Tunnel structure with foam concrete primary lining as damping layer

A foam concrete and tunnel structure technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as shock-absorbing materials and shock-absorbing measures that have not been proposed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

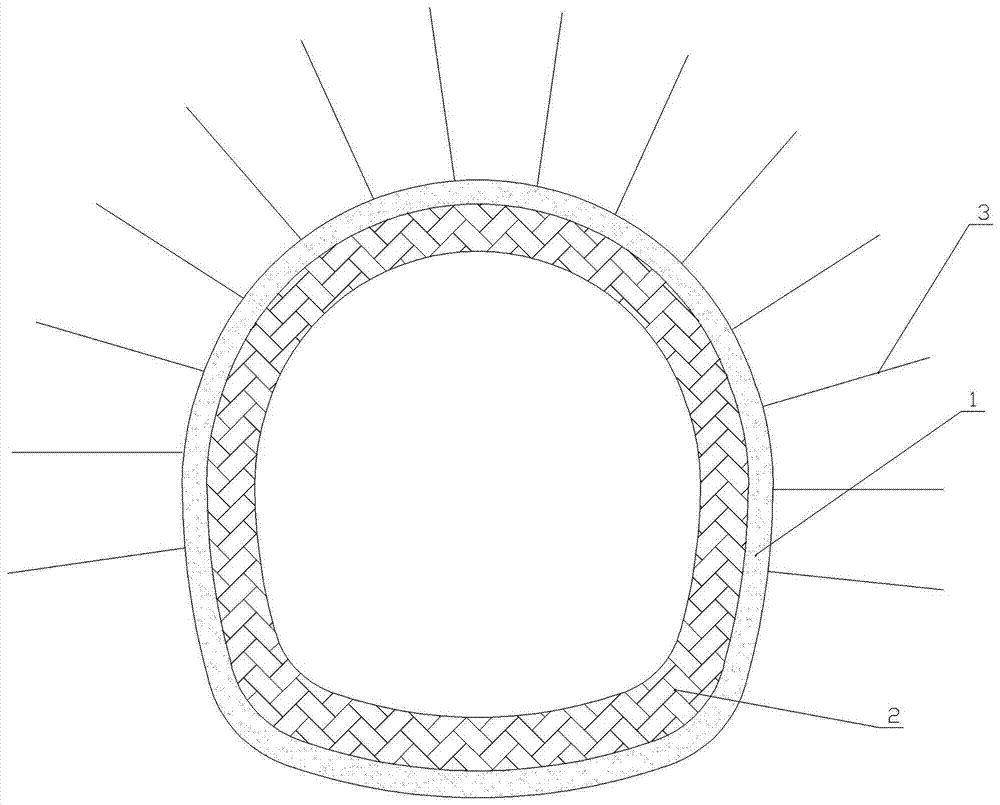

[0025] Such as figure 1 As shown, the tunnel structure of the foam concrete primary lining and shock-absorbing layer provided in this embodiment includes primary lining 1 and secondary lining layer 2, anchor rod 3 is placed on the primary lining 1, and the primary lining adopts compressive The foam concrete with a strength greater than 20MPa is sprayed, and the thickness of the primary lining is between 15-20cm.

[0026] The proportion of this foam concrete is: 600kg / m 3 , water 250kg / m 3 , foam 0.8 m 3 / m 3 , waterproofing agent 5 kg / m 3 , water reducer 6.5kg / m 3 , Antifreeze 13 kg / m 3 , fiber 1kg / m 3 , coagulant 30kg / m 3 And perlite 108kg / m 3 .

[0027] The production process of the foam concrete is as follows: ① use a foaming machine to make foam → ② mix various raw materials and stir evenly → ③ add fully foamed foam → ④ mix evenly and stir → ⑤ pouring molding → ⑥ curing.

