output module is composed of a narrow linewidth laser light source 201 with a wavelength of 1550nm and a second isolator 202 with an operating wavelength of 1550nm. The narrow linewidth frequency-stabilized laser light source 103 is used as the optical path correction light source, mainly used to realize the traceability of film thickness measurement . The light emitted by the wide-spectrum light source 101 enters the beam-splitting coupler 2 with a splitting ratio of 3dB through the first isolator 102, and is divided into two paths, passing through the ...

Embodiment 2

[0060] A device for simultaneous measurement of film thickness and refractive index consists of five parts: a wide-spectrum light output module 1, a narrow linewidth laser output module 2, a film thickness measurement probe module 3, a demodulation interferometer module 4, and an acquisition and control module 5. ;

[0061]The output light of the wide-spectrum light output module 1 is divided into two paths through the first beam splitter coupler 6 and enters the first measuring probe 301 and the second measuring probe 301 of the film thickness measuring probe module 3 through the first circulator 10 and the second circulator 13 respectively. In the measuring probe 302; the return light via the first measuring probe 301 and the second measuring probe 302 enters the first wavelength division multiplexer 8 and the second wavelength division multiplexer respectively through the first circulator 10 and the second circulator 11 9 relevant wavelength input terminals;

[0062] The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com