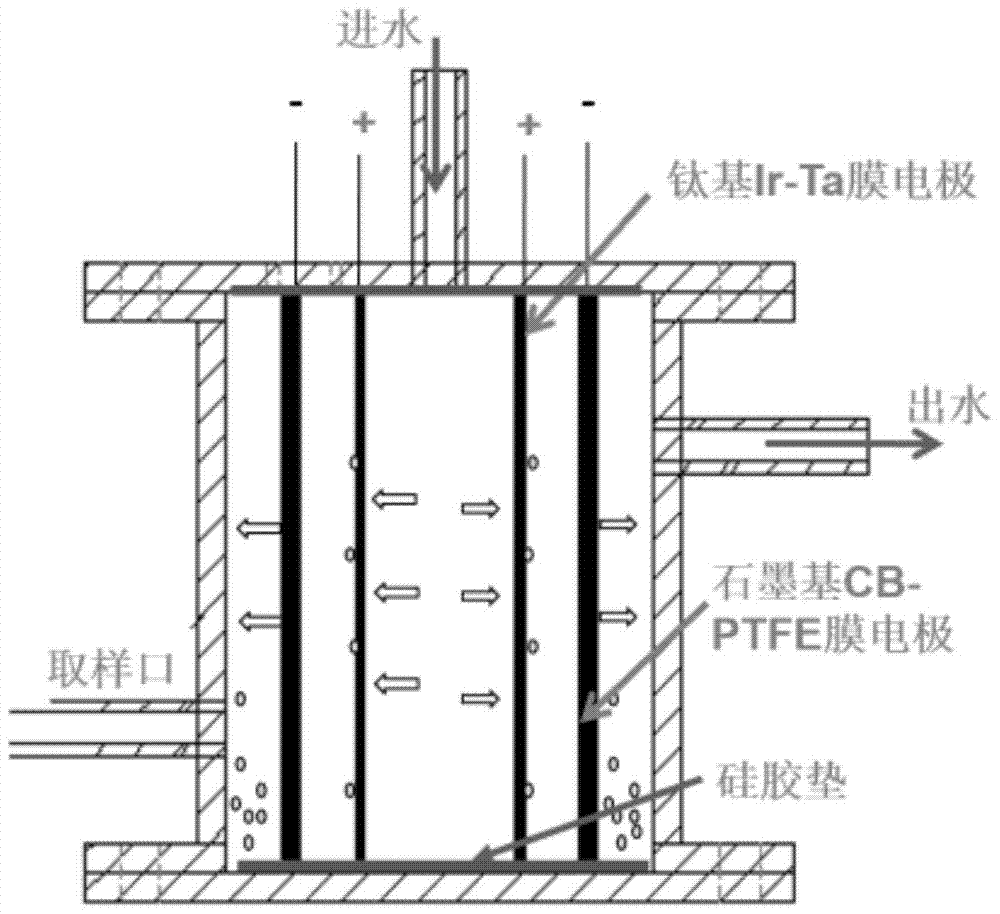

Double tubular membrane electrode electro-catalytic reactor

An electrocatalysis and reactor technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor utilization of oxygen and poor mass transfer effect of surface pollutants , low oxygen utilization efficiency and other issues, to achieve the effect of improving electrocatalytic performance, more active sites, and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

