Installation method for steam turbine sleeving type cylinder lantern ring

An installation method and cylinder liner technology, which is applied in the field of mechanical processing, can solve the problems of complex installation method and low efficiency of steam turbine sleeved cylinder liner rings, and achieve the effects of convenient heating temperature and expansion, simple operation process, and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

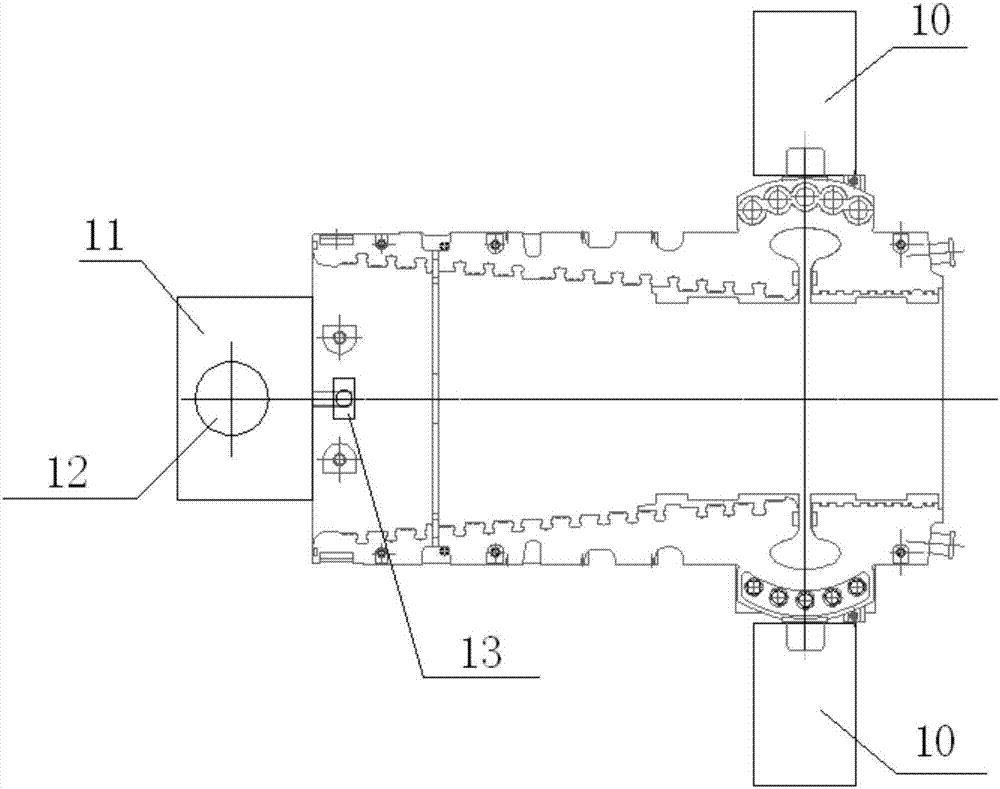

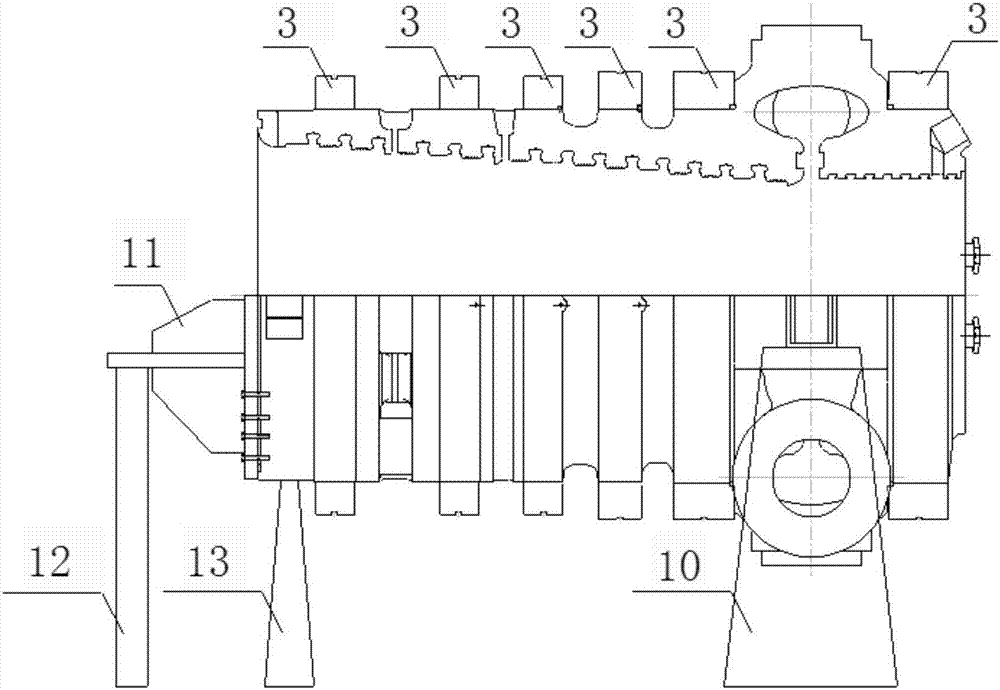

[0014] Specific implementation mode one: the installation method of the set-up cylinder collar of the steam turbine in this embodiment is implemented according to the following steps:

