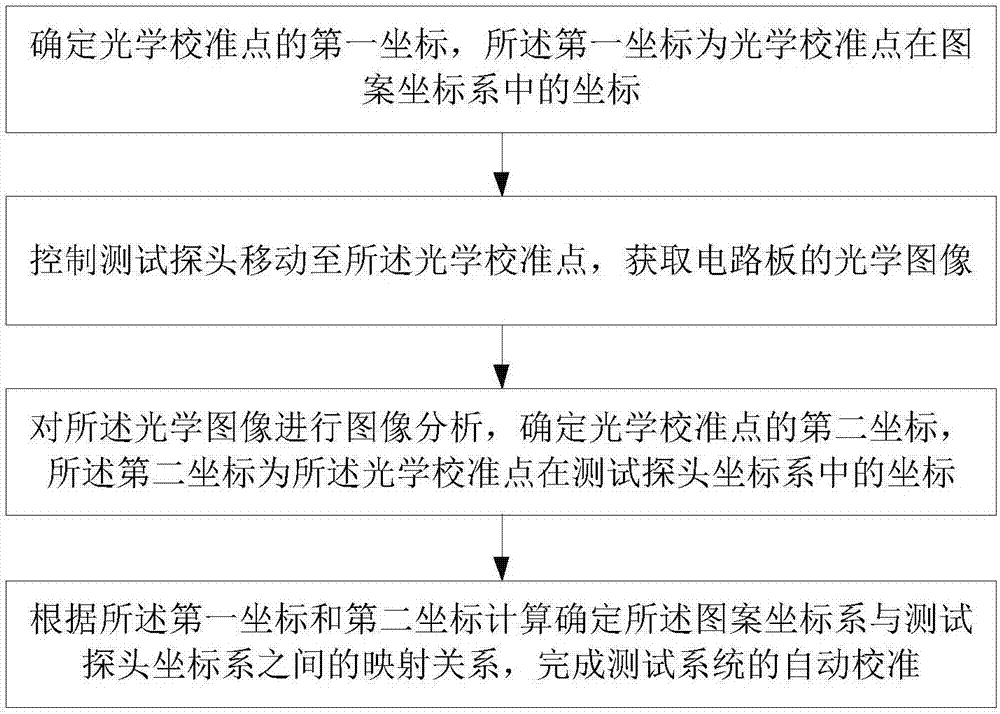

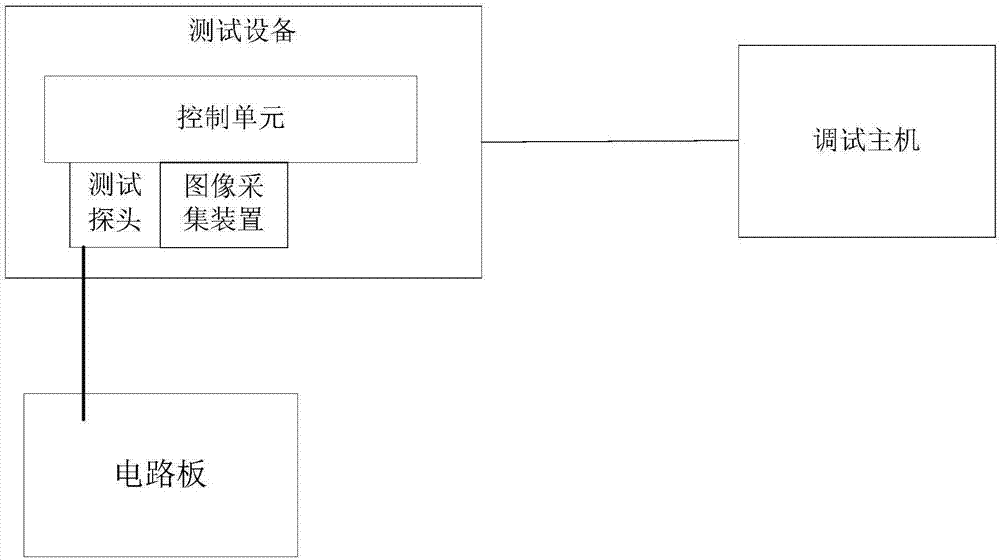

Calibration method and system for circuit board automatic test system

A technology of automatic test system and calibration method, which is applied to measuring devices, measuring electrical variables, instruments, etc., can solve problems such as time-consuming and labor-intensive, and achieve the effects of reducing manual operations, high positioning accuracy, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

