Lawn cropper

A lawn trimmer and motor shaft technology are used in lawn trimming. It can solve the problems of high noise of gasoline and diesel engines, large pollution of gasoline and diesel engines, troublesome structure and operation, etc., and achieve the effects of reliable stability, energy saving and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

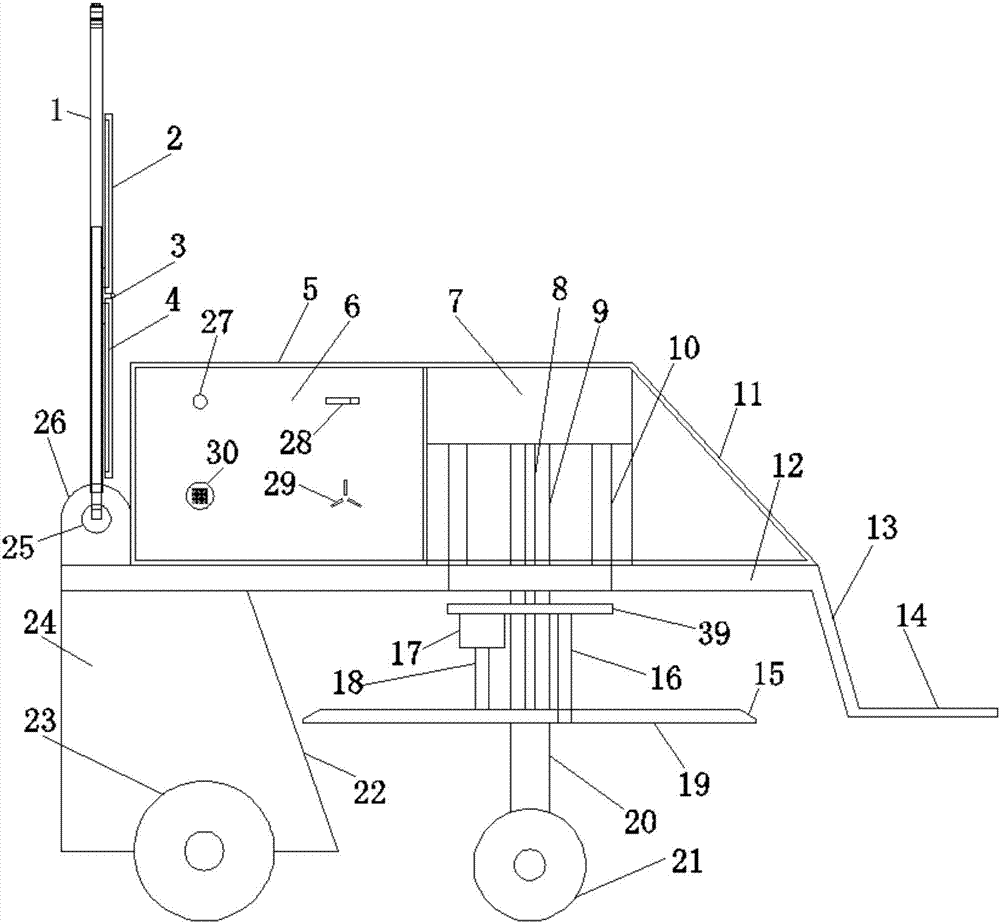

[0042] Such as Figure 1-8 As shown, it shows a specific embodiment of the present invention, as shown in the figure, a lawn trimmer disclosed by the present invention includes a platform 12, a horizontal rake 14 is installed at the front end of the platform 12, and a protective shell is installed on the surface of the platform 5. A battery 6 and a motor 7 are installed in the protective case; the motor shaft 9 of the motor 7 is vertically downward, and the motor shaft 9 extends to the bottom of the platform, and a cutter head 19 is installed on the part of the motor shaft below the platform, and the cutter head 19 is equipped with blades 194 for mowing lawns;

[0043] The bottom end of the motor shaft is connected with the front travel wheel 21 (in this embodiment, the front travel wheel is a universal wheel, which can turn flexibly) through an extension column, and the extension column is installed on the bottom of the motor shaft through a bearing rotation. Therefore, when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com