Novel corrosion resisting technological method and device for separating device of gas gathering station

A separation equipment, anti-corrosion technology, applied in the direction of spraying device, device for coating liquid on the surface, special surface, etc., can solve the problems that can not achieve good results, reduce the intensity of manual work, improve continuity, advanced The effect of anti-corrosion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

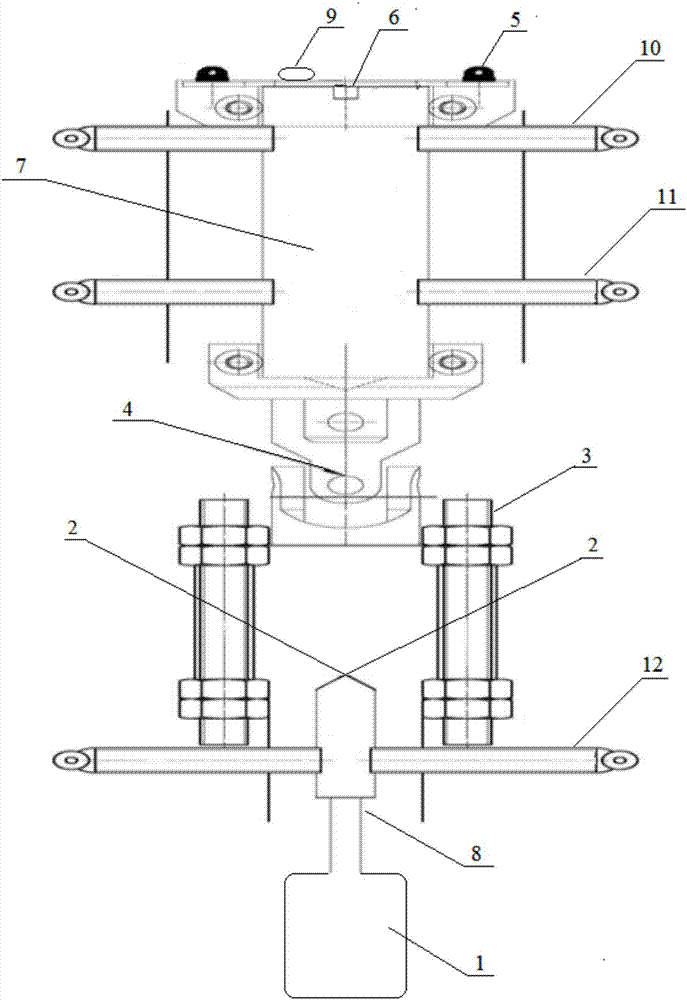

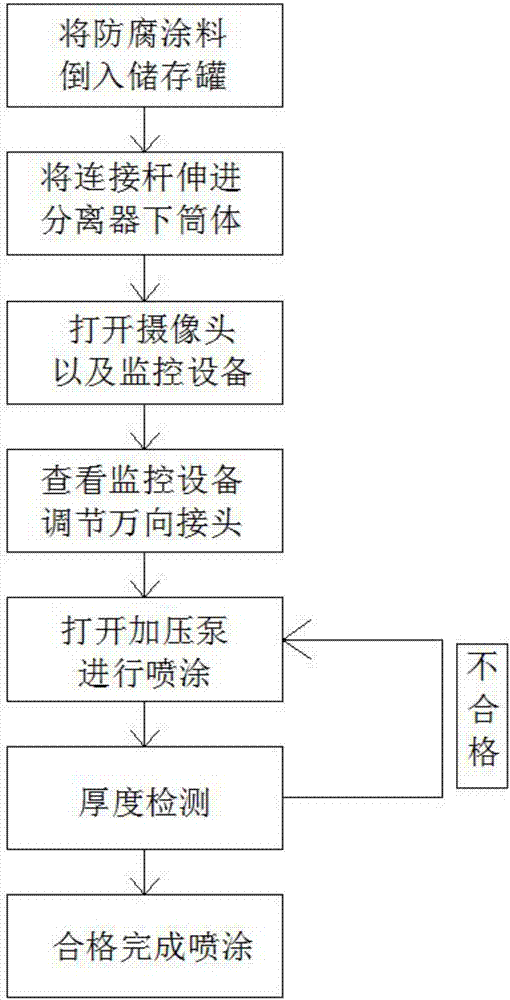

[0025] Such as figure 1 As shown, a new process method for anti-corrosion of separation equipment in a gas gathering station includes the following steps:

[0026] 1), pour the anticorrosion paint into the storage tank 1;

[0027] 2) Extend the telescopic connecting rod 3 into the coating part of the lower cylinder of the separator;

[0028] 3), turn on the camera 6 and the camera 7, and transmit the internal scene of the lower cylinder of the separator to the camera 7 in real time through the camera 6;

[0029] 4), and then adjust the universal joint 4 by checking the camera 7, so that the spray gun 2 reaches the required spraying position;

[0030] 5), turn on the pressurizing pump 13, so that the anticorrosion paint inside the storage tank 1 reaches the nozzle position of the spray gun 2 through the connecting pipe 8, and the anticorrosion paint is evenly coated on the inner wall of the lower cylinder of the separator through the spray gun 2;

[0031] 6) Anti-corrosion l...

Embodiment 2

[0034] On the basis of embodiment 1, after the step 5, connect the film thickness measuring instrument 9, open the monitor, and carry out anti-corrosion layer thickness detection and leak point inspection. If the detection thickness is unqualified or there is a missing coating part, re-spray the unqualified part until it is qualified. The film thickness measuring instrument is an ultrasonic thickness measuring instrument, and its working principle is to measure the thickness according to the principle of ultrasonic pulse reflection. When the ultrasonic pulse emitted by the probe passes through the object to be measured and reaches the interface of the material, the pulse is reflected back to the probe. Accurately measure the time that ultrasonic waves travel through the material to determine the thickness of the material being tested. All kinds of materials that can make ultrasonic waves propagate inside them at a constant speed can be measured by this principle.

Embodiment 3

[0036] Such as figure 2 As shown, a new anti-corrosion process device for the separation equipment of a gas gathering station, at least including a storage tank 1, the storage tank 1 is connected to the lower cylinder of the separator through a connecting pipe 8, and the feature is that the connecting pipe 8 extends to the separator In the lower cylinder body of the device, and the end of the extension end of the connecting pipe 8 is equipped with a spray gun 2, and in the lower cylinder body of the separator, there are supporting rotary rod one 10, supporting rotary rod two 11 and supporting rotary rod slidingly connected in sequence from top to bottom along the cylinder wall radial direction. Rod three 12, two telescopic connecting rods 3 perpendicular to it are installed on the supporting rotating rod three 12, universal joint 4 is fixed between the two telescopic connecting rods 3, universal joint 4 is fixed on the supporting rotating rod Rod one 10 links to each other wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com