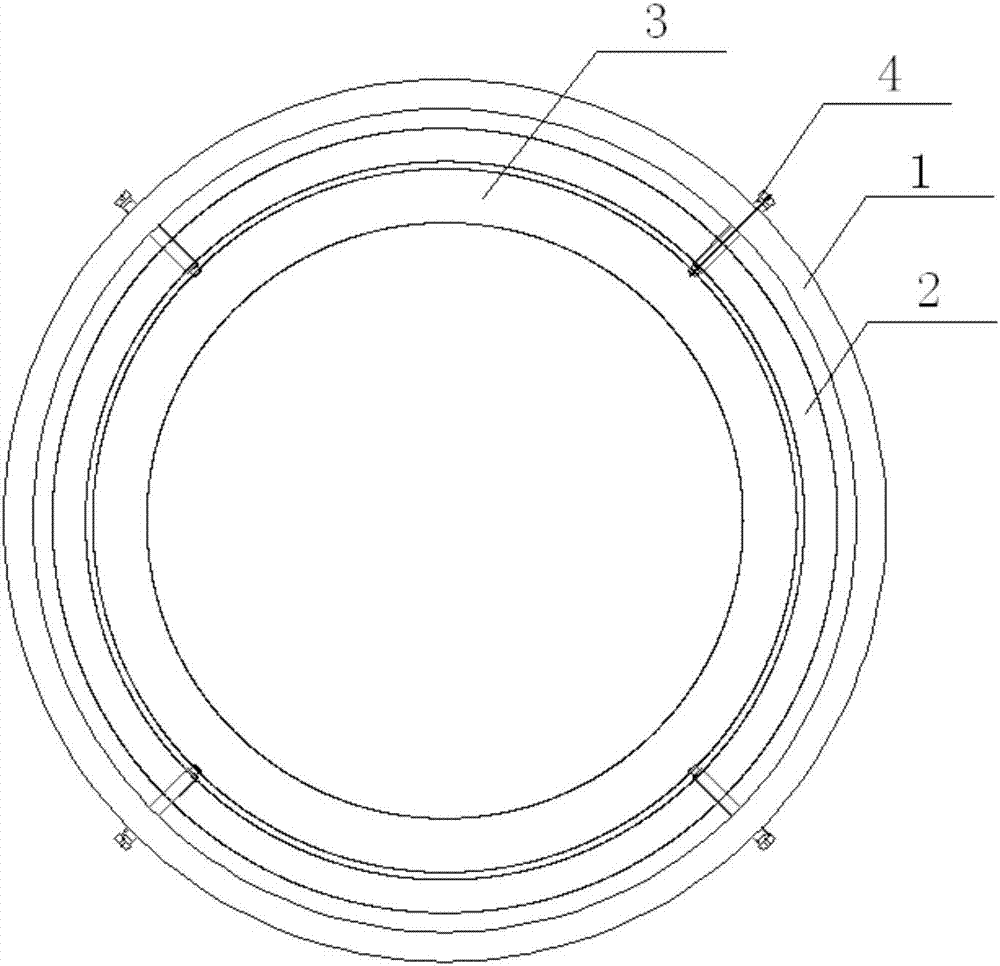

[0015] 1. A heating ring 2 is set inside the ring of the lifting ring 1, and a collar 3 is set inside the ring of the heating ring 2. There are multiple bolt holes on the circumference of the lifting ring 1 and the heating ring 2, and the bolts are tightened. 4 Insert the bolt holes of the lifting ring 1 and the heating ring 2 in the radial direction to fix the position of the heating ring 2, push the tightening bolts 4 into the outer circular groove of the collar 3, and ensure that each tightening bolt 4 and the annular groove The expansion space is reserved at the bottom to obtain the collar assembly;

[0016] 2. Place the cylinder horizontally, use fixed supports on the left and right sides of the rear of the cylinder, and use mobile supports on the front of the cylinder to complete the fixa...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the material of the lifting ring 1 and the jacking bolt 4 in step 1 is 1Cr18Ni9Ti. Other steps and parameters are the same as those in Embodiment 1.

[0021] In this embodiment, the lifting ring 1 and the jacking bolt 4 are made of non-magnetic materials to prevent induction heating.

specific Embodiment approach 3

[0022] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the heating ring 2 is formed by winding a copper resistance wire around a heating ring. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com