Device for monitoring Hall effect thruster plume region product components

A Hall thruster and plume technology is applied in the field of monitoring the product components of Hall thrusters, which can solve problems such as spacecraft corrosion, charge accumulation, and communication influence, and achieve the effect of avoiding interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

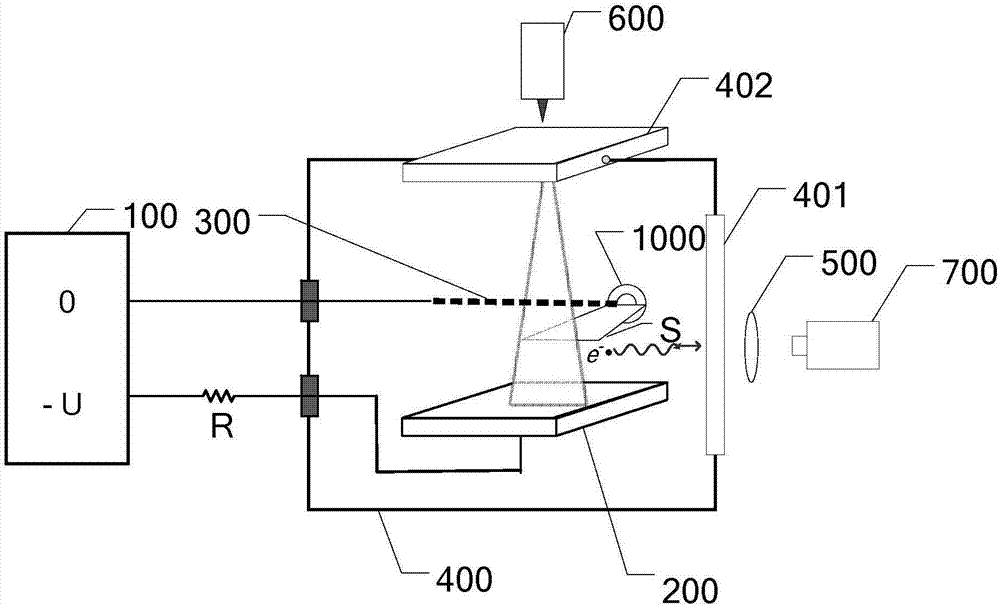

[0021] Specific implementation mode one: combine figure 1 Specifically explain this embodiment, a device for monitoring product components in the plume area of a Hall thruster, including a high-voltage power supply 100, a cathode plate 200, an electrode 300, a vacuum chamber 400, a filter 500, a nanosecond pulse laser 600, and an ICCD camera 700 and computer 800;

[0022] The cathode plate 200 is opposite to the electrode 300 and arranged in parallel in the vacuum chamber 400. The plume area of the Hall thruster is located in the area between the cathode plate 200 and the electrode 300. The bias voltage output terminal of the high voltage power supply 100 is connected to The cathode plate 200, the zero-potential output terminal of the high-voltage power supply 100 is connected to the electrode 300;

[0023] The laser light emitted by the nanosecond pulse laser 600 passes through the second window 402 and is vertically incident on the cathode plate 200. The jet direction o...

specific Embodiment approach 2

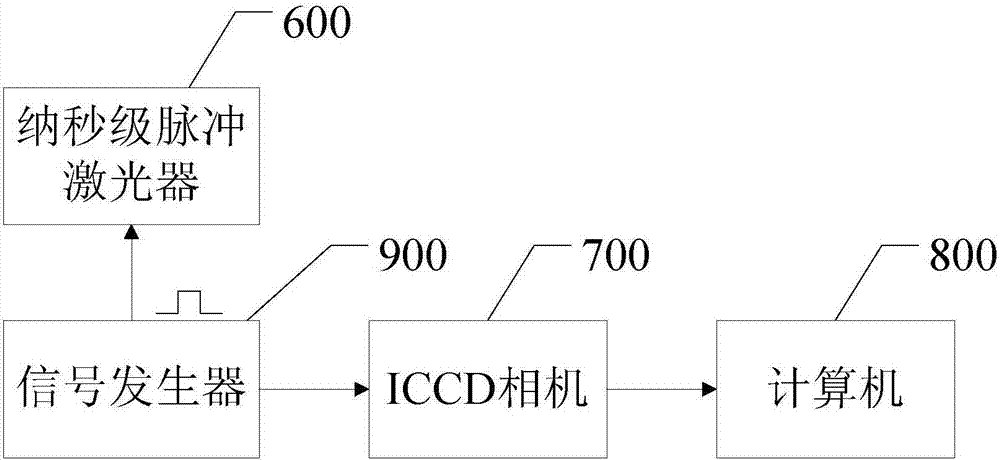

[0028] Specific implementation mode two: combination figure 2 This embodiment is described in detail. This embodiment is a further description of the device for monitoring the product components in the plume area of the Hall thruster described in the first embodiment. In this embodiment, in this embodiment, the signal Generator 900 , the rectangular signal output by the signal generator 900 triggers the nanosecond pulse laser 600 and the ICCD camera 700 synchronously.

[0029] ICCD camera and laser are controlled by the same signal generator. The signal generator produces a rectangular wave with a frequency of 100-1000Hz. The rectangular signal generated by the signal generator is input to the solid-state laser and ICCD, and the laser and ICCD are synchronously triggered to work. The fluorescent signal captured by ICCD is input into the computer and saved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com