Multi-stage inner pipe freeze-proofing system, freeze-proofing heat exchanger and application

An antifreeze system and heat exchanger technology, applied in damage protection, heat exchange equipment, evaporators/condensers, etc., can solve the problems of high cost of antifreeze, large pollution, inability to power off operation, etc., and achieve good chemical stability and thermal stability, good safety and stability, good air tightness and water tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

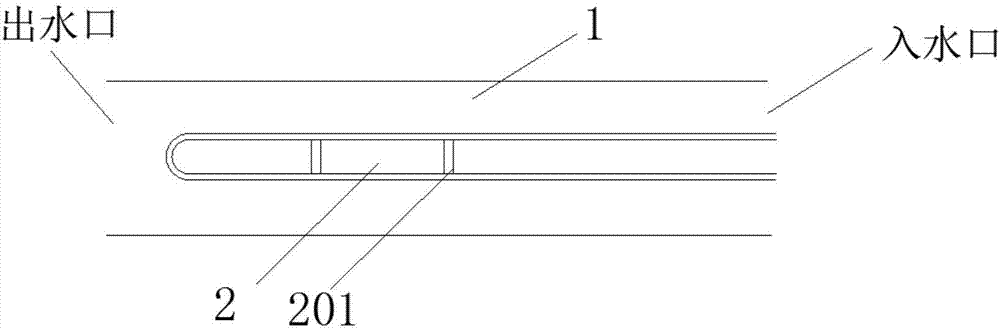

[0036] Such as figure 1As shown, a multi-stage inner tube antifreeze system includes an outer tube 1, an inner tube 2 is arranged inside the outer tube 1, and the inner tube 2 is a hollow elastic tube. The inner tube 2 is provided with one or more partitions 201. The hollow part of the elastic tube is isolated from the external liquid through the tube wall. If the external is water, the external water will not enter the internal hollow due to the water isolation effect of the elastic tube. part, to ensure the space of the hollow part, the setting of the partition 201 makes the inner pipe set to several hollow parts, when a part is broken or damaged, the remaining hollow parts can play the role of offsetting the expansion volume of freezing, which is safe it is good.

[0037] The elastic hose here can be a hose, and the inner pipe 2 is convenient to penetrate into the outer pipe 1. Of course, other types of elastic pipes can meet the requirements according to the requirements....

Embodiment 2

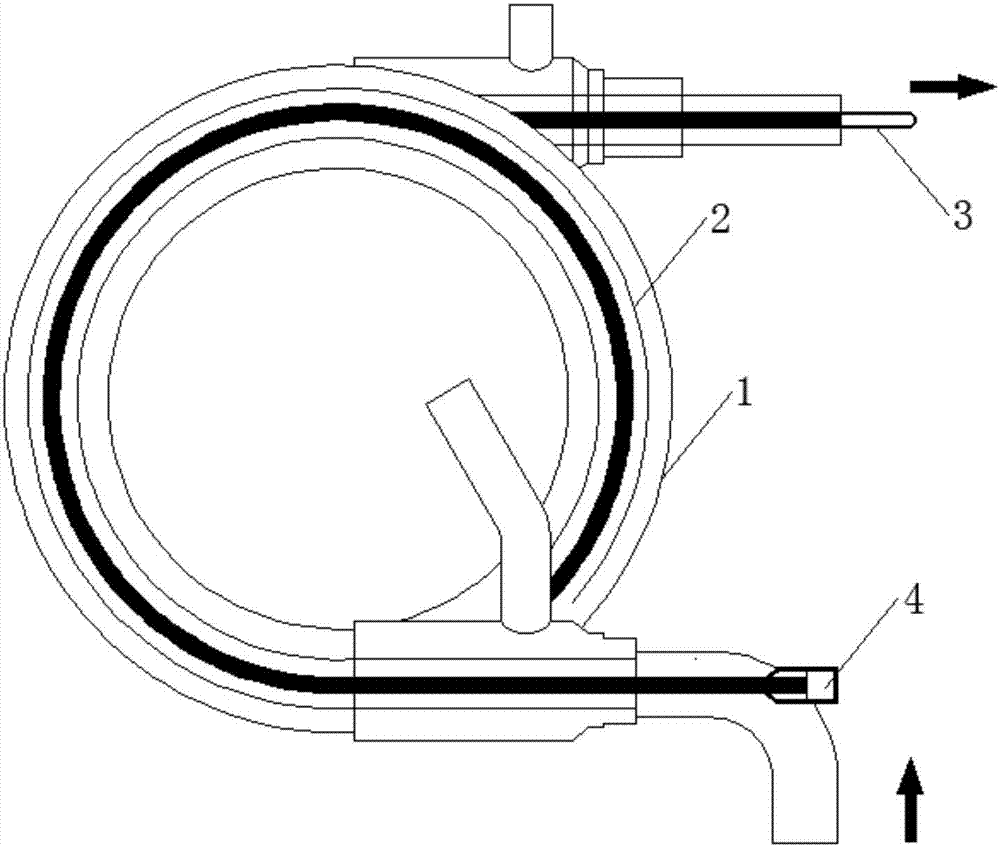

[0042] Heat exchangers are generally used for refrigerants and water in heat pump or air-conditioning fields. When the temperature is low during defrosting, refrigeration and winter, the water side of the heat exchanger may expand due to water freezing and cause the heat exchanger to freeze and damage. Add air-filled silicone or compressible pearl cotton tubes and other similar materials inside the heat exchanger. When the inside of the water side of the heat exchanger expands due to freezing volume, it can compress the air-filled silicone tube or pearl cotton tube and other similar materials. Reduce the pressure on the water side of the heat exchanger to prevent the heat exchanger from bursting.

[0043] The above-mentioned antifreeze system is used in the field of heat exchangers, such as figure 2 As shown, the casing heat exchanger composed of concentric inner tube and outer tube, this is the outer tube 1, and the outer tube 1 is provided with a sealed and compressible ho...

Embodiment 3

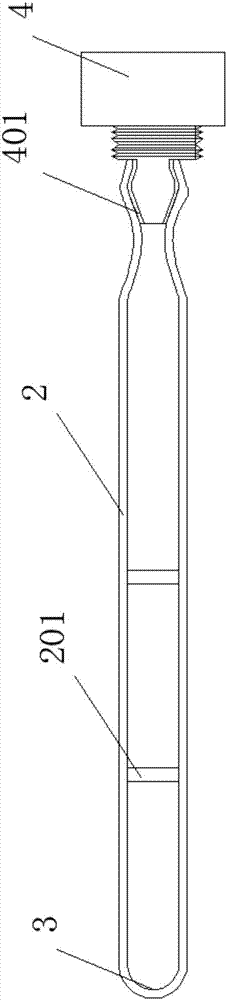

[0047] Embodiment 3 is basically the same as Embodiment 2, the difference is that, as image 3 As shown, the fixed joint 4 includes a connection port 401, the inner tube 2 is sleeved on the connection port 401, the middle of the connection port 401 is connected, and the connected connection port 401 communicates the hollow space of the inner tube 2 near the connection port 401 with the outside atmosphere . When working, under normal circumstances, the inner pipe 2 is kept hollow due to the low water pressure and the inner pipe 2 due to the certain strength of the pipe. The hollow air in the hollow space near the connection port 401 communicates with the external air. When the temperature drops, When the water in the pipe freezes, the volume of the water increases due to freezing, and the increased volume squeezes the inner pipe 2, and the air in the inner pipe 2 is discharged into the atmosphere through the hollow port of the connection port 401, and the inner pipe 2 shrinks, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com