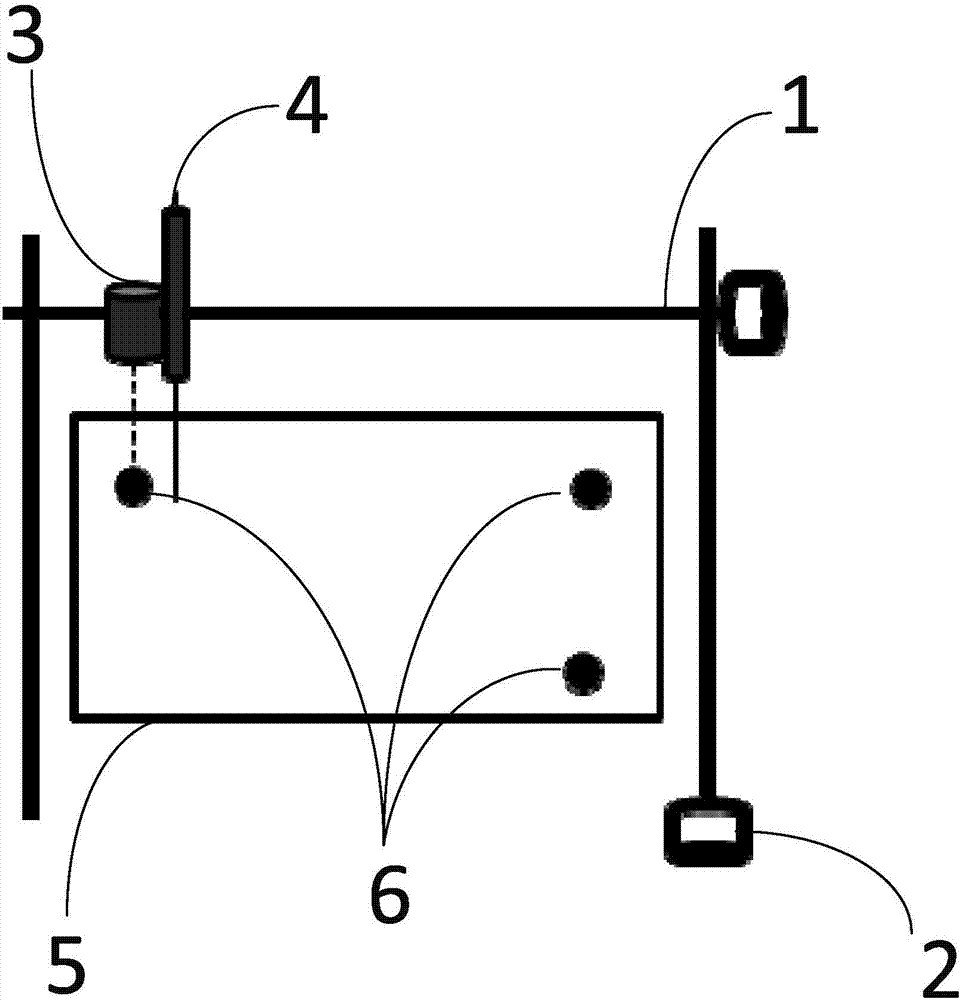

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

[0043] Such as image 3As shown, in the automatic test system of the circuit board, the schematic diagram of the PCB circuit board is stored in the host computer, and the pattern coordinate system (PQ coordinate system) of the schematic diagram of the PCB circuit board is determined in the host computer. In this embodiment, the pattern coordinate system is a plane Cartesian coordinate system, including a P axis and a Q axis, wherein the P axis is parallel to the horizontal direction of the PCB circuit board schematic diagram, and the Q axis is parallel to the vertical direction of the PCB circuit board schematic diagram , the origin of the pattern coordinate system is specified by the user in the host computer, generally the lower left corner of the schematic di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com