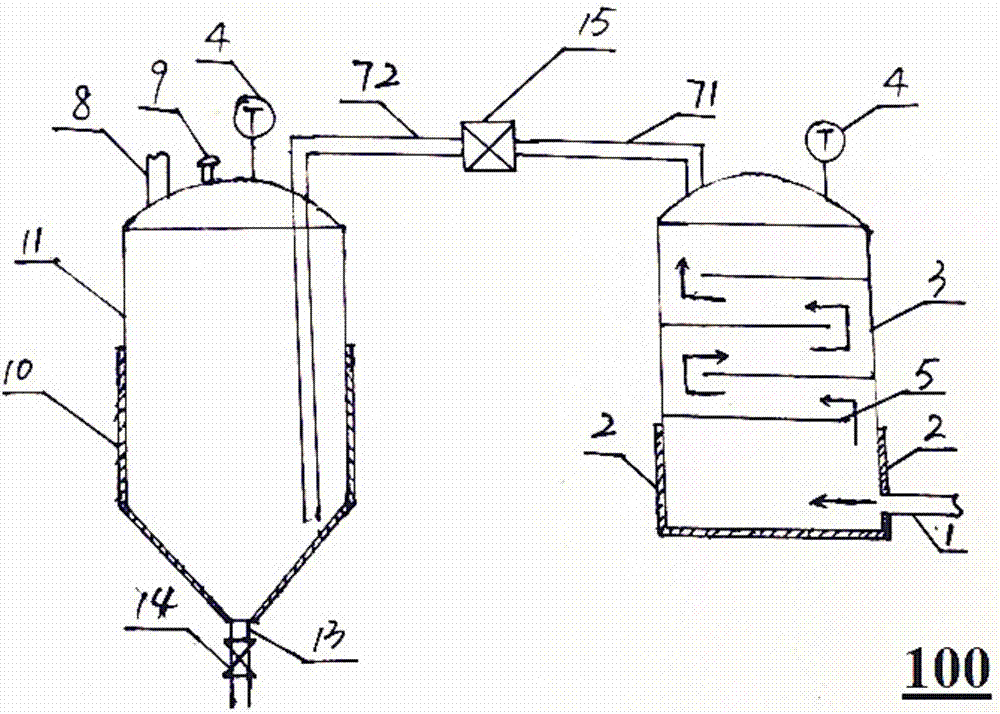

Grease aroma enhancement device and method

A grease and oil storage technology, applied in the fields of edible oil/fat, food science, application, etc., can solve the problem of easy introduction of impurities, and achieve the effect of increasing nitrogen solubility, which is beneficial to storage and food safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

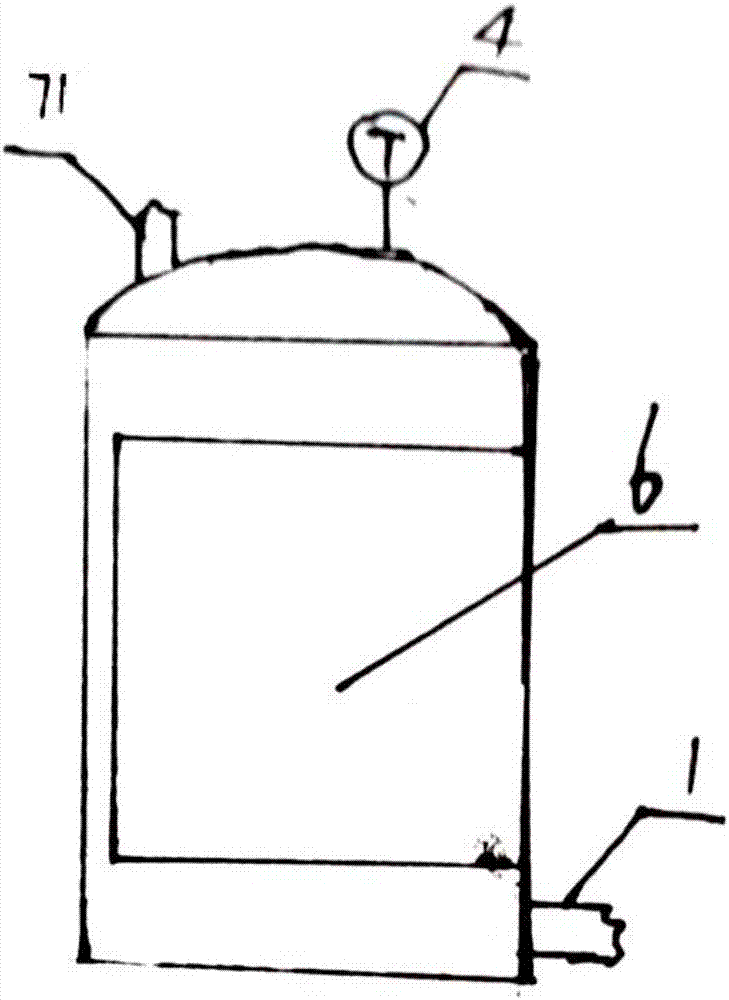

Image

Examples

Embodiment 1

[0027] Take 0.1 ton of pressed camellia seed cake and put it on the separator in the heater. After nitrogen filling and emptying, pump 5 tons of refined camellia oil into the oil storage tank and stir it. Turn on the nitrogen gas with a flow rate of 5L / min. , the heater was heated up to 140° C., and after heating for 2 hours, strong-flavored tea oil was obtained.

Embodiment 2

[0029] Take 50 kg of fresh sweet-scented osmanthus and put it on the separator in the heater. After nitrogen filling and emptying, pump 8 tons of refined rapeseed oil into the oil storage tank and stir. Turn on the nitrogen gas with a flow rate of 8L / min to raise the temperature of the heater. After heating to 100°C for 5 hours, rapeseed oil with a strong osmanthus fragrance was obtained.

Embodiment 3

[0031] Take 50 kg of cassia bark and put it on the separator in the heater. After nitrogen filling and emptying, use a pump to pump 10 tons of refined peanut oil into the oil storage tank and stir it. Turn on the nitrogen gas with a flow rate of 10 L / min, and heat the heater to After heating at 120°C for 5 hours, peanut oil with strong cinnamon aroma was obtained.

[0032] Compared with the prior art, the technical solution of the present invention has the beneficial effects of: avoiding the contact of natural spices or oil cakes with oil, and avoiding the mixing of harmful substances produced by high temperature into the oil; the inert gas promotes the dissolution of more flavor substances in the edible oil Medium, and increase the nitrogen solubility in oil, protect oil from oxidation. By using the oil flavoring device or the flavoring method provided by the invention, a fat and oil preparation method with rich natural flavor, safe food and convenient storage is provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com