Vertical dual adjustment device of mining laser orientation instrument

A technology of vertical adjustment and laser pointing, which is applied to active optical measuring devices, measuring devices, instruments, etc., can solve the problems of inconvenient adjustment of the vertical position of the laser pointing device, time-consuming and laborious, etc., and achieves convenient and fast vertical adjustment, low price, and easy to use. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

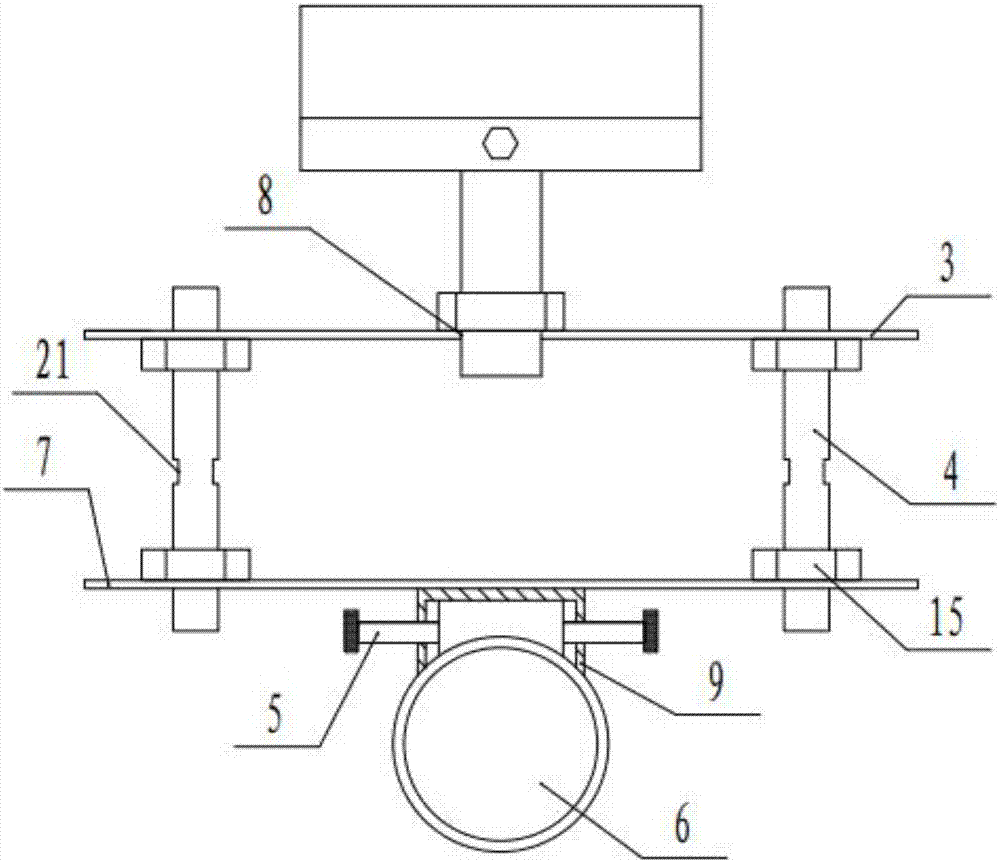

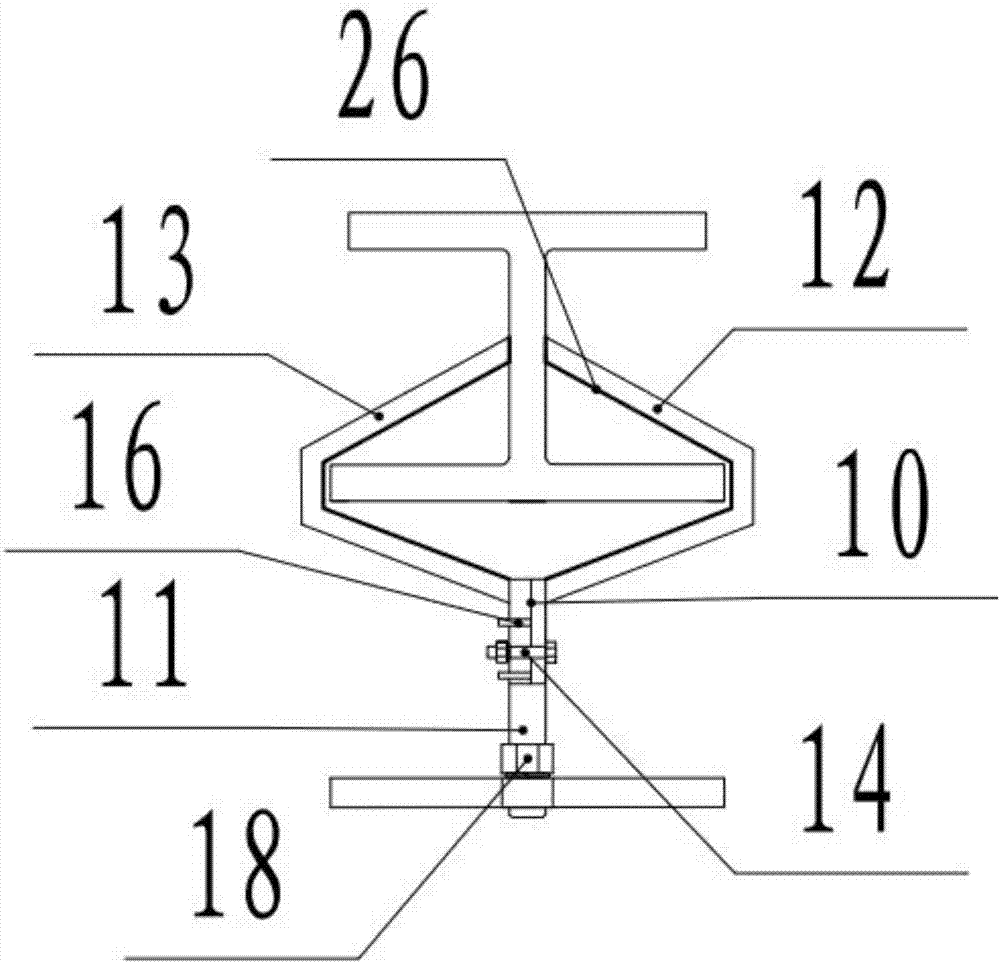

[0018] Example 1: Such as Figure 1-Figure 5 As shown, a vertical dual adjustment device for a mining laser pointer includes a fixing clamp 2, an upper vertical adjustment plate 3, a vertical adjustment screw 4, and a lower vertical adjustment plate 7. The lower end of the fixing clamp 2 is provided with a connecting screw 11, and the connecting screw The lower end of 11 is connected to the threaded hole 8 in the middle of the upper vertical adjusting plate 3, and the four corners of the vertical adjusting plate 3 are connected to the lower vertical adjusting plate 7 by vertical adjusting screws 4.

[0019] Preferably, the vertical adjustment screw 4 is provided with a fastening nut 15 for fastening the upper vertical adjustment plate 3 and the lower vertical adjustment plate 3.

[0020] Preferably, the connecting screw 11 is further provided with a lock nut 18 and a spring washer for locking the upper vertical adjustment plate 3.

[0021] Preferably, a bubble level 20 is provided o...

Embodiment 2

[0023] Example 2: Such as Figure 1-Figure 5 As shown, a mining laser pointer includes a mine I-beam 1, a fixing clip 2, a laser pointer body 6, and the laser pointer body 6 is connected to the fixing clip through a horizontal and vertical position adjustment mechanism 2. The fixing clamp 2 is fixed and clamped to the I-beam 1. The I-beam 1 is installed on the top of the mine perpendicular to the length of the mine. The laser emitting head of the laser pointer body 6 faces the length of the mine. The mine I-beam is 11# I-beam, the horizontal and vertical position adjustment mechanism is used to adjust the light spot to coincide with the middle waist line of the roadway in the vertical direction and to adjust the light spot to coincide with the middle waist line of the roadway in the horizontal direction.

[0024] Preferably, the above-mentioned horizontal and vertical position adjustment mechanism includes an upper vertical adjustment plate 3, a vertical adjustment screw 4, a low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com