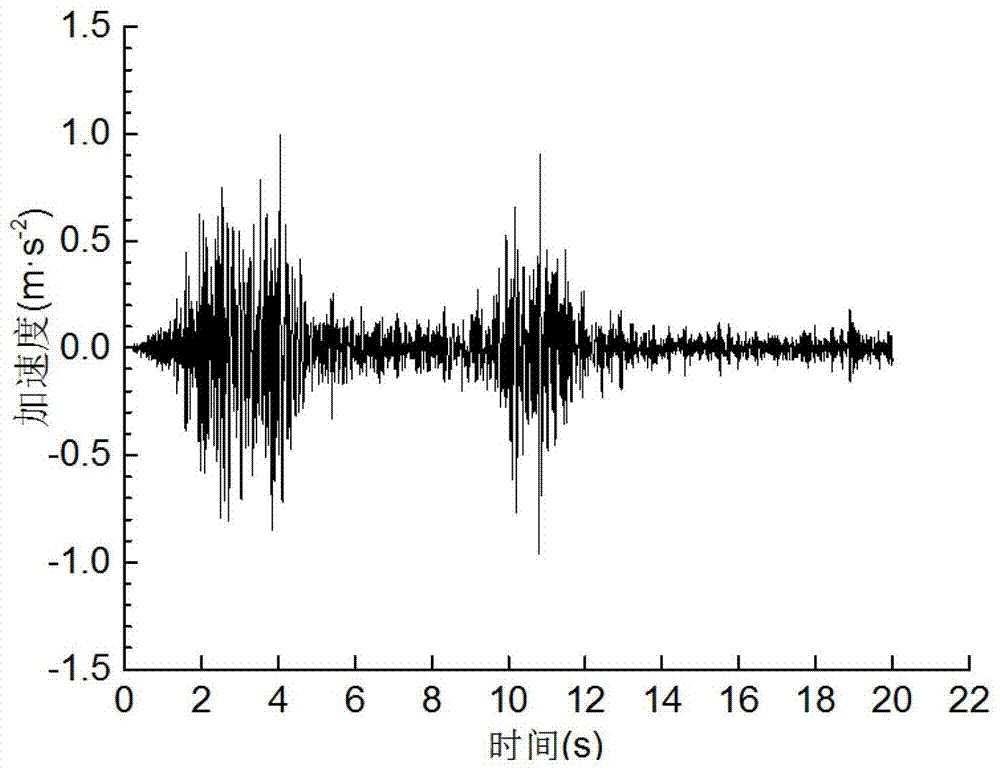

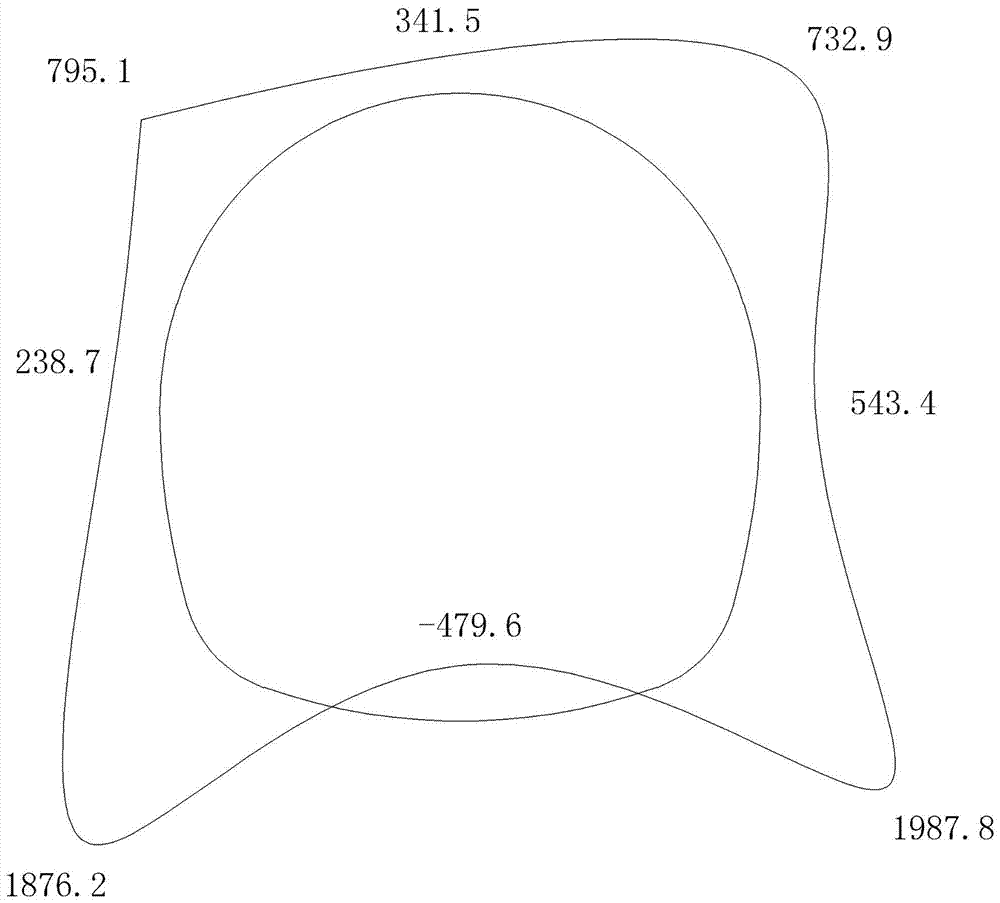

[0028] In the actual application process, after the construction and excavation of a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com