Cleaning method of battery plate head

A technology for battery pole plates and plate heads, which is applied in the field of cleaning the plate heads of battery plates, can solve the problems of complicated cleaning procedures, high labor costs, and thin plate head thickness, and achieves convenient cleaning procedures, low labor costs, and consistent cleanliness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a more complete and clear disclosure of the technical content used in the present invention, the purpose of the invention and the effects achieved, it will be described in detail below, and please also refer to the disclosed drawings and drawing numbers:

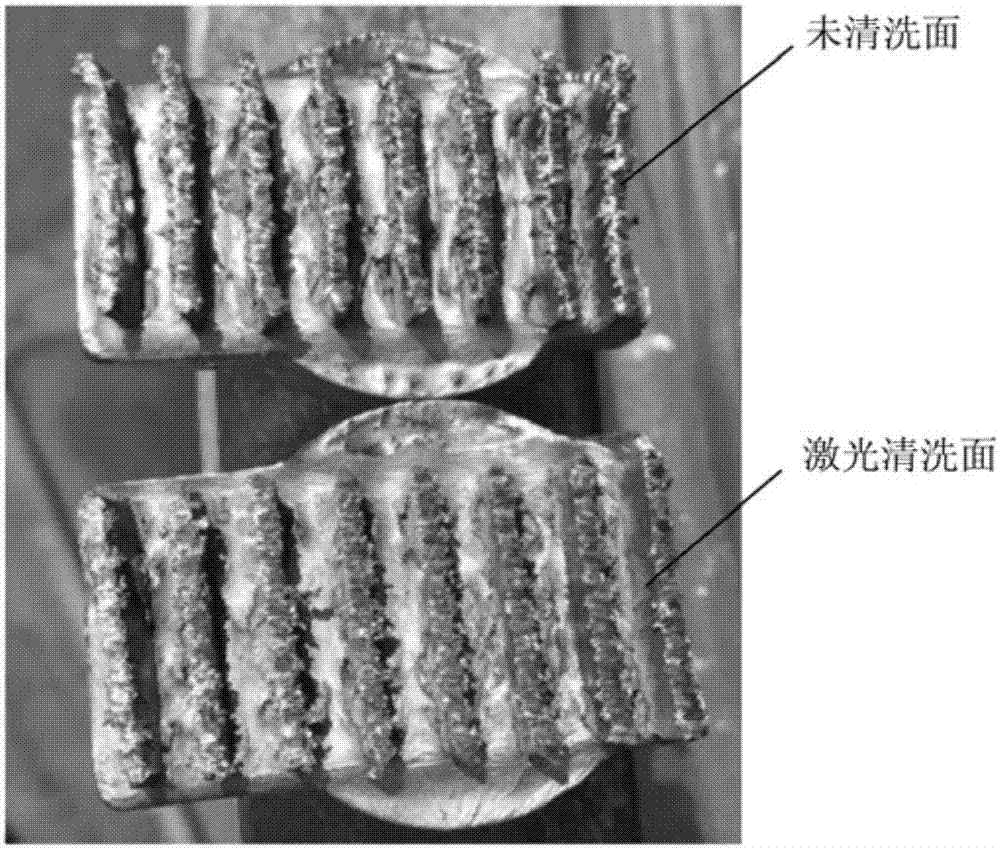

[0034] The method for cleaning the plate head of the battery pole plate of the present invention is mainly to carry out the cleaning step of the plate head before the plate head of the battery pole plate is welded by lead bridge, so that the plate head can reduce the dirt or surface attached to the surface after cleaning. The oxides and dust generated are beneficial to the combination with the lead bridge and the head, and avoid the gaps generated during the welding process of the lead bridge due to the dirt on the surface or the oxides and dust generated on the surface, which will lead to the conduction of heat and energy The problem of falling coefficients.

[0035] The method for cleaning the plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com