A working control method of a suction pump and a washing machine

A technology for work control and suction pump, applied in the field of washing machines, can solve the problems of time-consuming and electricity consumption, loss of service life of suction pump, long operation time of suction pump, etc., and achieve the effect of saving time and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

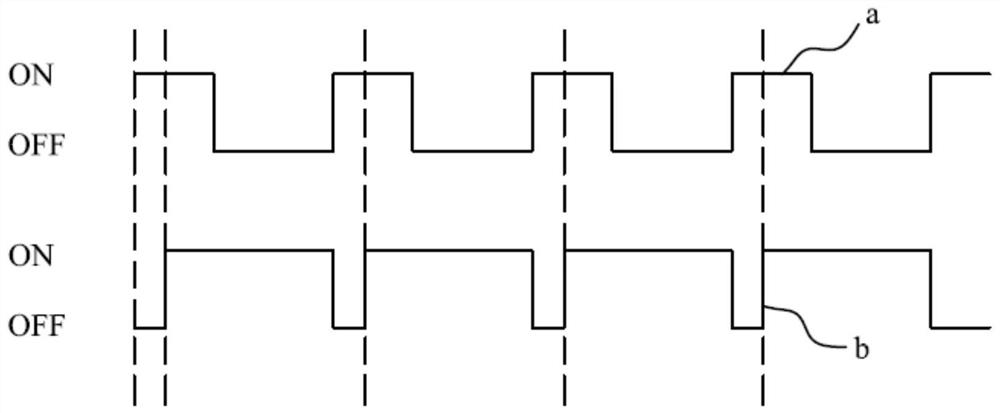

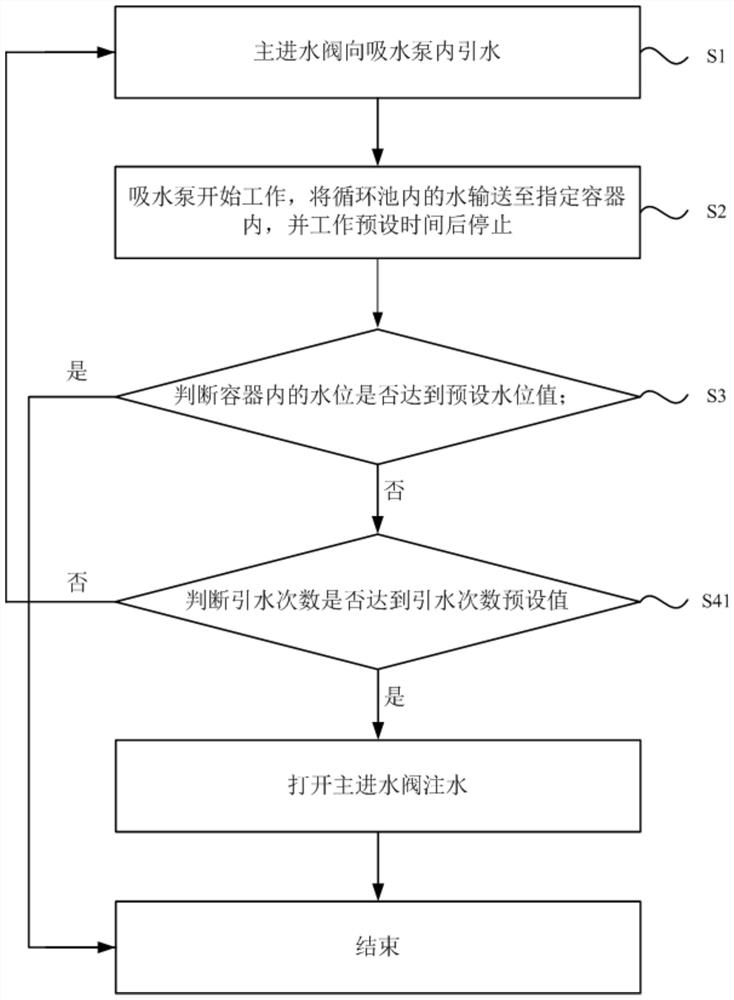

[0031] as Figure 1 and Figure 2 As shown in the present embodiment, the present embodiment provides a working control method for suction pumps, comprising:

[0032] S1: The main inlet valve diverts water to the suction pump;

[0033] S2: The suction pump starts working, transports the water in the circulating pool to the specified container, and stops after working for a preset time;

[0034] S3: Determine whether the water level in the container reaches the preset water level value;

[0035] S4: If the water level does not reach the preset water level value, repeat Steps S1-Step S3; If the water level reaches the preset water level value, the work stops.

[0036] The control method in the present embodiment reduces the continuous working time of the suction pump by presetting the working time of the suction pump, and sets the suction pump to work at intervals, effectively avoiding the long-term working loss of the suction pump Life; In addition, each time the suction pump stops w...

Embodiment 2

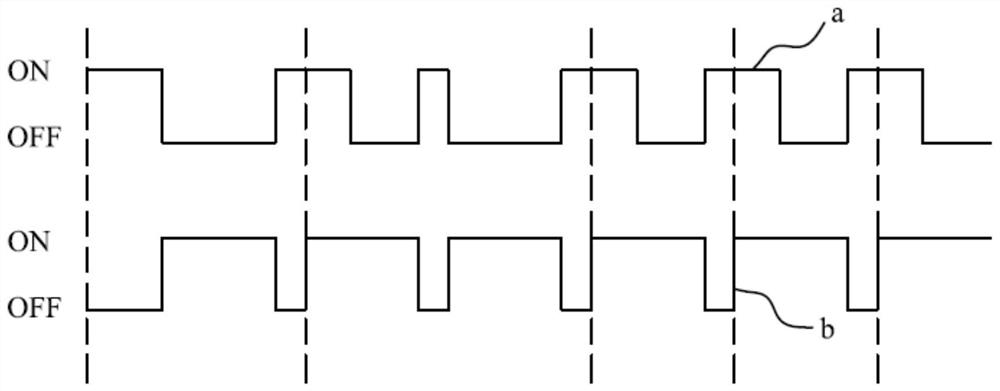

[0046] as Figure 3 As shown, the present embodiment provides a working control method of the suction pump, substantially the same as the control method in Example 1, different from Example 1, the time of the first introduction of water to the suction pump is greater than the time after the introduction of water into the suction pump.

[0047] The present embodiment is applied to the washing machine as an example in detail. Some of the existing washing machines have added a softener box, the first time to the suction pump when the water is diverted, it is through the main inlet valve to the suction pump to inject water, and flow through the washing box containing laundry detergent or washing powder in the washing machine, the laundry detergent or washing powder is flushed into the laundry bucket, in order to avoid the washing liquid or washing powder is not rinsed, resulting in the residual foam due to the suction pump working at the same time to the suction pump when the water flo...

Embodiment 3

[0052] The present embodiment provides a washing machine, comprising a control method in the above embodiment. The control method reduces the continuous working time of the suction pump by presetting the working time of the suction pump, and sets the suction pump to work at intervals, effectively avoiding the long-term working loss of the suction pump life of the suction pump; In addition, each time the suction pump stops working, the water level is judged, if the preset water level value is reached or the circulating water volume is insufficient, the suction pump can be stopped in time, saving time and energy consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com