Hardening method of steel member

A technology of steel components and quenching temperature, which is applied in the field of quenching of steel components, can solve problems such as large heat treatment deformation of steel components, and achieve the effects of reducing uneven heating, shortening heating time, and reducing uneven cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

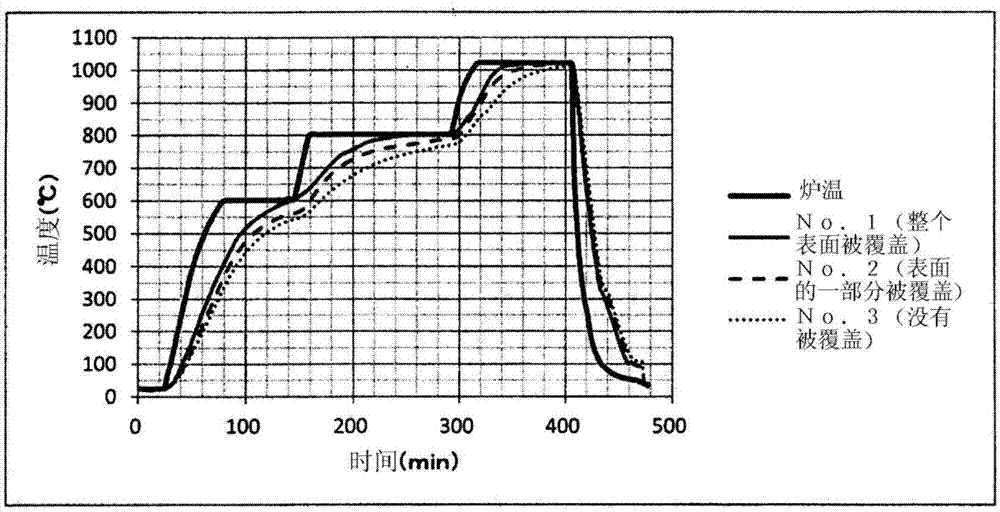

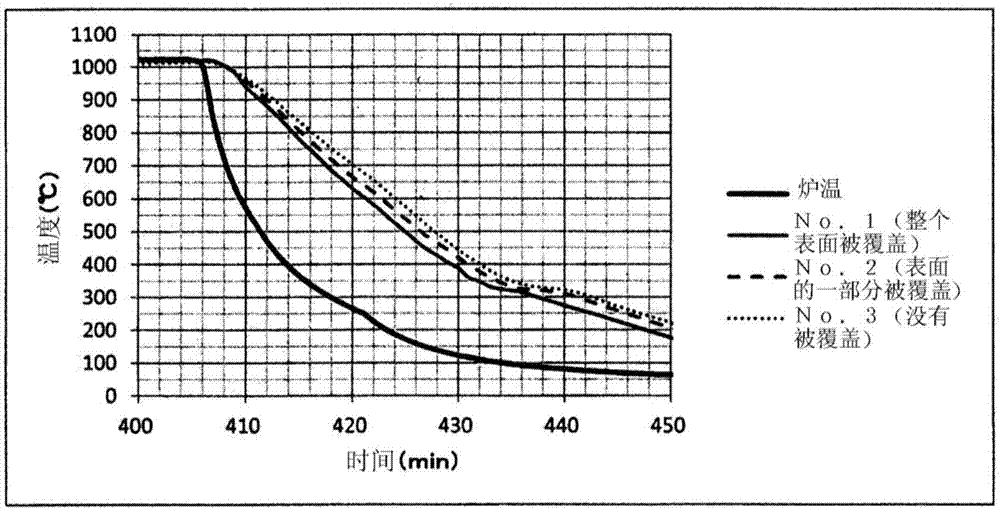

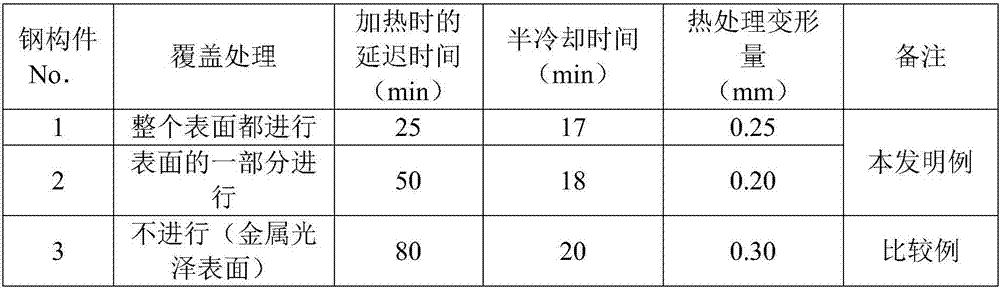

[0038] 150mm of thermal processing tool steel of SKD61 of the JIS standard 3 block widget. It is then milled on all sides to give it a metallic luster as a steel component for hardening. Next, a well-known anti-reflection agent for laser processing (product name: Black Guard Spray [Fain Chemical]) containing graphite fine powder is evenly sprayed on part or all of the surface of these steel members to the extent that no color spots can be detected visually. Japan Co., Ltd.]), which was coated and covered. Covering conditions are shown in Table 1, and there are the following two conditions: Coating all surfaces of the block member (No.1); leaving the opposite two surfaces, and forming a circular shape at the center of the remaining four sides. shape (radius 75 mm) for coating (No. 2).

[0039] Next, the infrared radiance at 200° C. was measured for the surface of the steel member which was subjected to the above-mentioned coating treatment and the surface which was not subje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com