Apparatus for producing TPU (thermoplastic polyurethane) leather

A technology of equipment and pressing device, which is applied in the field of equipment for producing TPU leather, can solve problems such as low degree of automation, failure to be discovered in time, and impact on continuous production, so as to improve heat conduction efficiency, reduce production cost, and reduce raw material loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

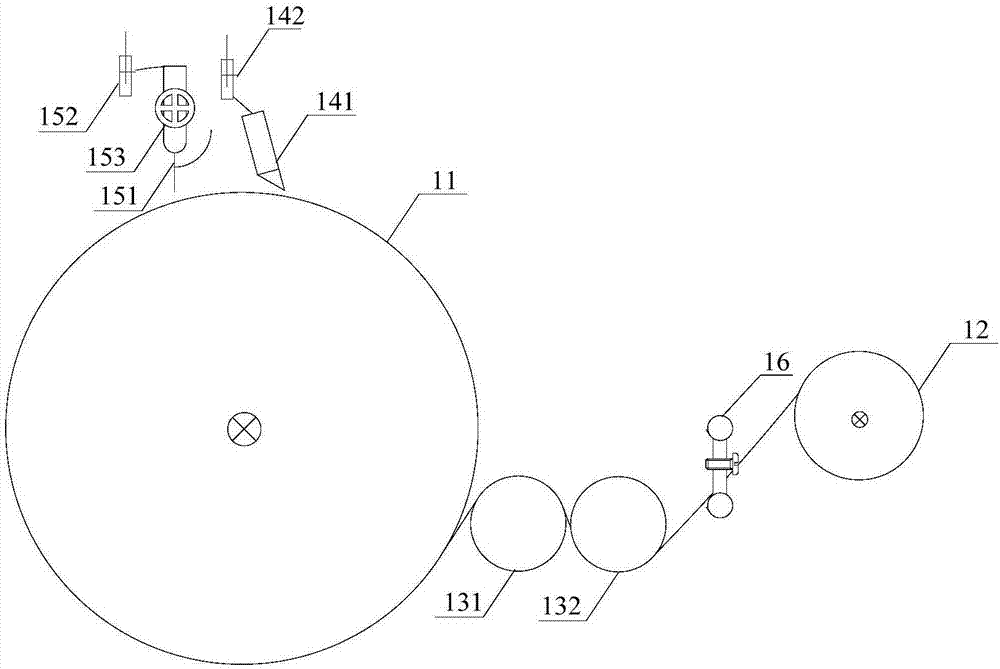

[0031] A kind of equipment for producing TPU leather, such as figure 1 As shown, wherein, a heating wheel 11 with a flatness of 0.05 μm, a scraper 141 connected to a first elevator 142, a hot melt adhesive guiding device 151 connected to a second elevator 152, and a hot melt adhesive measuring controller 153 constitute a coating The cloth device, the pressing wheel 131 and the pressing wheel 132 constitute the pressing device, the TPU discharge wheel 12 is arranged on the upper right of the pressing wheel 131 and the pressing wheel 132, and the tension controller 16 is arranged on the pressing wheel and the TPU discharging Between round 12.

[0032]The process of producing TPU leather using the device of Example 1: adjust the distance between the hot melt adhesive guiding device 151 and the heating wheel 11 through the second elevator 152, adjust the height of the scraper 141 through the first elevator 142 to ensure that the scraper 141 and the heating wheel 11 The distance b...

Embodiment 2

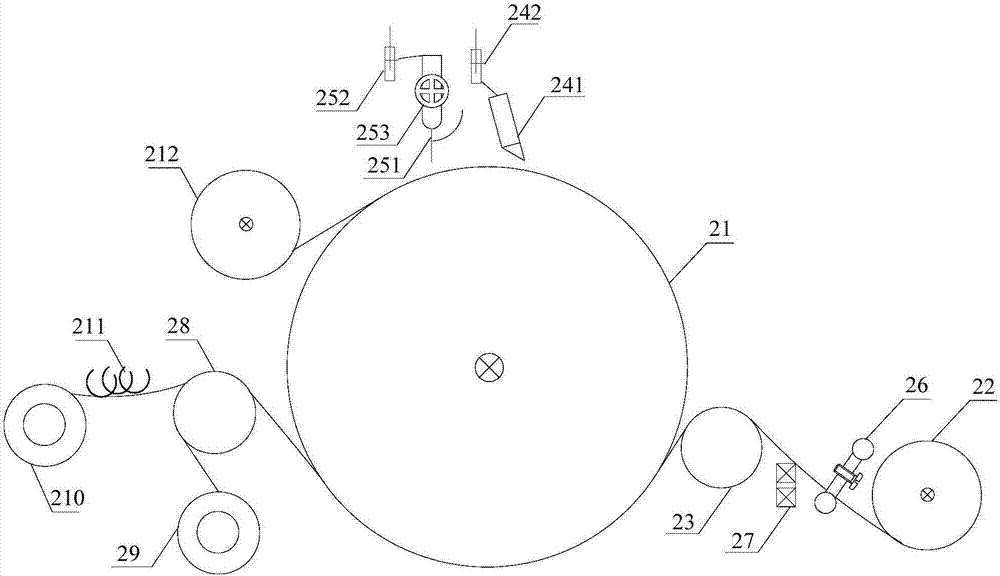

[0035] A kind of equipment for producing TPU leather, such as figure 2 As shown, wherein, the heating wheel 21, the scraper 241 connected with the first elevator 242, the hot melt adhesive guiding device 251 connected with the second elevator 252, and the hot melt adhesive weighing controller 253 form a coating device, and the pressing wheel 23 and The heating wheel 21 constitutes a pressing device, the peeling paper discharge wheel 212 is arranged on the upper left side of the heating wheel 21, the TPU discharging wheel 22 is arranged on the right side of the pressing wheel 23, between the pressing wheel 23 and the TPU discharging wheel 22 A deviation corrector 27 and a tension controller 26 are sequentially arranged from left to right, and a cooling and setting wheel 28 , a TPU leather winding wheel 29 , an antistatic device 211 and a release paper winding wheel 210 are successively arranged on the left side of the heating wheel 21 .

[0036] The process of producing TPU le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap