Assembly line used for prearranged soup spoons in double-layer sealed packaging cup

An assembly line, packaging cup technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of small spoon pollution, difficulty in ensuring food hygiene, and inability to achieve independent packaging of small spoons in packaging cups, etc., to ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

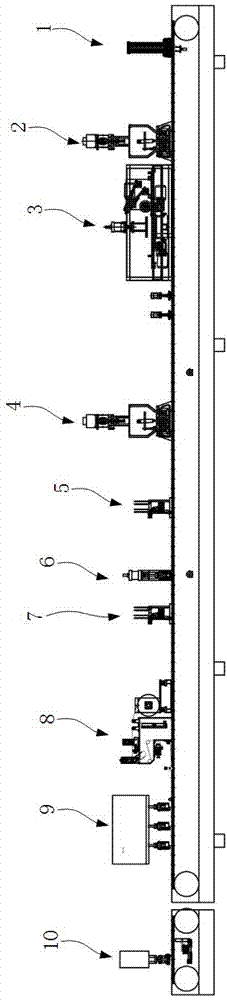

[0023] refer to figure 1 The overall structure schematic diagram of the embodiment of the present invention shown.

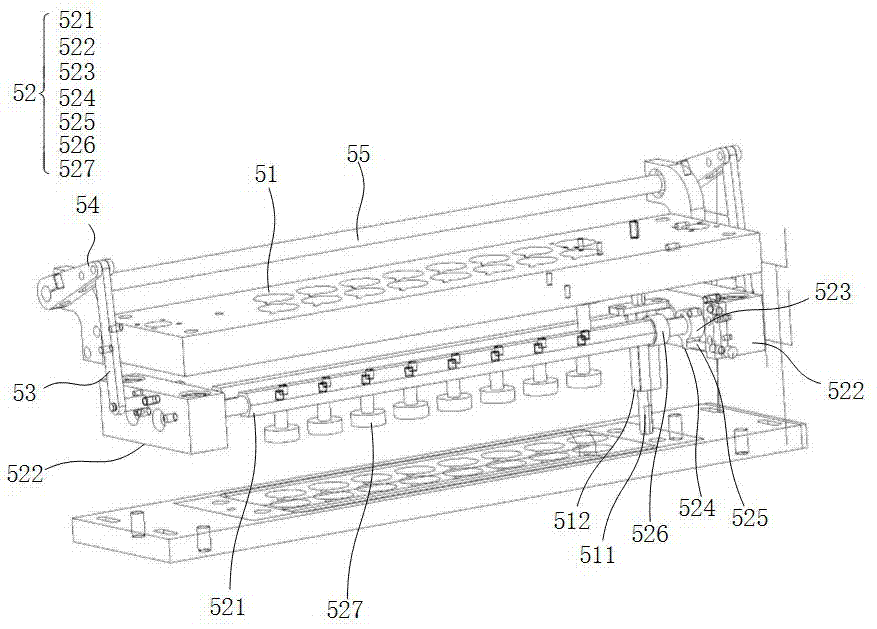

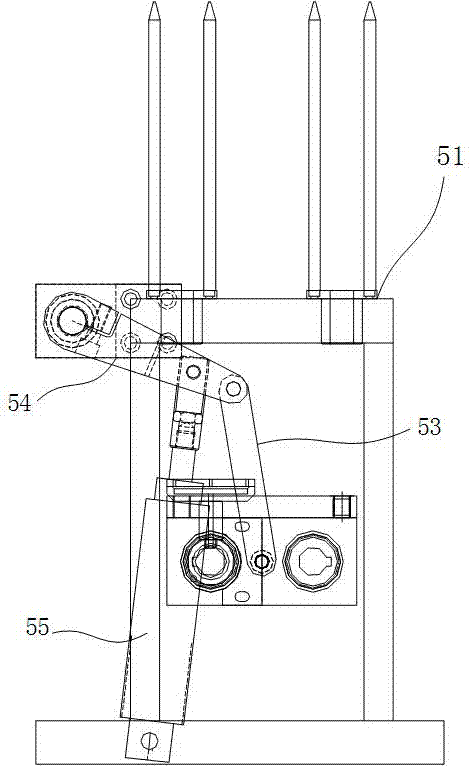

[0024] An assembly line for presetting spoons in double-layer sealed packaging cups according to an embodiment of the present invention includes a cup feeding device 1, a filling device 2, a biscuit placing device 3, a filling device 4, an inner film placing device 5, a sealing device Inner sheet device 6 , spoon putting device 7 , film putting device 8 , heat sealing device 9 and shearing device 10 .

[0025] A conveyor belt is arranged below the above-mentioned mechanism, and a concave mold for placing packaging cups is arranged on the conveyor belt. In this embodiment, the concave molds are arranged in two rows for each unit.

[0026] The cup s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com