A powder metallurgy brake disc and its production process

A technology of powder metallurgy and brake discs, which is applied in the field of brake discs, can solve the problems affecting the normal deceleration process of vehicles, reduce the heat dissipation function of brake discs, and reduce the service life of brake discs, etc., achieve standardization of size, improve cooling effect, and reduce self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

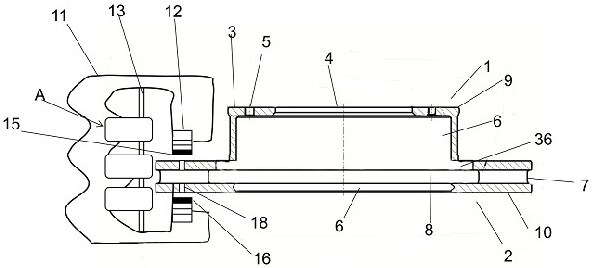

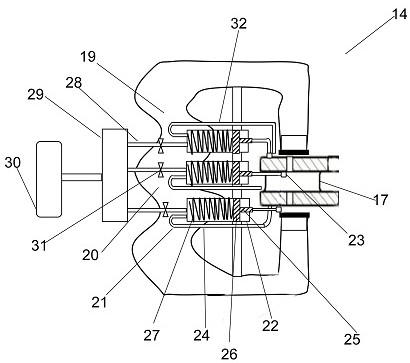

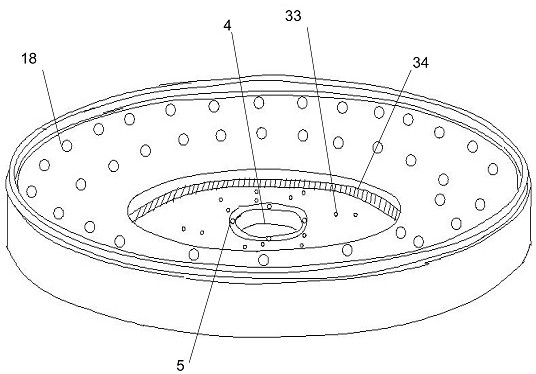

[0056] A powder metallurgy brake disc, comprising a brake disc body and a heat dissipation device 14, the brake disc body includes a first brake disc 1 and a second brake disc 2, the center of the first brake disc 1 is provided with a mounting surface 3, the mounting surface 3 is provided with a central hole 4, and the mounting surface 3 is uniformly provided with bolt holes 5 on the periphery of the central hole 4, and there are four bolt holes 5. The mounting surface 3 is connected to the first brake disc 1, and the mounting surface 3 and the There is a small space 6 between the first brake discs 1, a hollow 36 is provided at the center of the first brake disc 1, the outer side of the first brake disc 1 is the first braking surface 9, and the first braking surface 9 corresponds to the hollow 36 The position of the heat dissipation hole 33 is provided, and the heat dissipation hole 33 is uniformly arranged to dissipate the heat between the brake discs. The edge circumference o...

Embodiment 2

[0059] The raw material composition of brake disc body powder preparation is calculated by weight percentage: C: 2.8%; Si: 1%; Mn: 0.5%; S: 1.5%; P: 0.2%; Cu: 0.2%; Cr: 0.2%; V : 0.1%; N: 0.2%, Co: 4%; the rest is Fe.

[0060] The preparation of the brake disc comprises the following steps:

[0061] (1) Use a pulverizer to pulverize the raw materials of the brake disc to 80-100 mesh, configure the powder according to the above ratio, and use a ball mill to mix for 11 hours;

[0062] (2) Weighing the uniform raw material obtained in step (1) and adding it to a mould, using a 300t press to press-form the mixed powder to obtain a semi-finished brake disc;

[0063] (3) Heat the semi-finished brake disc in step (2) to 1100°C in an intermediate frequency induction furnace for sintering. The sintering time is 60 minutes, and the furnace temperature remains at 1100°C;

[0064] (4) Naturally cool the melted brake disc semi-finished product out of the furnace to normal temperature to ...

Embodiment 3

[0071] The raw material composition of brake disc body powder preparation is calculated by weight percentage: C: 3.6%; Si: 2%; Mn: 1.5%; S: 2.5%; P: 0.6%; Cu: 0.8%; Cr: 0.3%; V : 1%; N: 1.5%, Co: 8%; the rest is Fe, the preparation process is the same as in Example 3, and the mechanical performance of the brake disc is tested according to the method in Example 3, and the test result is: HRC70, and the tensile strength is: 450MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com