Microfluidic integration device with adjustable and controllable throughput and manufacturing method thereof

An integrated device and microfluidic technology, which is applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problems that a single chip cannot be processed, the processing throughput of the chip is small, and the product is not perfect. Achieve the effect of low chip production cost, simple structure and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

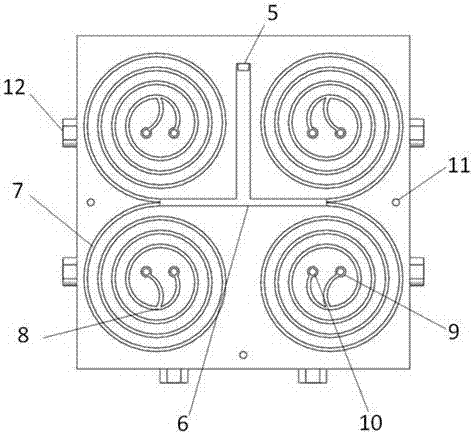

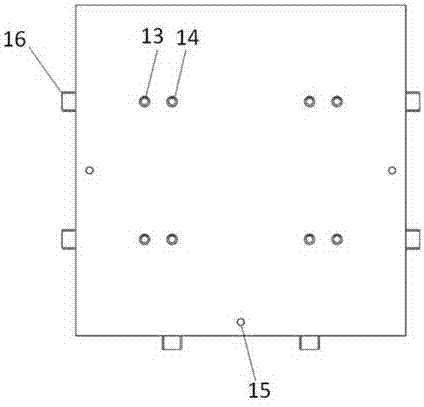

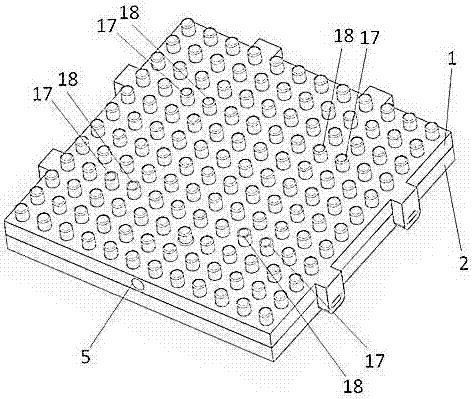

[0028] The invention provides a microfluidic device based on a Lego model with adjustable processing flux and a high-throughput concentration of micron-sized particles and a manufacturing method thereof, which is achieved by using a plurality of Lego modules to stack vertically and concentrating samples at the same time. High-throughput processing requirements and the purpose of free regulation of processing flux.

[0029] The flow distribution module and the bottom current collection module of this embodiment are manufactured using translucent resin as a raw material by 3D printing technology. Due to the narrow spiral flow channel of the functional module, the direct printing accuracy may not be enough, and it is easy to be deformed and blocked, so it needs to be realized by micro-machining technology. The main body of the microfluidic chip in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com