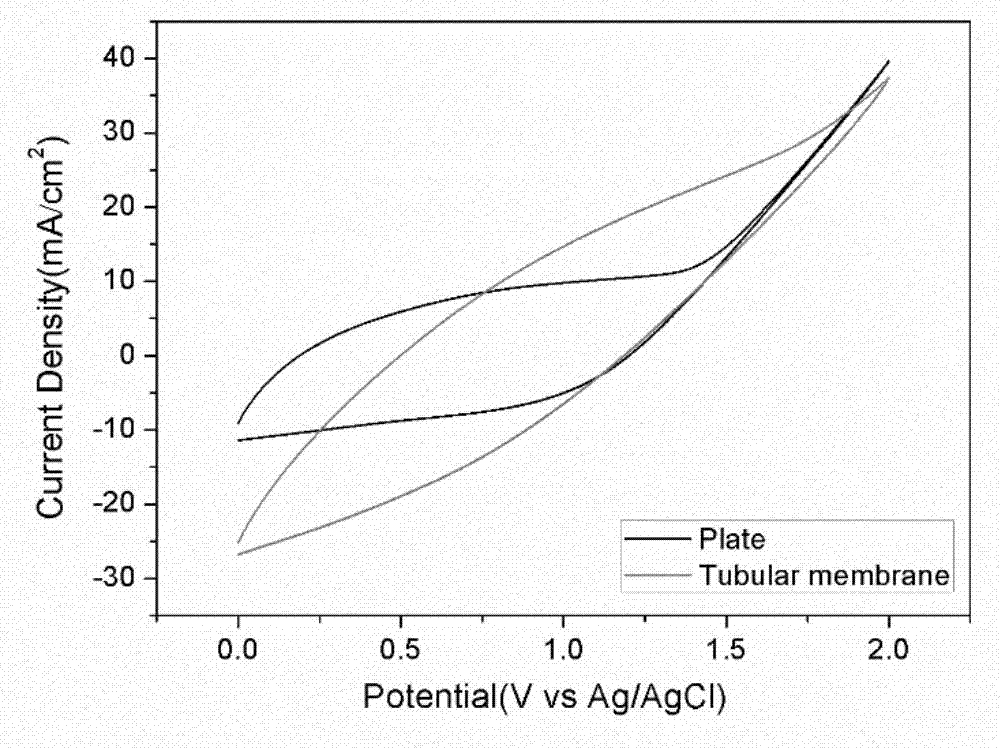

[0041] The tubular titanium-based membrane with a size of Φ30×1.5×30mm was ultrasonically cleaned with 20% sodium hydroxide to remove surface oil; then heated in 10% oxalic acid solution for 2 hours to remove the oxide layer; finally stored in 1% oxalic acid solution for future use. Prepare 0.108mol / L chloroiridic acid and 0.092mol / L tantalum pentachloride isobutanol solution, adjust to pH=2 with concentrated hydrochloric acid, and evenly brush the brushing solution onto the pretreated tubular titanium-based film, Put it in an oven for 15 minutes, take it out and put it into a muffle furnace, raise the temperature to 450°C at a rate of 1°C / min, and bake for 10 minutes. The above operation is repeated 10 times, and the last time is baked in a muffle furnace for 60 minutes.

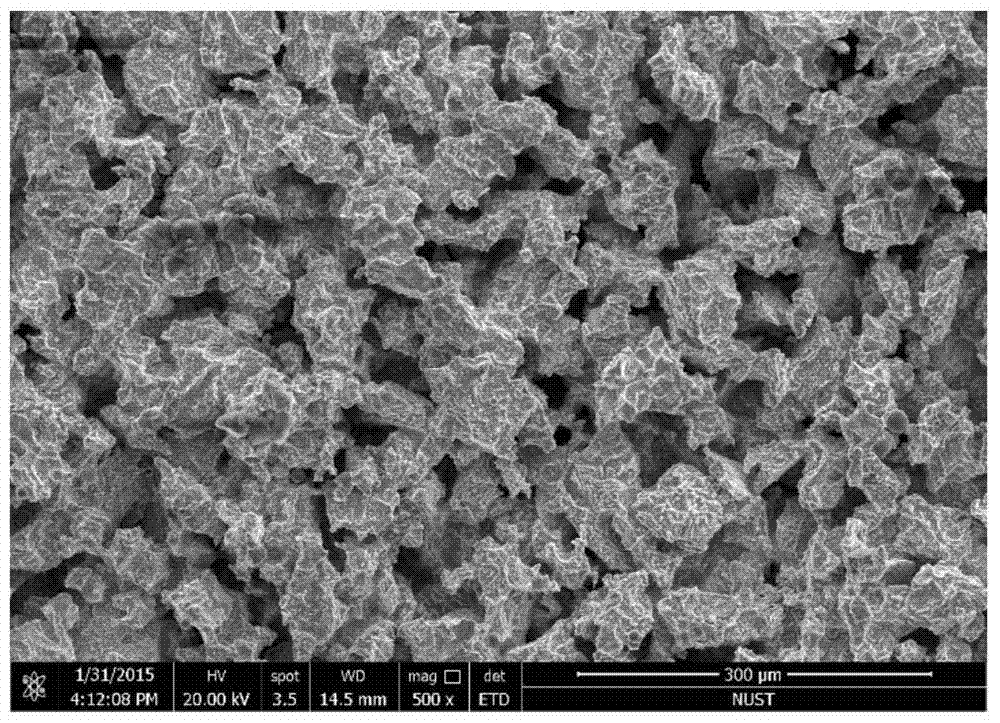

[0042] The tubular graphite-based membrane with a size of Φ55×2.5×30mm was ultrasonically cleaned with acetone for 2 hours to remove surface oil; then ultrasonically cleaned with ethanol and deionized water ...

Embodiment 2

[0048] The pretreatment process of the tubular titanium-based membrane is the same as that of Example 1. Prepare 0.095mol / L chloroiridic acid and 0.081mol / L tantalum pentachloride isobutanol solution, adjust to pH=3 with concentrated hydrochloric acid, and evenly brush the brushing solution onto the pretreated tubular titanium-based film, Put it in an oven for 10 minutes, take it out and put it into a muffle furnace, raise the temperature to 500°C at a rate of 2°C / min, and bake for 10 minutes. The above operation is repeated 15 times, and the last time is baked in a muffle furnace for 60 minutes.

[0049] The pretreatment process of the tubular titanium-based membrane is the same as that of Example 1. Prepare 1% carbon black, 1.2% polytetrafluoroethylene emulsion, and 2.5% n-butanol aqueous solution, put the pretreated tubular graphite-based film into the prepared solution and ultrasonically 6h until uniform dispersion, and put it in a 60-degree oven to dry After 18 hours, ta...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap