Manufacturing method of heat treated vanilla extract

A vanilla extract and heat treatment technology, which is applied in the direction of food heat treatment, food ingredients containing natural extracts, food treatment, etc., can solve the problems of aroma, aroma maturity, and taste that cannot be said to be sufficient and cannot be adequately dealt with, etc. To achieve the effect of enhanced taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

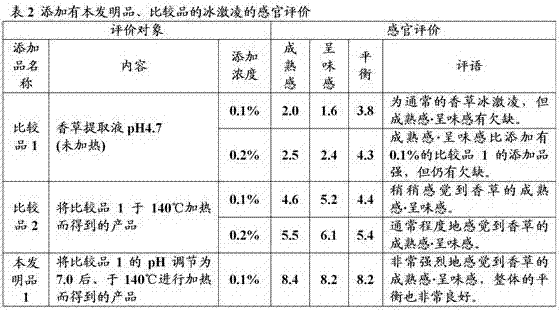

[0053] (Example 1) A product obtained by adding sugar to a vanilla extract extracted with ethanol and heating it (non-concentrated type, no enzyme reaction)

[0054] (1) Preparation method

[0055] Mix 2000g of soft water and 2000g of 95% ethanol, put in 500g of vanilla beans (produced in Madagascar, 10mm short-shaft chopped product), perform column circulation extraction at 80°C for 6 hours, and cool to 30°C. Using a suction filter pre-coated with 300 g of cellulose powder on No. 2 filter paper (the cut-off particle size of ADVANTEC company is 5 μ, 30 cm), suction filtration was performed at a constant pressure (the degree of reduced pressure was 13.33 KPa), and 3750 g of clarified vanilla was obtained. Extract (comparative product 1: pH 4.7).

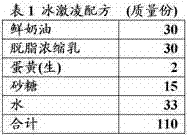

[0056] Put 300g of vanilla extract (comparative product 1) into a 1L autoclave, add 300g of fructose glucose syrup (same weight as vanilla extract) mixed with granulated sugar, and heat it while stirring after airtight, at 140 (± 2 ...

Embodiment 2

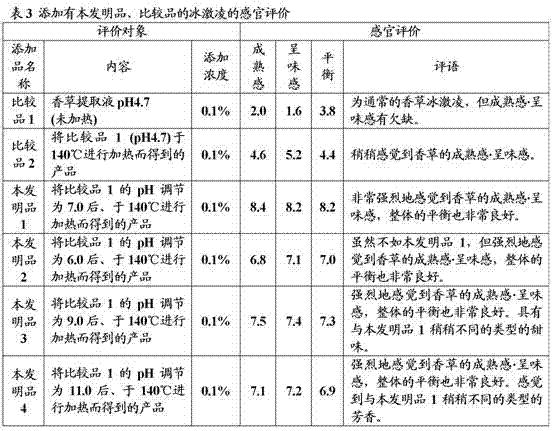

[0068] (Example 2) Study of pH

[0069] In this invention product 1, the pH when 300 g of vanilla extract (comparative product 1) was mixed with 300 g of fructose glucose syrup (same weight as vanilla extract) and then prepared with 30% sodium hydroxide aqueous solution It was made into the value of Table 3, it put into a 1L autoclave, and after airtightly sealing, it heated, stirring, and heated at 140(±2) degreeC for 2 hours. After cooling to 30° C., the contents were taken out, filtered through 100 mesh Saran, and heat-treated products (products 2 to 4 of the present invention) were obtained.

[0070] Each heated product was added to the ice cream with the same formula (Table 1) as in Example 1, and a well-trained 10-member panel conducted sensory evaluation. Evaluation criteria were carried out in the same manner as in Example 1.

[0071] The results are shown in Table 3.

[0072] [table 3]

[0073]

[0074] As shown in Table 3, the products 1 to 4 of the present in...

Embodiment 3

[0075] (Example 3) A product obtained by heating concentrated vanilla extract after enzyme treatment

[0076] (1) Preparation method

[0077] 3 Kg of frozen ground vanilla beans (manufactured in Madagascar) were thrown into 15 Kg of ion-exchanged water. 15 g (0.5% relative to vanilla bean) of cellulase T "Amano (アマノ)" 4 (cellulase produced by Amano Enzyme Inc.) and 15 g (0.5% relative to vanilla bean) were added. %) pectinase G "Amano (Amano)" (Pectinase manufactured by Amano Enzyme Inc. (Amano Enzyme Company)), stirred at 45° C. for 3 hours to perform enzyme treatment. After the enzyme treatment, it was heated to 90°C to inactivate the enzyme, 15Kg of 95% ethanol was added thereto, and it was stirred and extracted at 62°C for 3 hours. Cool to 30° C., use a suction filter pre-coated with 350 g of cellulose powder on No. 2 filter paper (advantec company’s cut-off particle size is 5 μ, 30 cm) to carry out suction filtration at a constant pressure (the degree of reduced pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com