Temperature compensated beam resonator

一种谐振器、微机电谐振器的技术,应用在电气元件、阻抗网络等方向,达到高频率稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

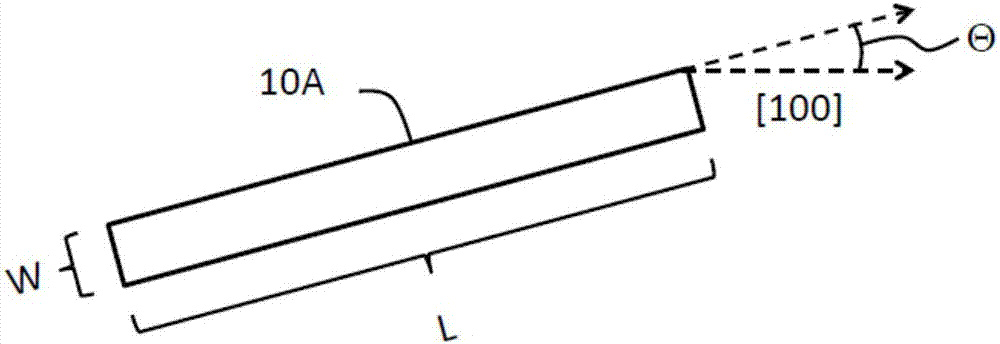

[0067] Figure 1A A resonator comprising a single beam 10A, with length L and width W, fabricated on a (100) wafer is shown. Beam 10A is tilted at an angle Θ with respect to the [100] crystal direction. Depending on the desired resonant mode to be excited, the inclined beam 10A may be anchored to a surrounding support structure (not shown) from an anchor point at one of its longitudinal ends or midway between one or both longitudinal sides. Preferably, the anchoring occurs at one or more nodes or quasi-nodes of the resonant modes at the perimeter of the beam 10A.

[0068] A disadvantage of the resonator of Figure 1A is that it is asymmetrical with respect to the [100] direction, whereby spurious resonant modes may be generated in the beam along with the main resonant mode. These spurious modes may degrade the quality factor of the resonator and may even affect the TCF characteristics of the main resonant mode.

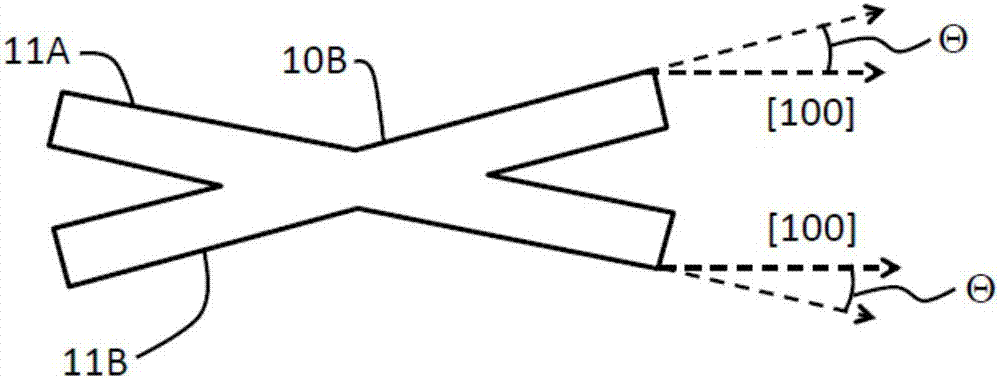

[0069] Figure 1B The resonator of , which avoids the disadva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com