A Vibration Reduction Method Oriented to Vehicle Engine Vertical Vibration

A vertical direction, engine technology, used in vehicle components, power units, instruments, etc., can solve problems such as errors and error characterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0113] The present invention will be described in detail below in conjunction with the accompanying drawings and numerical calculation examples.

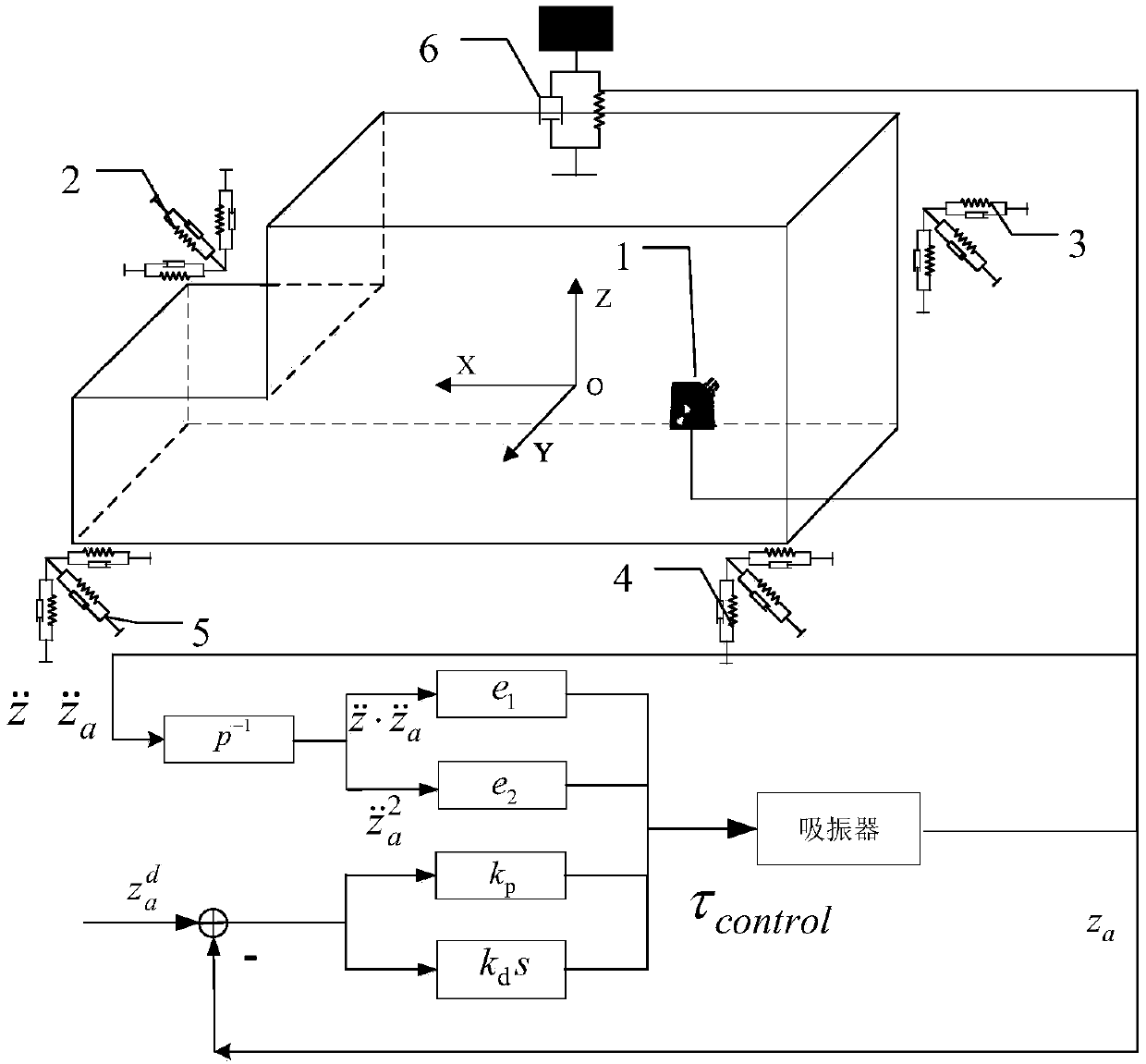

[0114] The invention proposes a semi-active damping method based on internal resonance for the vertical vibration of a vehicle engine, including engine modeling with a direct-acting vibration absorber and internal resonance analysis. In order to clearly and concisely illustrate the vibration reduction method proposed in the present invention, a simplified model is used here instead of a specific engine model. The specific steps of the method are as follows:

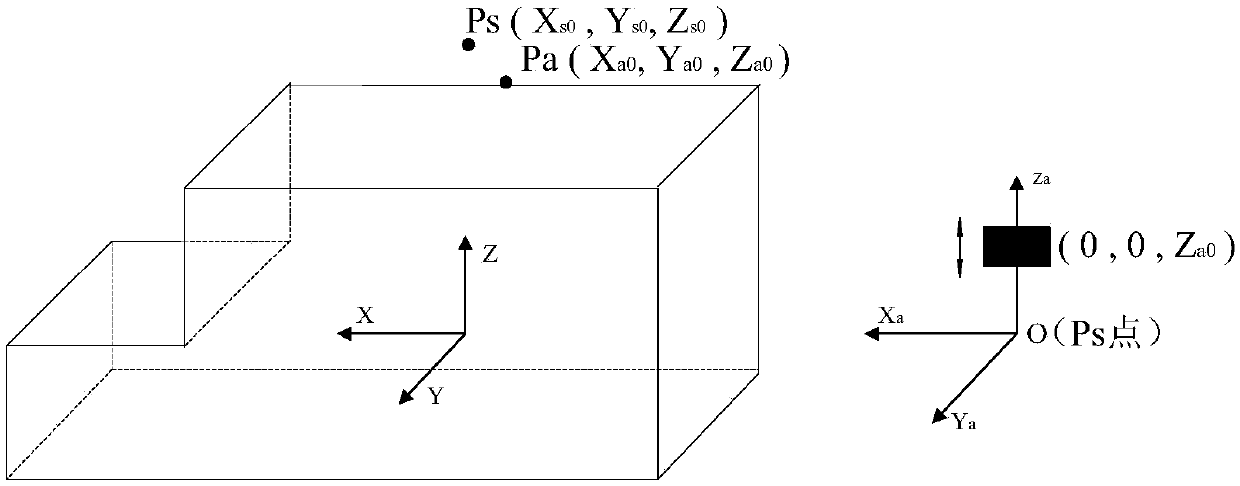

[0115] Step 1: Establish a coordinate system for the engine included in the direct-acting vibration absorber, and specify the coordinate direction on which the direct-acting vibration absorber acts.

[0116] like figure 1 As shown, establish the coordinate system of the engine dynamics model.

[0117] Define the Go-xyz coordinate system at the center of mass of the engine. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com